Carbon intensity adjusts evaluations of carbon emissions for business success. As the company grows in terms of production, shipments, square footage, etc., emissions can be tracked and managed. CO2e will increase as business grows. However, we don’t want CO2e to double as business growth doubles. Using raw carbon evaluations can make it hard to determine if carbon initiatives are succeeding as your business grows. Carbon intensity metrics are helpful in guiding business decisions and carbon reduction projects.

Figure 1: Carbon reduction goals for supply chain management can be measured by business metric.

Why carbon intensity matters for supply chains

The desire to reduce carbon in the business world has gone mainstream. By Dec. 2021, 622 of the 2,000 largest public companies in the world had created net zero strategies. Net zero approaches strive to counterbalance greenhouse gas emissions produced in business operations with an equal reduction in emissions elsewhere or by finding alternative methods of energy usage and production techniques that do not produce CO2e.

Reaching net zero and reducing carbon requires investment in new technologies, practices, and finances. McKinsey reports that “…spending on physical assets on the course to net-zero would reach about $275 trillion by 2050.” They add that not all the spending should be considered a cost and that investment needs to start now. This highlights the importance of understanding carbon emissions produced in the context of business metrics and growth.

As public and government attention on reducing carbon emissions increases, businesses and financial institutions will prioritize resources toward carbon tracking and reduction strategies. Columbia Climate School reports that over 450 financial firms have pledged $130 trillion in private capital to offset the costly endeavor. That’s a good thing because reaching the goal of net zero by 2050 in the U.S. will require significant investment.

This staggering level of spending should yield a business return.

The benefits of reducing emissions can go beyond being good and concerned global citizens. A carbon intensity strategy can pay off in profit margins, competitive advantage, and sales performance.

Compliance and regulations

For Scope 3 compliance, companies must report all direct and indirect emissions that occur in their value chain. This includes the entire process of making and transporting products and providing services. In addition, countries around the globe are demanding that their national corporations become net zero sooner, not later. Finland has the earliest target of 2035. China, the most populous nation on Earth, has 2060 as a target. Although few countries have yet determined enforcement methods, at some point, companies will be required to reach net zero to maintain future operations across the globe.

Competitive advantage

Over the last few years, multiple surveys have shown that consumers want the organizations they do business with to be good environmental stewards, and companies that meet this expectation are benefiting. A McKinsey survey found that 60% of American consumers would pay more for a product with sustainable packaging. A recent study found that products making ESG-related claims averaged 28% cumulative growth over a five-year period versus 20% for products that made no such claims.

Goal setting

Every company motivates teams by setting growth goals according to various sets of metrics. For supply chains, this mindset can be applied to improving efficiencies that can be measured by monitoring carbon intensity levels. For example, a supply chain goal could be doubling growth while reducing carbon intensity level (and related expenses) by 40%.

Company culture and recruiting

Gen Z and millennials are more concerned than previous generations about the climate and are more engaged in the conversation. With future generations prioritizing the need for climate action, companies can build a stronger culture by highlighting emissions reduction. Companies that emphasize carbon intensity reduction are also better positioned to appeal to the next generations of recruits.

Sharing with stakeholders

Companies can stand out to stakeholders, including investors, by their commitment to net zero and lower carbon intensity. Public companies, shareholder funds, and investors are all creating environmental investment portfolios because shareholders are increasingly drawn to companies that share their concerns. Both internal and external stakeholders (current and potential) are more often asking their employers and partners about carbon emittance rates and policies.

Benchmarking operations

As companies strive to meet regulations or internal goals, they need benchmarks. Marking the carbon intensity of a particular unit of activity gives companies a very specific measure. That makes it easier to compare the carbon intensity level at different times to gauge progress or compare it to different operational efficiencies and practices.

Sales support and collateral

As Scope 3 emissions calculations and other emissions regulations become more prevalent, business-to-business relationships will prioritize alignment on principles and goals for carbon emissions reductions. Being able to document that they are purchasing from a company with effective climate change policies could make the difference in choosing among potential suppliers. The same “halo effect” can apply to your own suppliers, partners, and transportation providers, who can publicize their support for an environmentally friendly customer.

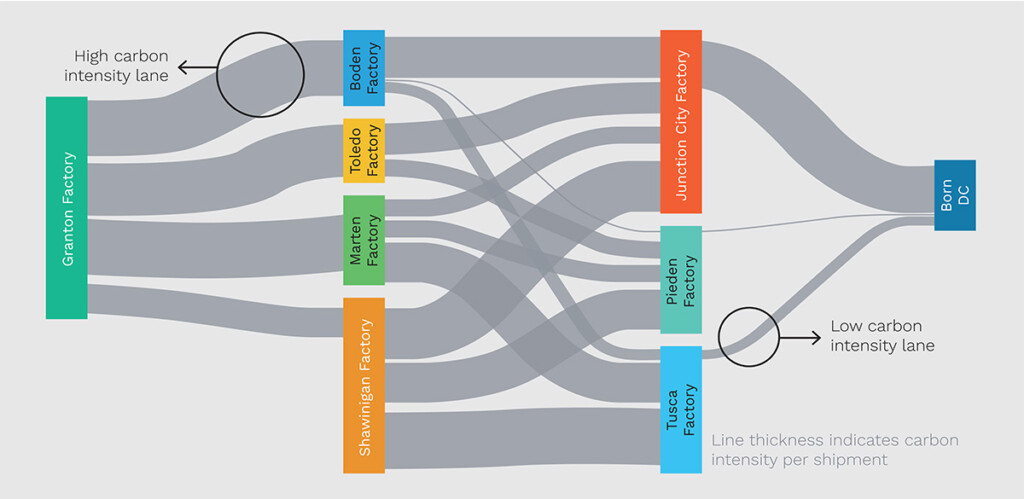

How to measure carbon intensity for supply chains

Capturing carbon intensity starts with an accurate measure of carbon emissions production in each stage of the supply chain. Carbon intensity can then be calculated for the whole supply chain or for specific sections like inbound materials, manufacturing processes, and outbound logistics.

𝑐𝑎𝑟𝑏𝑜𝑛 𝑖𝑛𝑡𝑒𝑛𝑠𝑖𝑡𝑦 = 𝑡𝑜𝑡𝑎𝑙 𝑐𝑎𝑟𝑏𝑜𝑛 𝑒𝑚𝑖𝑠𝑠𝑖𝑜𝑛𝑠 / 𝑏𝑢𝑠𝑖𝑛𝑒𝑠𝑠 𝑚𝑒𝑡𝑟𝑖𝑐

Figure 1: To calculate carbon intensity, the total carbon produced is divided by the business metrics applicable to your company.

It is important to use the most accurate data available for calculating both the actual carbon emissions produced and the real values that relate to the business metrics used. For example, in measuring transportation emissions, accurate carbon emissions values include not just the distance traveled but details like actual fuel consumption, which accounts for effort due to engine efficiencies, delays, wind, waves, and tides. Values for business metrics should be evaluated retrospectively to account for changes like canceled orders or shipments rather than relying on forecasted or budgeted values.

There are several options for business metrics to consider using to calculate carbon intensity.