Supply chain logistics risk is complex, varied, and constantly changing. Businesses are constantly aiming to improve their logistical efficiency, trying to find places to cut costs and time, all while maintaining and exceeding customer expectations. But efficiency is just one piece of the supply chain puzzle—and not even the most important one. In fact, efficiency may introduce significant logistics risk to your business when it’s faced with a disruptive event. Instead of making efficiency your core methodology, focus on logistical resilience to build agile and durable supply chains.

Why resilience is better for logistics risk

Supply chain logistics managers have traditionally been focused on efficiency, attempting to reduce time and, therefore, costs, with customer satisfaction dictating metrics. In this vein, there have been great advances in logistical efficiency, as evidenced by businesses around the world adopting Toyota’s revolutionary just-in-time inventory approach. But these kinds of approaches don’t provide any bulwark against disruptions, creating efficient but potentially very fragile supply networks.

DOWNLOAD THE FULL LOGISTICS WHITE PAPER NOW: FREE PDF

A resilience-based approach to logistics could increase shipping times and costs in the short term, but it ultimately grants businesses better long-term flexibility and profits. Resilient logistics operations are better prepared in the face of major disruptions and are equipped to deal with changing regulations on carbon emissions. Focusing on resilience, therefore, ensures that efficiencies are built with adaptability in mind, giving companies the ability to withstand short-term disruptions and turn rapidly and smoothly to plan B, plan C, or even plan D to mitigate longer disruptions. Investing in resilience is an investment into business continuity in the face of an ever-shifting supply chain landscape.

This move to resilience marks a larger shift within the supply chain ecosystem, as companies work to be the most reliable suppliers instead of only focusing on speed. Of course, delivering quickly is still an important metric. However, customers are increasingly choosing suppliers that can fulfill their contracts reliably, meeting a promised delivery date even in the face of disruptions. By choosing to focus on resilience, businesses can offer realistic estimates for shipping products, providing customers with a sense of security and trust.

How resilience works for logistics risk

Resilience in supply chain logistics can take many forms and is dependent on real-time, ongoing data. Without a complete understanding of the full landscape of a supply chain and the events or disruptions happening within it, logistics managers run the risk of depending on alternative plans that may not appropriately address current issues.

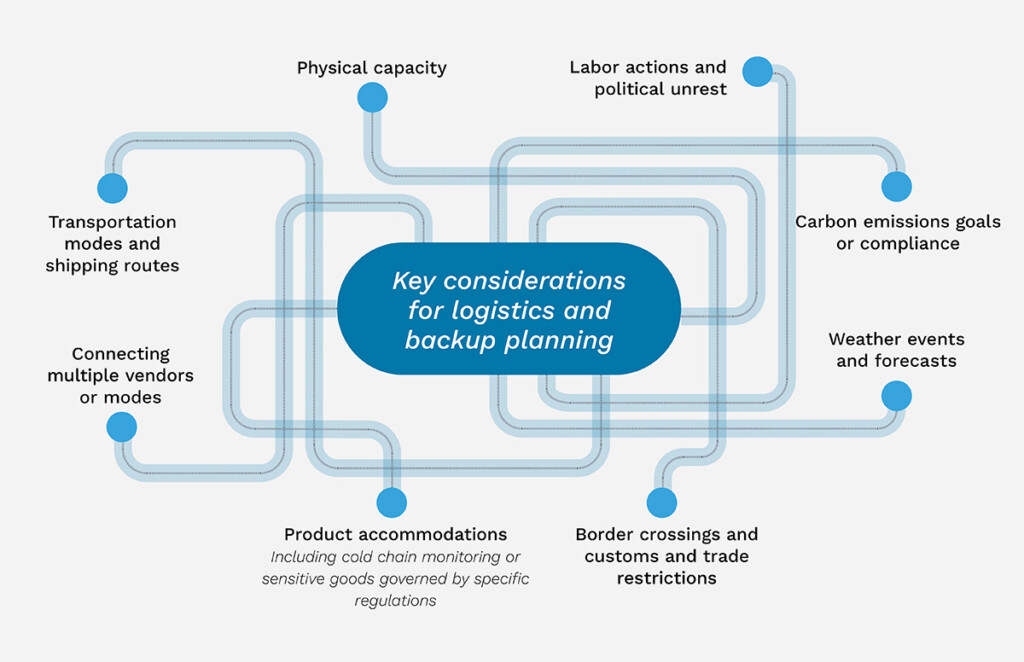

There is a wide range of considerations to evaluate in logistics planning and backup planning, which may include:

- Physical capacity

- Transportation modes and shipping routes

- Connecting multiple vendors or modes

- Product accommodations, including cold chain monitoring or sensitive goods governed by specific regulations

- Border crossings and customs and trade restrictions

- Weather events and forecasts

- Carbon emissions goals or compliance

- Labor actions and political unrest

- Cybersecurity

- and many more

Figure 1: Logistics risk can arise from multiple operational areas, requiring comprehensive supply chain risk planning.

Manually monitoring the “what ifs” and plan Bs for an ever-increasing number of variables is no longer possible. Today, it’s crucial to leverage advanced analytics to monitor, collect, and analyze the data from all of these variables. Coupled with human oversight from experienced data scientists who understand the nuances within supply chains and ongoing risks, AI takes the guesswork out of logistics risk management.

Pairing technological analysis and human oversight is ultimately what will give companies the ability to move quickly and make effective logistical decisions. Data analysis alone, for example, may not account for nuances within a business’s operations, while supply chain managers alone may miss crucial details. Combining the two provides the assurance that all details have been considered and that good logistical decisions can be made with confidence.

Supply chains can be thrown off course as easily as a storm can cause logistical disasters. But, with real-time monitoring and analysis directed by supply chain managers who understand the situation at hand, logistical nightmares can become operational success stories.

How resilience pays off for logistics risk

Companies that only focus on efficiency will soon find that they have no feasible buffer in the face of disruption. The resulting costs can be sizable, and the erosion of customer trust can lead to lost business.

But prioritizing resilience doesn’t mean giving up on the value that efficiency offers. Resilience-led decisions can point to more reliable lanes, for example, or lower-cost modes.

Following are some examples of business-focused supply chain management scenarios that create significant value through resilience instead of simply enhancing efficiencies.

Navigating port delays

Port delays and closures often disrupt logistics and send managers scrambling for backup plans. For example, when the Port of Los Angeles and Port of Long Beach experienced shipping delays during contract negotiations, shipments floated offshore during frequent work shutdowns.

DOWNLOAD THE FULL LOGISTICS WHITE PAPER NOW: FREE PDF

In a traditional efficiency-based response, logistics managers would re-route to the closest port. Shifting to the Port of Oakland seems like a quick and easy option, but it’s also an obvious option for every other company shipping in and out of the disrupted ports. In these scenarios, nearby alternate ports quickly become backed up as well.

In a more resilient plan B, a logistics manager would analyze the high-risk potential for backups at the closest alternate ports, then look at lower risk for more distant ports and their connected ground transport options. It may turn out that a Gulf Coast port has the most reliable combination of port times and ground shipping, which enables the company to commit to a specific delivery date with confidence without turning to costly air freight options.

Cold chain management

Food, cosmetics, medicines, and other sensitive shipments can be ruined by temperature fluctuations. But spending more than needed on cold-chain shipping equipment and lanes can erode profits. Risk management data can help guide decisions on delivery dates, routes, and equipment for cold-chain shipping.

For example, Campbell’s Soup had shipments that froze every year due to weather conditions along their routes, resulting in major losses of product. With ongoing data science monitoring and applied meteorology expertise, they were able to predict when weather patterns presented a relevant risk. Logistics managers were able to change shipment equipment and/or routes for at-risk product ahead of time instead of scrambling when the weather changed en route.

Making informed, resilience-focused decisions allowed Campbell’s to protect product and meet delivery dates, benefiting their bottom line. Creating a resilient, agile supply chain ultimately contributed to the efficiency of its logistics.

Carbon emissions compliance

Companies are tracking carbon output, especially when it comes to transportation, and many have made pledges to reduce their emissions by 2030 or 2050. The companies that haven’t already made pledges will soon be compelled to by upcoming legislation, regulations, and stakeholder expectations. Customers are increasingly looking for ESG-friendly suppliers to minimize their own risk profiles and carbon use.

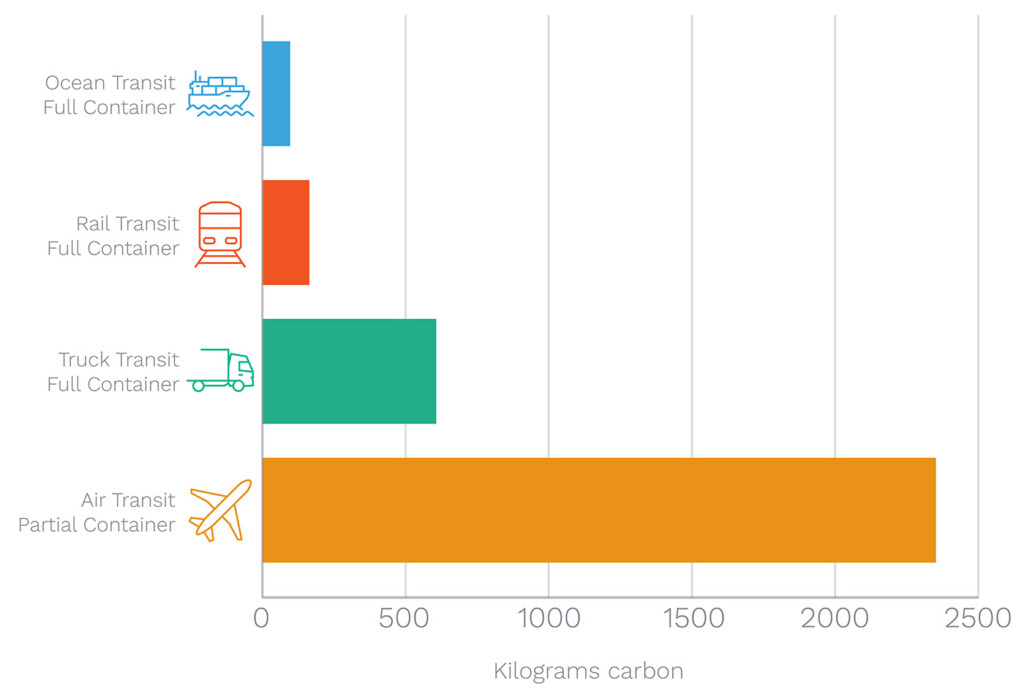

Figure 2: Accurate and complete emissions data helps managers select lower carbon impact options, as captured here for transportation from Warsaw, Poland to Paris, France (source: Everstream Analytics).

Companies that leverage risk management data to help meet emissions obligations can capitalize on several other benefits to increase value. For example, understanding which low-carbon shipping method works best for a product sooner rather than later means that supply chain managers can ensure freight capacity ahead of other competitors. Additionally, adjusting other variables, such as container size, route, or shipping timings, can lower emissions and will improve logistical efficiency and resiliency, providing crucial information in case of any changes within the supply chain.

As logistics managers start to tackle this problem, they’ll need to be able to make effective decisions based on relevant data analysis. Switching transportation methods, such as using rail shipping over truck, shifting underloaded full truckload to less than truckload shipments, or understanding where the extra product should be provisioned are helpful buffers to climate events, labor disruptions, or changes in legislation. And in the long term, logistics managers will have to make strategic decisions to potentially nearshore certain key components or products or implement several alternative, flexible plans to be able to quickly shift the flow of goods from and to different locations in the case of a disruption.

Materials inventory management

Understanding how materials shipments are moving between company locations is key to limiting production interruptions. Having insight into how regular shipments are performing will allow your company to adjust the amount of product stored at specific locations in case of any product shortages and subsequent delays along the way.

Data analysis can help companies understand if material inventory is adequately distributed for production, giving supply chain managers the information to maximize efficiency while still providing a buffer in case of disruptions.

By tracking the variables that may affect the supply chains of their key suppliers, procurement professionals can be better positioned to make strategic decisions, such as pre-ordering materials or ensuring receipt of the first shipment of materials after a delay. This kind of lead time makes it possible for companies to gain a competitive advantage, giving them a first-mover advantage for materials, minimizing any disruption.

Alternative plans need to be made from risk assessments done in real time, not biased by strategies used in the past. Comprehensive and relevant data allows companies to make the most reliable decisions instead of the easiest-looking ones.

On-time delivery

One of the most important, but often least reliable, segments of the supply chain is the final delivery to the customer. Whether these be last-mile less-than-truckload shipments, full-truckload from a warehouse or a supplier, or expedited air freight of cold chain goods, the quality of all the previous supply chain steps is often measured in the performance of delivering to customers.

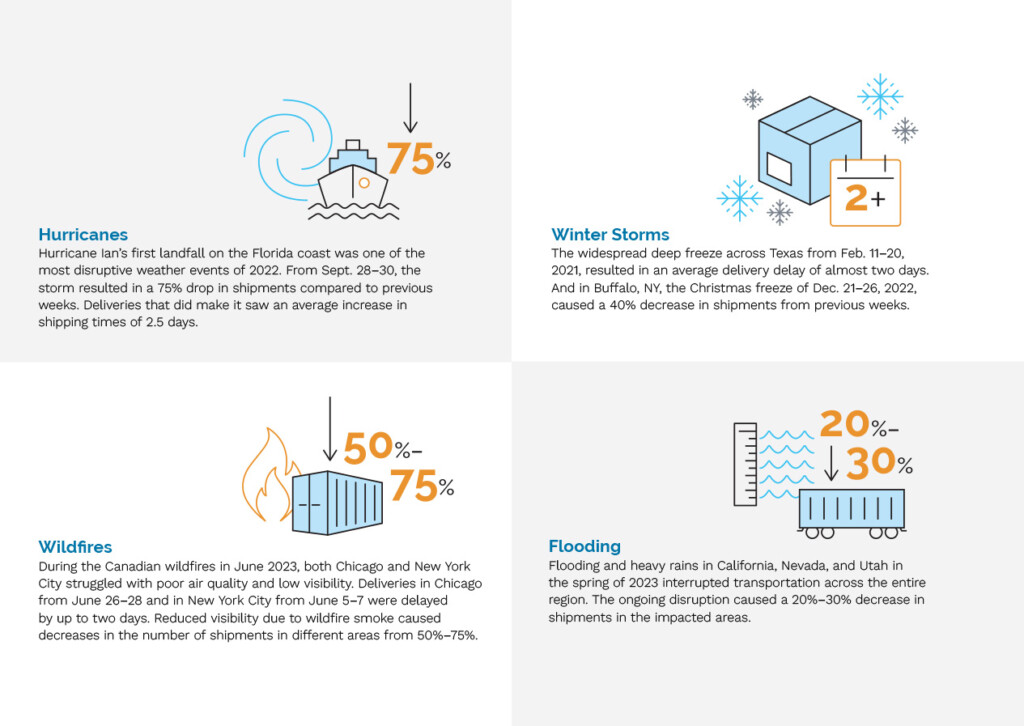

Figure 3: Extreme weather events driving logistics risk are growing in frequency and impact, costing companies money in delivery delays and cancellations (source: Everstream Analytics).

There are often very few changes that can be made to a shipment once it is in transit, making it critical to logistics planning to start with the most reliable shipment options that meet a delivery’s needs. But as we all know, even the best-made plans can fail. Understanding what is happening in real time to shipping lanes and routes allows logistic professionals to make the best decisions on re-routing, re-shipping, or updating delivery promises when faced with a disruption.

The visibility into current and alternative shipping modes, routes, and lanes gives operators the most flexibility to get a delivery back on track, increasing the likelihood of keeping customer delivery promises and avoiding costly penalties. The most resilient supply chains build in flexibility where it’s needed and the ability to quickly assess the pros and cons of backup options.

Conclusion

When it comes to logistics risk, don’t be penny-wise and pound-foolish by focusing on efficiency alone. Reliability is what keeps customers happy and penalty costs low. Reshaping supply chain logistics with resilience and agility in mind creates the conditions in which companies can ensure business continuity in the face of uncertainties.

DOWNLOAD THE FULL LOGISTICS WHITE PAPER NOW: FREE PDF

Heather Kosztowny is the Director of Data Science for Everstream Analytics, leading development and implementation of transportation modeling and optimization insights. Her 15 years of experience in data analytics and modeling have focused on logistics issues and carbon emissions evaluations and insights.