Traditional risk assessment calculations involve heuristics, data analysis, and spreadsheet-based modeling all specific to the operation, time frame, and product.

- Heuristics are general rules of thumb applied to assessing supply chain risk. Heuristics help identify and analyze various supply chain metrics including performance, cost, quality, and delivery times.

- Data analysis using computer programs enables risk managers to sort through and process large amounts of information from various sources to reveal patterns and trends. With human oversight and interpretation, those trends can inform insights about various risk scenarios.

- Spreadsheet-based models outline various risk-based elements and outcomes, allowing risk managers to adjust variables to create ‘what if…’ scenarios. Variables can include whatever risk factors are in place including weather, labor issues, insolvencies, and more, revealing each factor’s potential impact on supply chain performance.

Risk managers have traditionally relied on templates as a start, then adding operation-specific inputs to create a robust system for calculating overall supply chain risk. But this process has always been somewhat manual, with managers monitoring and tweaking various inputs, and coordinating the modeling process. This approach is time-consuming and not easily adjusted over time or when risk factors change.

Risk identification

Risk identification is part brainstorming, part interviewing, and part gathering data from different systems of record. Risks can come from anywhere, but the primary risks to most organizations fall under these categories, as identified by ISO:

- Physical failure (functional failure, incidental damage, malicious damage, or criminal/terrorist action)

- Operational threats

- Natural environmental events (weather, natural disasters)

- Third-party threats

- Security threats

- Business continuity threats

- Other sources include geopolitical threats, reputational risks, and financial risks in their risk assessments.

Risk analysis

As you begin to analyze the identified risks, you are looking to qualify the causes and impacts of each risk. For instance, as a shipper, you want to know all the causes of shipment delays and what effect those delays have on your ability to meet your commitments.

You must define what is an acceptable risk both in terms of its likelihood and its potential impact on the business. The business impact is rarely isolated, as there is almost always collateral damage. A University of Maribor report on the risk assessment model says, “If we wish to effectively manage risks, we need to be aware of logistics sources that a specific risk and its consequences possibly affect.”

A flooded shipping route, for example, could impact your ability to ship products on time, which impacts customer service and your brand reputation, but it also affects inventory management and operations. If you can’t ship, you must pay to store that material which could raise costs and present a warehousing issue.

Risk evaluation

After risk identification and analysis, the next item on your supply chain risk assessment template is to evaluate the risks in a quantitative way to help you make decisions on how best to treat those risks or whether they need to be managed at all. You won’t be able to prioritize risks until you are able to accurately quantify the risks based on their probability and impact.

Risk probability is often defined as “highly unlikely,” “unlikely,” “possible,” “very possible,” and “definite.” Risk scoring is even more precise, calibrating risk with a numerical score. The easier and faster leaders can understand the risk they are dealing with, the quicker they can make decisions with a higher level of confidence.

Risk impact can also be factored in, providing a number that correlates with a risk impact being “trivial,” “low,” “moderate,” “high,” or “catastrophic.”

McKinsey says there is another dimension to risk, one that also contributes to the risk score: the organization’s preparedness to deal with that specific risk. Some organizations can manage certain risks better than others, either because of their established best practices, their technology, their people, or their budget – sometimes a combination of more than one of these components. If your organization lacks technology that automates these steps, for example, it will take it longer and require more resources to do the same work.

Scoring, based on a consistent methodology, helps leaders to visualize risks so they can determine their next action. As McKinsey says, “This allows for prioritizing and aggregating threats to identify the highest-risk products and value-chain nodes with the greatest future potential.” Monitoring these risks will ensure you have an early warning system in place to track prioritized risks so you can respond quickly.

Risk mitigation

Risk treatment is next on the supply chain risk assessment template. You can avoid some risks altogether, while others can only be mitigated. Again, it depends upon the risk, its probability and impact, and your organization’s ability to manage it.

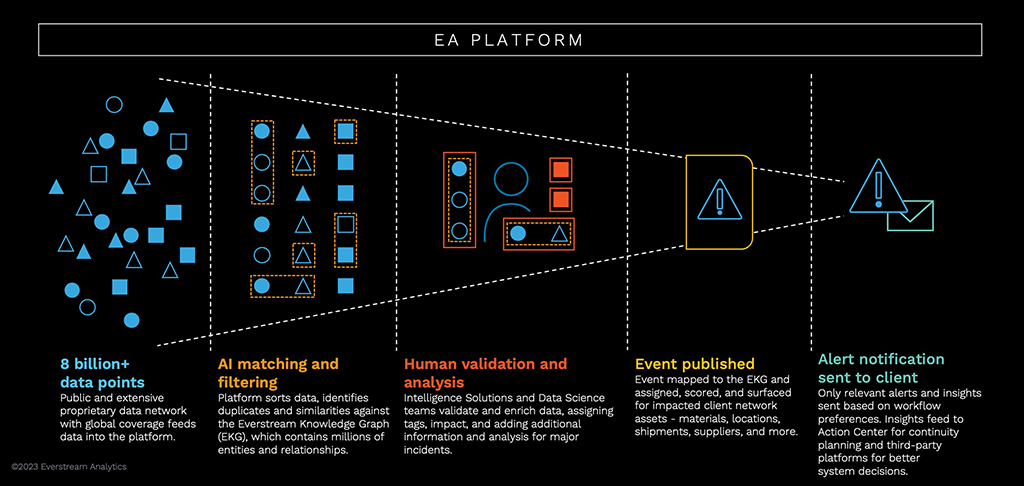

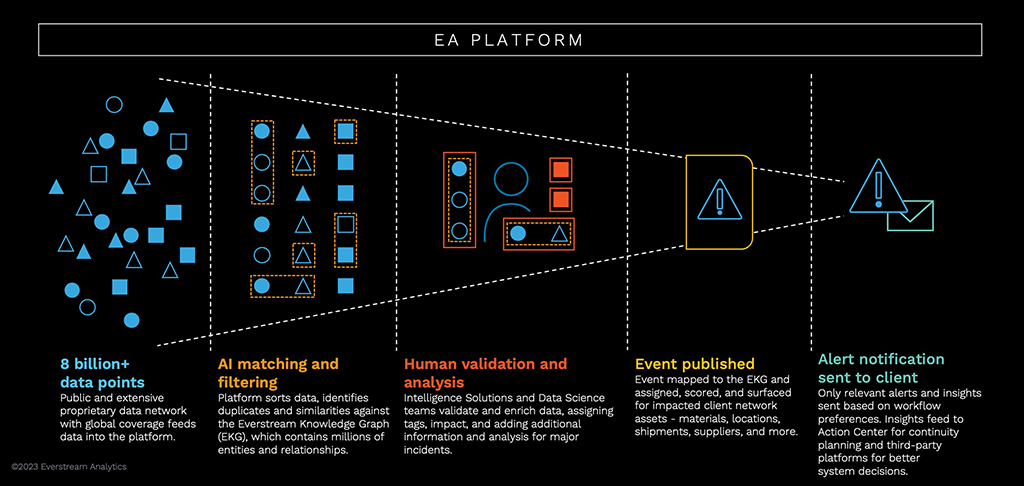

Figure 2. AI and machine learning combined with human oversight and validation forms the backbone of today’s supply chain risk assessment templates.

You must determine your organization’s thresholds for action. What will your organization tolerate in terms of impact and likelihood for each identified risk? Which risks can your organization confidently avoid or mitigate? Even those risks that appear to be out of your control, such as those that fall into the natural environmental events, can be more predictable with the right software. Remember, if you can predict a risk, you have a better opportunity to avoid or mitigate the risk.

Modern software does an excellent job at automatically and rapidly gathering data from disparate systems to identify, analyze, and score risks, as well as providing lower-risk alternatives. Instead of multiple resources spending days or even weeks on these critical assessment steps, you can focus on other things and let the software crunch the numbers for you. Leaders need only to look at the customized reports and dashboards to make data-backed decisions, saving everyone countless hours of work and providing a higher level of confidence in decisions.

AI and automated risk assessment templates

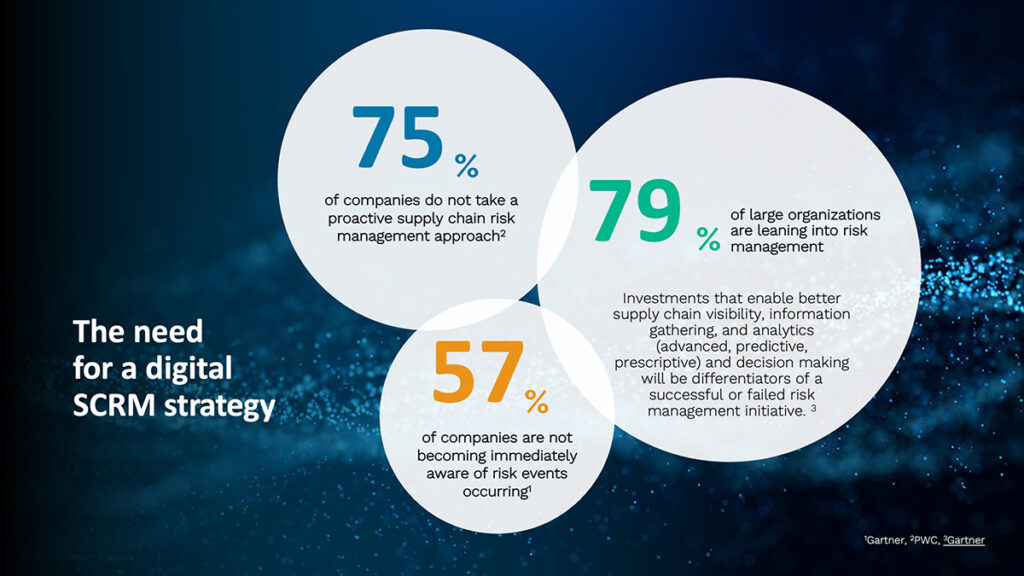

Artificial intelligence (AI) is replacing traditional risk assessment processes, and automating most of the manual duties. This frees risk managers to run more analyses, evaluate more scenarios, and create more thorough and effective plans.

Using complex machine-learning models managed by data scientists and other managers with risk management expertise, highly automated supply chain risk assessments can be developed that consider all relevant factors and generate relevant insights.

To replace your risk assessment templatized process with automated AI, here are five factors to look for:

- Comprehensive coverage: The software platform should cover all areas of your supply chain risk, including suppliers, sub-tiers, transportation, and customers. It should also consider both internal and external risks, including natural disasters, socio-political, sustainability compliance, and many more.

- Standardized criteria: The assessment criteria should be clearly defined and consistent across all areas of your supply chain. This ensures that you are comparing apples to apples when evaluating different risks. It also helps you build a standardized total risk score that can be the leading indicator for your organization.

- Flexibility: While the risk-assessment platform should have standardized criteria, it should also allow for customization to meet the specific needs of your organization. For example, you may want to add questions or adjust the weighting of certain criteria to reflect your organization’s unique risk profile and business goals. Use surveys to ask your third-party vendors for additional information to build risk scores.

- User-friendly interface: The platform should integrate easily with your existing operations and software. It should be easy to use with clear instructions, a customizable dashboard, and an intuitive interface. This ensures that the whole team can complete the assessments efficiently and effectively, and share with others.

- Actionable results: The platform should provide clear, actionable results that enable your team to prioritize and mitigate the most significant risks. This may include a risk register or heat map that highlights the most critical risks and potential mitigation strategies.

There are many supply chain risk assessment templates available, ranging from basic checklists to more comprehensive tools that incorporate advanced analytics and customizable modeling.

Applying supply chain risk assessment templates

Ultimately, the right supply chain risk assessment template for your organization will depend on your unique needs and risk profile. However, by selecting automated software that meets the criteria outlined above, you can ensure that you are conducting a thorough and effective risk assessment that enables you to proactively manage your supply chain risks.

Today’s supply chains are more complex as ever. It is imperative to build a framework to manage supply chain risks, both known and unknown. Risk assessment is never once and done. It is a repetitive process that involves different types of changing data. Organizations that seek to reduce supply chain disruptions must find ways to reduce their risk, using actionable, predictive intelligence as their foundation.