Even with your best efforts, which are likely significant, your organization will still experience common issues that cause delays, partial deliveries, and suboptimal quality, all of which cause disruptions in your ability to deliver your products or services to your customers. By regularly turning to your supply chain network design process, you will be better able to respond to such issues and improve your supply chain to minimize issues as much as possible. Doing things as they have always been done goes out the window.

The benefits of optimizing your supply chain network

The purpose of supply chain network design is to strengthen your supply chain by not only through mapping and modeling but also ensuring you are optimizing every part of it, at least what you can control. Even those elements seemingly out of your control can be mitigated if they are detected early enough.

Weather events are a prime example. You cannot control Mother Nature, but you can identify a probable weather event and predict its impact on a shipment ahead of time, so you have time to respond in a way to lessen the risk.

When it comes to logistics are the planned routes optimal, given the known risks for events such as inclement weather, a natural disaster and its aftermath, infrastructure issues, or social unrest? Are you using the ideal modes of transportation for each shipment type to ensure freight won’t be damaged and costs don’t soar?

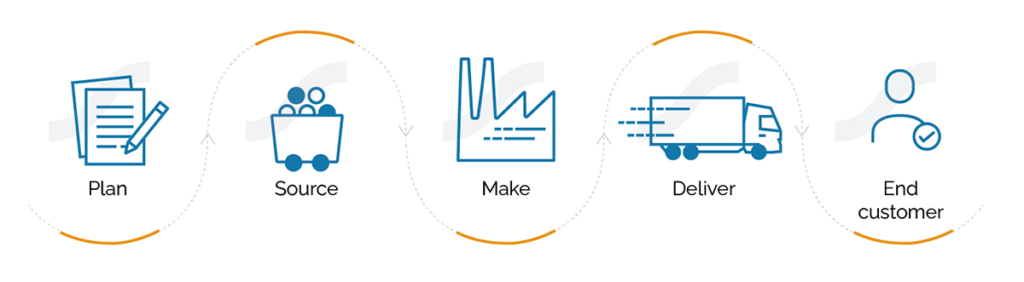

A well-executed supply chain network design forces leaders to think through every aspect of the supply chain, determining how best to design the network to enable the organization to deliver products and services on time, in full, and at the lowest possible cost. That is an optimized supply chain network.

When you can visualize your existing supply chain network, you can see issues and risks along with opportunities. Depending on your organization, you may recognize the need to add a new distribution center to your network to better serve customers or expand to new markets. This optimization may also allow you to reduce delivery times and streamline routes for a reduction in costs and improvement in customer satisfaction.

Decisions like these are only possible with the right data in hand. Supply chain network design is most successful when you bring disparate pieces of data together to formulate a complete view of your supply chain. Through modeling and what-if scenarios, leaders can manipulate the data to see every possible option before deciding on a plan.

How to design your supply chain network

As with any type of planning, you should begin with defining your strategic objectives in your supply chain network design. What is the purpose of this endeavor and what is it that you want to achieve?

For leading organizations, pleasing the end customer is priority number one. What type of customer service do your customers and potential customers want to experience? Do your customers hold you to OTIF commitments, penalizing you for failure to meet their expectations? If so, how can you meet those commitments while controlling costs? Per the example above, perhaps adding a new distribution center is the answer, or maybe optimizing routes to avoid the highest potential risks that cause delays.

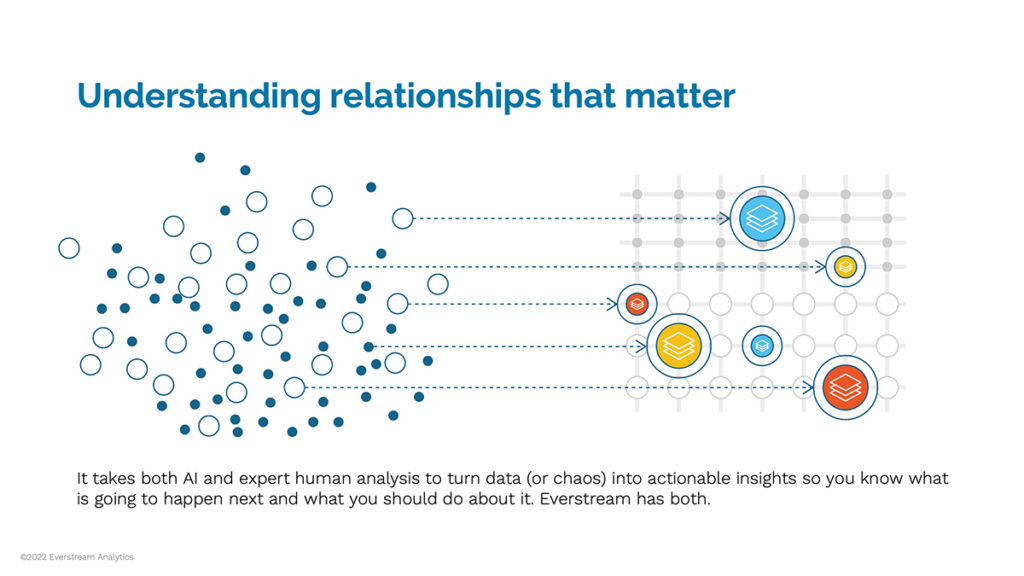

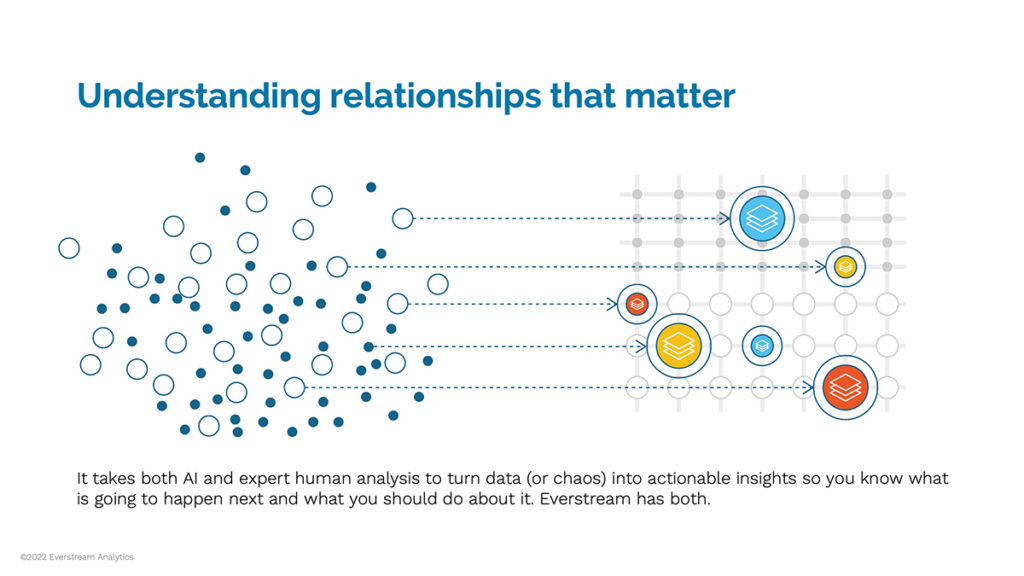

Before you can make those decisions, you need data. Trying to gather this data manually is time-intensive and risky because if you are like most organizations, valuable data is dispersed amongst multiple internal and external systems, managed in silos, and largely inaccessible. Even if you do have access, is your data reliable? Is it clean? Leaders cannot make decisions based on iffy data.

If you are using data housed in spreadsheets, that data is not in real-time. One of the downfalls of spreadsheets is that by the time you see the spreadsheet, it is already outdated. Data points are constantly changing, and while spreadsheets may do well to chronicle what has already occurred, they fail to capture what is happening right now.

Because there are so many variables and so much change that come into play, many organizations are leveraging intelligent automation and predictive analytics to manage big data in real time. Gartner says that artificial intelligence capabilities are in demand as supply chain leaders are looking for solutions to “enable automation and augmentation of supply chain decisions for both supply chain planning and execution.”

Sophisticated software can capture data from multiple systems from across the enterprise and beyond, pull out the relevant data, cleanse and validate it, analyze it, then present it in a consumable way. When your data is operationalized, you can leverage it faster and with greater confidence. Your data is no longer a risk because it is unreliable but an asset because it is fueling smarter decisions.

With the right data in hand, it is easy to move to the modeling stage of supply chain network design. For logistics, you can see where your risks lie along every route for each shipment. Risk scoring brings data to life, giving you a numerical system to rank risks based on probability and severity. You get to set your organization’s appetite for each risk so that only risks that meet your preset threshold are flagged with a higher score. For example, a risk scored with a 2 can be put on the back burner, while a risk score of 8 needs immediate attention. By prioritizing risks, you can ensure your organization is focused on the right things at the right time.

When the software identifies high-risk situations, decisions need to be made. The beauty of supply network design is that you can model alternative scenarios. For instance, you can answer, “What happens with shipment A when we change the route to B or C?” Or “What costs would we incur or save if we changed the mode of transportation from ground to air?” Modeling enables you to see each scenario and its interdependencies as you evaluate its impacts on cost, delivery times, quality, and customer service.

Through modeling, you may also be able to identify bottlenecks and areas for improvement. If a certain route has been using one lane for years but you are able to see through modeling that another lane is actually optimal, you can alter plans with confidence. Because supply chain network design is a regular process and not a one-time effort, particularly when it comes to mapping your sub-tier suppliers, you can continually refine and improve your operations in your efforts to have a sustainably optimized supply chain. Remember, your supply chain is constantly changing, requiring your supply chain network design to adapt.