Since the U.S.’s Uyghur Forced Labor Prevention Act (UFLPA) came into effect in June 2022, U.S. Customs and Border Protection (CBP) has already seized nearly $1 billion worth of shipments for violating the new act. Preparing for and responding to UFLPA implementation has become mission-critical for supply chain managers.

Understand the UFLPA implementation and enforcement by U.S. Customs (not just from China) and how your operation can smoothly navigate the legislation.

A look at the history and impact of UFLPA implementation

The UFLPA aims to end forced labor by the Uyghur population in China and other ethnic minorities by banning the import of goods produced in the Xinjiang region of China, and requiring businesses to report global supply chain details to prevent the use of forced labor entirely.

With these thorough reporting requirements in place, it is essential that businesses have visibility into every part of their supply chains. Visibility will not only be key to maintaining compliance with the UFLPA, but also give businesses the ability to quickly adapt if forced labor is found within their supply chains.

Even if your business doesn’t have obvious ties to the Xinjiang province, you may find that your company may still be affected by the UFLPA. Chinese companies are shifting names, locations, and sub-tier supplier connections to avoid obvious UFLPA violations, and many border seizures are for imports from other Asian countries.

Implementing a risk management strategy for UFLPA Compliance will be key as global business adapts to higher human rights standards.

How UFLPA Implementation Affects Product and Material Seizures

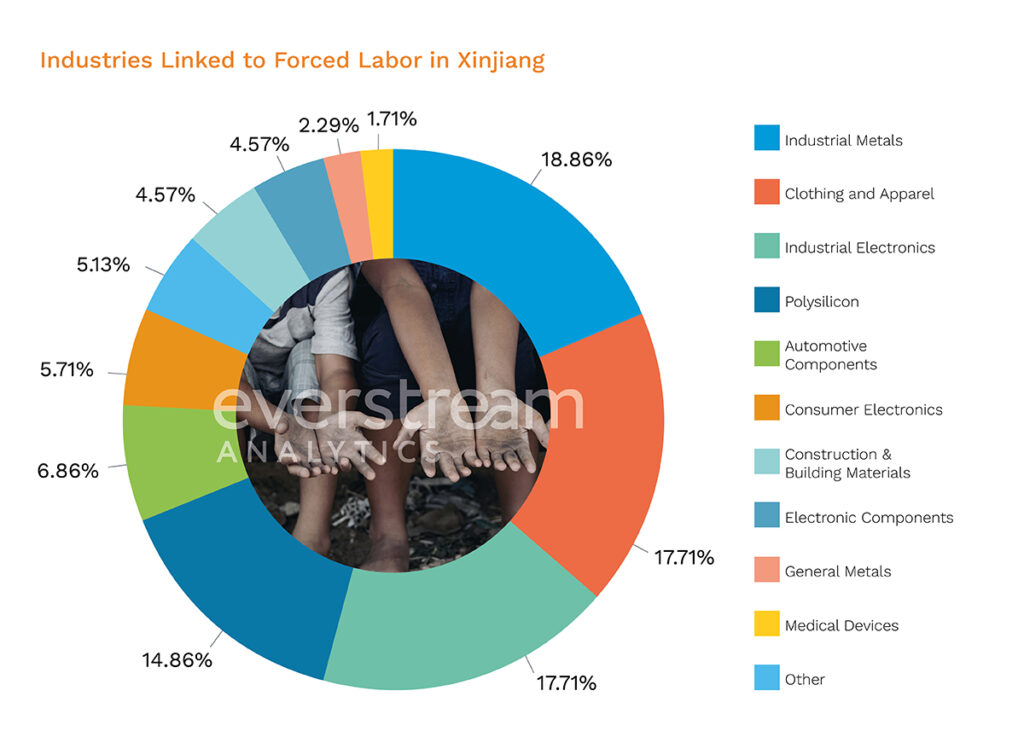

A wide variety of sectors are affected by the UFLPA, as the Xinjiang region is responsible for several important raw materials exports and production of finished products across industries, including cotton, tomato paste, and poly silicon. The main industries directly impacted by the UFLPA are the food and beverages sector, clothing and apparel industry, and silica-based manufacturing businesses.

So far, most seized shipments reported by CBP are from the electronics industry, followed by the apparel, footwear, and textiles industry, and industrial materials. The automotive and solar panel industries are also running into trouble as they use silica-based products, including aluminum alloys, silicones, and quartzite.

This doesn’t mean other industries are off the hook. Silica-based products, for example, include aluminum alloys and silicones, which are present in many other finished supply chains, including automotive and solar panels. As global supply chains have become increasingly complex, it’s very possible to have links to a supplier in the Xinjiang province. In fact, CBP data reveals that most shipment seizures haven’t originated in China, but rather countries including Malaysia and Vietnam, indicating that human rights issues can be hidden deep within the sub-tier network. Therefore, sub-tier visibility is key to ensure compliance with the UFLPA, even for businesses and industries that don’t have any obvious link to government UFLPA entity list.

Border controls and their role in UFLPA implementation

Customs and Border Protection’s purvey includes examining and holding imported products, inspecting them in accordance with regulations and issuing WROs when necessary. Therefore, the CBP is responsible for enforcing the UFLPA.

When a company is subject to a seizure, the CBP issues a Withhold Release Order (WRO), a directive ensuring that items suspected of production through forced labor are held at the port of entry. A list of WROs can be found on the CBP website, where it is periodically updated with information including the name of the business, type of merchandise, the date the WRO was issued, and the status of the WRO, with an accompanying press release.

With consumers increasingly aware of human rights issues inherent in supply chains, it’s not only finances that are at risk when the CBP issues a WRO. The reputational damage to a business can also be difficult to recover from as consumers move to competitors with cleaner track records instead.

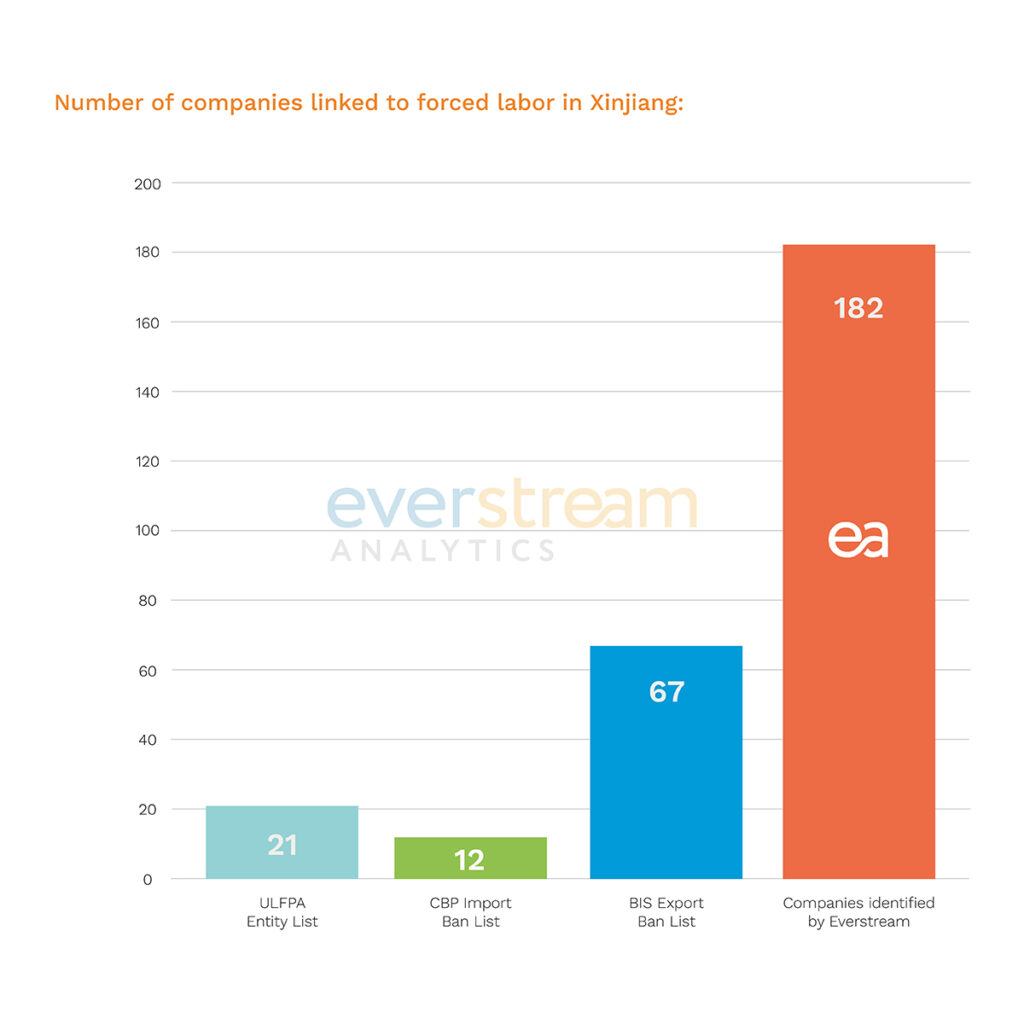

Create an implementation strategy beyond the UFLPA entity list

To this end, the CBP also publishes the UFLPA Entity List, a public register notifying the public of banned manufacturers within the Xinjiang province. While this is a valuable reference point, the UFLPA Entity List is hardly comprehensive. That’s why it’s important to consider a variety of sources when amping and re-shaping supply chains. Outside investigators, including media outlets, NGOs, and more, are continuously searching for evidence of forced labor. Including these data sources in any UFLPA risk management strategy can protect businesses from the sudden shock of a non-compliant or even banned critical supplier.

What’s next for UFLPA

CBP has recently released enhanced regional alerts within their Automated Commercial Environment (ACE) platform to ensure businesses are notified quickly about new developments or discovery of goods with origins in Xinjiang. As CBP continues to enforce the UFLPA, they will continue to provide updated guidance to importers to ensure compliance and minimal disruptions to businesses and supply chains.

With enforcement of the UFLPA in full swing, businesses must understand the extent and impact of their global supply chains, down to the very last sub-tier supplier. Ultimately, with similar regulations from the EU and Germany coming into force, this won’t just be an issue for US importers and businesses.

Mapping out your global supply chain to recognize potential forced labor risks will be crucial in preventing UFLPA violations. Remember, ignorance is no excuse, so disregarding any risks is not a strategy, but rather a recipe for failure. Having the tools to make educated decisions about your supply chain, adjusting suppliers as necessary, will go a long way to avoiding costly fines due to non-compliance and preserving your business’s reputation with customers.

Watch our webinar to learn how technology can support your UFLPA strategy