When it comes to managing supply chain tiers, we’ve found that our experiences with one client in one industry are transferable to others in other industries, particularly where one industry is further ahead than another. After decades of working closely with leading supply chain executives at global companies, we’ve found a handful of best practices that translate universally.

I’m going to tell you what three of them are, and you should adopt them at your company.

The three I’m focusing on are exemplified by one of our clients in the medical device industry, and I’ll share some of those details. These practices illustrate importance of what I call “ecosystem thinking” and why companies should look wherever possible to embed risk insights into existing platforms and to make those platforms smarter rather than creating new separate workflows for risk management.

Top tips for managing supply chain tiers

Everstream Analytics analyzes billions of data points every day, applying years of curated historical data to train our predictive computer models. Our multilingual teams work in the same regions as our clients’ supply chains. Companies that work with us turn supply chain risk into a competitive advantage by focusing on three key initiatives:

First, leading companies collect supply chain risk data. What’s supply chain data? That can include geographic risks like political unrest or hurricanes; cyber-attack risks for your suppliers and their suppliers; and financial insolvency risks. Standardized risk scores must be available across all supply chain functions so that teams can collaborate. Some of our clients share those risk scores with their suppliers and clients to synchronize their supply chain upstream and downstream.

Second, financial executives receive data about revenue at risk. This data is critical for developing accurate forecasts on goods and materials delivery. Accuracy here depends not only on understanding supplier risk, but the risk to your suppliers’ suppliers. A product-focused view of risk will illuminate materials and components sourcing, and score the risks at those locations.

Third, companies create visibility into their full sub-tier network because that is where most risk lies. Mapping an entire multi-tier supply chain network as an in-house project is tremendously difficult, maybe even impossible for some complex networks. But specialized companies employing big data and artificial intelligence are making that task easier every day. Leading companies are seeking out that technological expertise to map their entire sub-tier supplier base.

Medtronic is a great case study that encompasses all three of these best practices, and their challenges and solutions will resonate in any industry.

Explore supply chain tiers and risk analytics

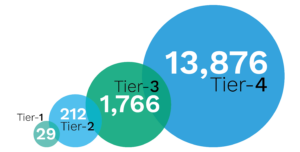

Everstream recently worked with a medical device manufacturing client to map the entire value stream for one specific product, and the results were astounding. Starting from Point A – a specific product manufactured at a specific location – we first analyzed their Tier-1 network, made up of 29 companies.

Stepping into the sub-tiers, Everstream’s process uncovered that based on those Tier-1 suppliers and the materials they sourced, Tier-2 widened to include 212 different suppliers across the globe. Moving to Tier-3, we discovered 1,766 different suppliers. Drilling down to Tier-4, we found a total of 13,876 different suppliers.

This client had strong relationships with their Tier-1 suppliers, but clearly it’s impossible to communicate closely with over 13,000 sub-tier suppliers. And the potential issues that could affect their production grow exponentially with each tier expansion.

Humans can’t physically track risk potential across 13,876 suppliers, but technology can. Risk analytics can be automated so that the right people receive the right alerts about the most important potential disruptions.

Humans also can’t manually uncover that vast number of sub-tier suppliers to even begin monitoring them for risk potential. But again, technology can. Everstream’s platform aggregates billions and billions of supply chain transactions and then cross-reference those with industry-specific reference data on manufacturer locations and products.

The platform then adds graph technology and entity resolution technology to sift through billions of transactions and pull out millions of individual suppliers, their facilities, and their connections to other companies.

Embed risk into existing platforms

Everstream combines that intelligence with data our clients already have, ultimately mapping a visual representation of their multi-tier supply chain. And because artificial intelligence and the humans who interpret the results are always learning, the data gets better with each cycle.

A human may not even know what changes to monitor and what questions to ask about those changes. But because a graph shows supplier interdependencies, changes will show up. Say a soda manufacturer suddenly switches from plastic to glass bottles – that will affect multiple industries that aren’t even in the Food and Beverage space.

When you have that much sub-tier visibility, admittedly you’re going to create a significant amount of noise. The more companies can connect their systems and automate, the easier it is to take noise out of the system and start automating more impactful decisions.

For example, think about hurricane season. Imagine if you preloaded your expectation in terms of your own finished goods inventory to increase during hurricane season so that you have more buffer. Or you could send that additional demand to your supply base that’s in that region that says during hurricane season we want six weeks or eight weeks instead of 30 days. Imagine that happening automatically based on your risk information coming in and building that buffer to manage that risk.

Staying dynamic for managing supply chain tiers

Ultimately, your company is either on the path or not on the path of applying a data science approach to supply chain visibility. Without big data, you cannot have a dynamic view of multi-tier suppliers.

A dynamic view of risk gives you the data and the insights to share internally and externally for partners to trust that what you say is actionable. If you integrate with the right platforms, the right type of insights and build trust in those insights, it’s a magical thing. We’ve seen that happen with our clients, and it has transformed their supply chains. Multi-tier visibility is just an enormous competitive advantage.

Get our “Risky Business” eBook to learn more about how technology tracks and rates supply chain risk