Leading companies rely on technology for automated compliance solutions including inventory management and product traceability systems. This gives all stakeholders access to accurate data about each stage of the journey for better decision-making. Software can also generate documentation for audits or inspections.

So many countries now have supply chain laws regulating labor and environmental practices that compliance has become a global standard that all businesses must follow to remain competitive.

Five steps to supply chain compliance

Supply chain compliance requires careful planning and implementation to be successful. Here are some steps for creating and maintaining a strong supply chain compliance program:

- Study all applicable regulations: Today’s global operations must understand the regulations in each region, state, or locality their suppliers or customers are. Laws can cover hiring and labor, emissions and water usage, product safety, customs operations, import/export restrictions, and more. Also study any industry-specific regulations.

- Create internal policies and procedures: Internal policies should address standards for working with supply chain partners, suppliers, and customers to ensure that all business activities meet legal, ethical, and safety requirements. Increasingly, companies are responsible legally or in the public eye for the behavior or other organizations in their supply chain.

- Run due diligence before contracts: Check partner and supplier practices before entering into agreements instead of waiting to see if problems emerge. Due diligence can include financial screening, labor practices, employer history, political climate, emissions, and more.

- Add risk monitoring and mitigation: The best automated monitoring software uses a blend of media reports, analytics tools, artificial intelligence, and subject matter experts. Monitoring platforms can alert organizations to potential and emerging risks before impacts hit the company or the public takes notice.

- Create corrective action plans: Whether a company discovers internal or external compliance risks, immediately implementing a corrective action plan can solve the problem (or document efforts) quickly.

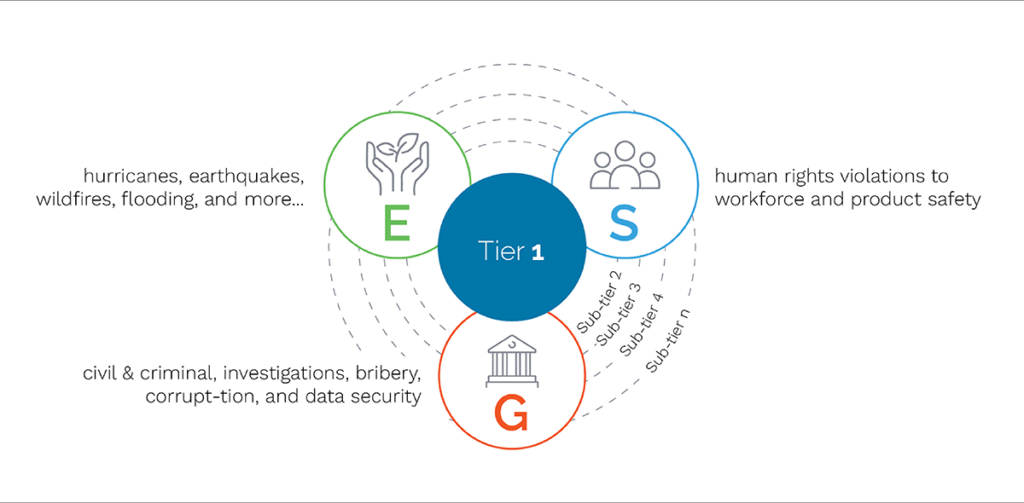

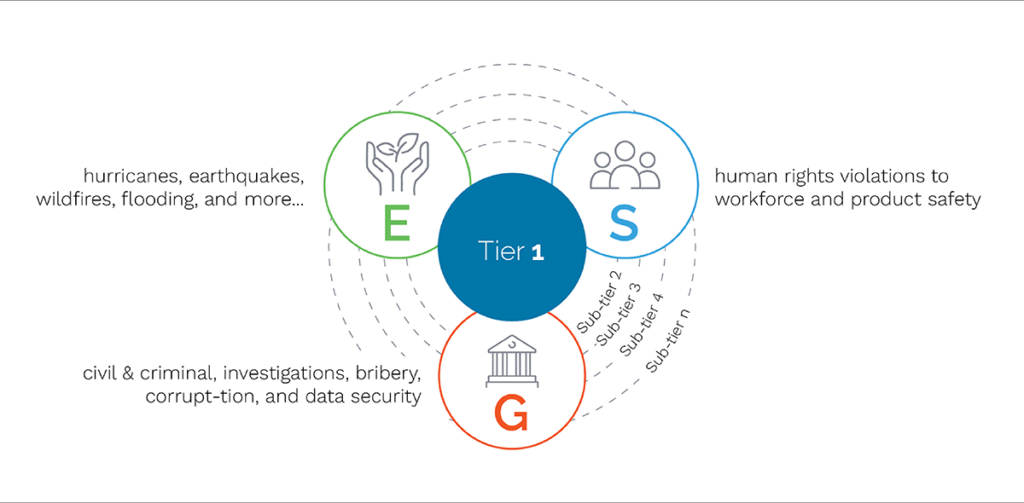

The growing importance of ESG in supply chain compliance

Supply chain laws and public scrutiny increasingly focus on environmental, social, and governance (ESG) concerns. Companies are often held responsible for not only their own compliance, but that of suppliers. What falls under “ESG” can be broad, from climate change to striking workers. Some examples of ESG issues include:

Environmental: production and consumption operations

- Climate change

- Emissions and air pollution

- Waste management

- Water usage

- Efficient energy use

- Resource conservation

- Biodiversity protection

- Sustainable agricultural practices

Social: workplace safety and other labor issues

- Wages to workers

- Health benefits

- Working hours

- Working conditions

- Collective bargaining agreements

- Child and forced labor

- Workplace discrimination

- Employment security

- Operational transparency

- Community customs and cultures

Governance: illegal activities and corporate transparency

- Corruption and bribery

- Illegal activities

- Disclosure of information

- Audit procedures

- Risk management practices

- New market entry

- Supplier contracts

- Internal processes and corporate alignment

- Reporting and documentation

Supply chain compliance is now global

It seems like every month a new or proposed supply chain law emerges.

The German Supply Chain Act (known in Germany as LkSG) passed in June 2021 and went into effect in January 2023. Phase two will go into effect January 2024. The law applies to businesses located in Germany with more than 3,000 employees worldwide; companies with a German-registered branch that has more than 3,000 employees; companies with suppliers in Germany who have more than 1,000 employees; and companies that supply products German companies with more than 1,000 employees.

France’s Duty of Vigilance applies to French companies with more than 5,000 employees in France or more than 10,000 worldwide. The law obliges companies to assess, prevent and mitigate grave human rights violations in their supply chains.

Table 1: Existing and pending global supply chain laws

| Location |

Law |

Description |

Status |

Implementation Date |

| United States |

The Fashion Sustainability and Social Accountability Act |

Targets fashion and retail brands in New York with a global revenue of >$100 million. Companies in violation subject to penalties from the NY attorney general. |

Pending in New York state legislature |

n/a |

| Canada |

Fighting Against Forced Labor and Child Labor in Supply Chains Act |

Products made with forced labor will be barred from Canada and companies could be fined up to $250,000 for violations. |

Pending in national legislature |

Jan 1 of the year following when the bill receives royal assent |

| European Supply Chain Act (Directive on Corporate Sustainability Due Diligence) |

|

Targets EU companies with 500+ employees and €150+ million in turnover and companies in high impact sectors with 250+ employees and a net worldwide turnover of €40+ million. |

Draft to be discussed in European Parliament, May 2023 |

Expected 2024 to 2025 |

| European Union |

Regulation on prohibiting products made with forced labor on the Union market |

Prohibits products made with forced labor from being sold/exported from the EU market. |

Proposed by the EC in Sep 2022 |

Expected 2024 to 2025 |

| Netherlands |

Responsible and Sustainable International Business Act |

Implements supply chain due diligence requirement for companies with €40+ million in turnover and 250+ employees (obligation for medium-sized companies in 2030. |

Pending in national legislature |

Likely 2024 |

| Belgium* |

Unnamed |

|

No action since 2021 |

n/a |

| Austria* |

Unnamed |

Introduces due diligence obligation for companies. |

No action since 2021 </tdstyle=”border: 1px solid black; border-collapse: collapse;”> |

n/a |

| Finland* |

Unnamed |

|

n/a |

n/a |

| UK* |

Modern Slavery (Amendment) Bill |

Update to the existing UK Modern Slavery Act from 2015. |

Under discussion |

n/a |

| UK |

Procurement Bill |

To exclude UK and overseas suppliers involved in modern slavery. |

Under discussion |

2023/2024 |

*These EU countries may be waiting for the EU to pass the Directive on Corporate Sustainability Due Diligence before passing their own supply chain laws.

In the United States, the Uyghur Forced Labor Prevention Act prohibits importing goods made in China’s Uyghur region, assuming that they were produced using forced labor. The Biden Administration recently added a ban on semiconductor chips produced in China for the same reason. Individual U.S. states have begun introducing their legislation with regards to human trafficking prevention.

Operational challenges to supply chain compliance

Collectively, global supply chain compliance laws seek to create greater transparency within supply networks and ensure that businesses worldwide take responsibility for ethical practices. But for large companies doing business across state and country lines, the myriad laws are impossible to monitor manually.

Supply chain visibility via digital mapping is essential for today’s complex global supply chain law compliance. With advances in artificial intelligence, companies can effortlessly monitor supply chain data and obtain real-time updates on the current state of supply chain compliance. Companies can anticipate potential legal issues and make better informed decisions. This transparency not only helps protect companies from violating supply chain laws, but it also ensures that suppliers are held accountable for their actions within the supply network. The impending EU supply chain law makes this level of visibility even more critical.

Cost savings and efficiency gains from using AI for supply chain compliance

With advancements in artificial intelligence and analytics, supply chain networks can become increasingly visible. This includes gaining insight into your suppliers’ labor practices, financial risk, labor unrest, cyber threats, your own logistics carbon footprint, and more.

Given the large amount of data to be collected and processed, AI is the only way to acquire this extensive visibility. AI can interpret vast amounts of complex information, building if-then scenarios, and creating risk forecasts. Armed with this extensive information, businesses are then better positioned to make informed decisions in a timely manner and keep their operations running at optimal performance.

Using AI, organizations can avoid expensive financial penalties and can create a more streamlined compliance workstream. Digital analysis can do the work that would normally require increased headcount. This, in turn, promotes higher productivity from existing staff members through improved collaboration and the ability to focus on larger goals. All this means that organizations can save money with compliance risk monitoring and evaluation.

Fines and penalties aren’t the only financial ramification for compliance. Public perception increasingly hinges on a company’s compliance profile, and that can either help or hurt a company’s value.

Achieving compliance, and being transparent about that journey, demonstrates to the public that a brand not only cares about following rules and regulations, but is serious about its brand values. Consumers crave brand transparency, and when they see brand compliance prominently displayed through media reports and social networks, it creates a positive image of the brand’s trustworthiness and dedication to sustainability practices. With so much trust in brand reputation at stake, brands must focus on meeting compliance standards as part of their overall brand management strategy.

Learn more about technology’s role in supply chain compliance

With more and more countries enacting supply chain laws to protect workers, protect the environment, and address unethical business operations, it is essential for companies to understand and keep up with global supply chain compliance. Supply chain managers must plan to ensure businesses compliance with existing and future regulations. By planning now instead of waiting until laws take effect, supply networks can not only avoid penalties, but also enhance their brand in the public eye.

To learn even more about universal supply chain law across the EU, download our latest white paper. Remember, being proactive when it comes to global supply chain compliance makes good business sense.