The world is watching. That’s why today’s companies are taking more responsibility than ever for their supply chains to ensure that they employ ethical practices. This is where the concept of “ESG” (Environmental, Social, and Governance) comes in. ESG provides a framework for organizations to evaluate the sustainability of their operations and assess how they impact people, planet, profits, and society.

That’s the “feel good” part of ESG, but there’s also a business argument to be made. The world’s largest trading economies are creating and enforcing ESG regulations, forcing global companies into compliance. And growing media and public attention focus on ESG practices, shunning brands that are found to be in violation of best practices.

Here is what ESG means within the context of supply chain management, why it matters, and examples of how technology can track risk, violations, and compliance with ESG standards.

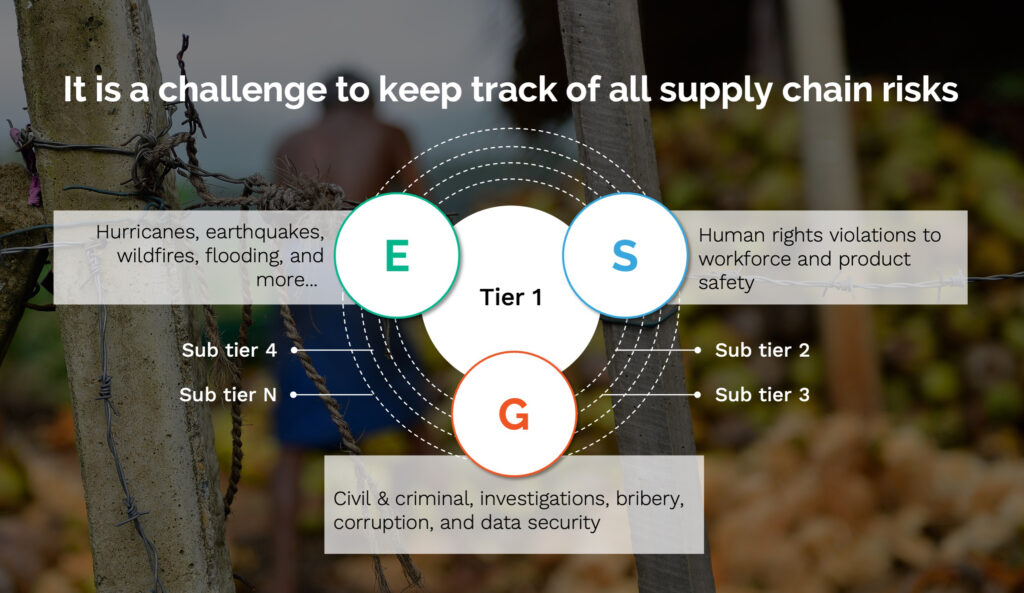

Figure 1: Supply chain ESG risks encompass human rights issues, but also key business operation activity.

Why ESG matters to supply chains

Managing for ESG has become an area of opportunity. By incorporating environmental, social and governance factors within their supply chains, companies are better able to identify areas of risk and take advantage before their competitors.

Today’s technology incorporating artificial intelligence (AI) can help a company assess the sustainability of its raw materials sourcing, production processes, and labor practices. This helps create a more transparent supply chain that is better positioned for positive outcomes for both stakeholders and the environment.

Technology can be used to track and monitor ESG compliance in several ways. For example, technology can be used to trace materials throughout their lifecycle, allowing companies to know where their materials came from, how they were made, and if ethical practices were followed along the way. AI can be used to calculate a supply chain’s entire carbon footprint, supporting any documentation and reporting efforts. And risk-management software can alert managers to business-critical issues before they damage a company’s operations or reputation.

Environmental: The “E” in ESG supply chain

The environmental part of ESG focuses on reducing the negative impacts of production and operations on the environment. This includes reducing energy consumption, waste management, greenhouse gas emissions, and related practices. Companies must openly report their environmental practices to remain transparent and prove compliance with ESG standards.

Monsanto is a highly visible example of a company that faced negative media attention due to non-compliant environmental practices. In 2020, Monsanto was exposed for failing to meet their own sustainability goals, and the company’s existing practices in fact had a detrimental effect on the environment. This led to boycott threats and negative media attention that damaged the company’s business reputation.

There are five ways that supply chain managers can support the “environmental” pillar of an ESG strategy.

Water management

All companies should take into consideration how their operations affect water supplies, especially manufacturing operations and locations based in high water risk areas. Efficient water management systems and water risk forecasting can help reduce water demand and waste production, ultimately leading to lower costs for businesses and improved environmental sustainability.

Greenhouse gas emissions

Companies should also strive to reduce their GHG (greenhouse gas) emissions by using renewable energy sources and limiting non-renewable resources, and partnering with suppliers and shippers who do the same. Watch for new sophisticated supply chain technology that can measure and document the carbon footprint of an entire supply chain, including sub-tier suppliers and shipping to the customer.

Energy efficiency

By adopting an energy-efficient approach to supply chain management, companies can reduce their carbon emissions and overall energy output. This can be achieved through the implementation of renewable technologies including solar panels, fuel cells, and wind turbines. Efficient lighting systems and heating/cooling systems can add to those savings.

Deforestation

Deforestation is one of the biggest contributors to climate change and companies should take steps to promote reforestation support whenever possible in a supply chain ESG strategy. Companies can also evaluate suppliers based on their sustainable forest management practices.

Circular economy

Instead of relying on new raw materials to produce goods, companies should strive to adopt a “circular economy” approach and seek out suppliers who do the same. This involves utilizing existing resources, such as recycled materials, to create products in a sustainable manner.

Social: The “S” in ESG supply chain

The social section of an ESG strategy measures a company’s commitment to ethical working standards and labor practices throughout its supply chain. This includes a quality of living wage, health and safety, gender equality, and freedom from forced labor. Companies are assessed based on their policies concerning all these areas, as well as their performance in implementing them.

For supply chain managers, this means looking for and supporting diversity and inclusion, fair working conditions, strong employee and community relations, and human rights within their organization and its global network of suppliers.

Automaker Hyundai’s connection to child labor at a sub-tier supplier is a recent example of how quickly a bad social practice can tarnish a brand. Unfortunately, there have been increasing instances of numerous companies being brought into the media spotlight due to labor violations or exploitation in their supply chain, with devastating effects on public opinion and corporate reputations.

To shore up the “social” pillar of an ESG strategy, look to these five operation areas.

Human rights

Labor conditions at your operation or that of your suppliers must include freedom of speech and association, protection from harassment or discrimination, and the right to form unions. Companies are increasingly being held responsible for the actions of their suppliers for compliance with global supply chain legislation in Germany, the U.S., Europe, and other major trading countries.

Working conditions

Poor working conditions can lead to exploitation of workers and negatively affect the reputation of an organization. Supply chain managers should ensure that all suppliers meet basic standards such as providing a safe workplace, fair wages, and reasonable working hours. Supply chain risk management software can uncover potential violations of labor laws and help managers take steps to ensure compliance.

Diversity and inclusion

Achieving greater diversity in the workforce begins with recruiting from a wider range of backgrounds. This can include minorities, individuals from lower-income communities, or those who previously faced work-related discrimination. It also means actively promoting policies and practices that are inclusive to all employees. This includes things like providing equal pay for equal work and making sure everyone has access to the same opportunities.

Community relations

Supply chain managers should strive to build relationships with local communities to create a positive impact on the environment. This can include supporting community initiatives, creating employment opportunities for locals, and minimizing any negative environmental impacts that may arise from the company’s operation – and documenting and sharing those practices with community members.

Employee relations

Maintaining good relationships between workers and management is essential to create a positive work environment. Supply chain managers can do this by encouraging open dialogue between employees and supervisors, promoting positive feedback, and offering training and development opportunities to ensure workers are equipped with the right skills.

Governance: The “G” in ESG supply chain

The third pillar of ESG requires companies to look inward to protect and optimize internal operations. Governance refers to a company’s own management practices, applying security, transparency, and ethical practices to risk management, cybersecurity, pay structures, and more.

Toshiba shareholders were enraged when company executives were found to have colluded with Japanese government officials to influence shareholder voting for new board members. Toshiba was further accused of trying to block certain shareholders from exercising their voting rights. After an internal investigation failed to assuage shareholder concerns, they successfully voted to remove the board members in question and to revamp the nomination process.

To avoid disruption from governance issues, both internally and with external partners, companies should focus on these five areas.

Risk management

Risk governance applies not just to your operations, but your entire supply network. This includes assessing supplier risk through all the sub tiers, including insolvencies, operational risk, labor unrest, and more. By understanding these various types of risks and taking measures to minimize them, a supply chain manager can ensure that their business runs smoothly with minimal disruptions.

Cybersecurity

With cybercrime on the rise, and increased digitization of operations, supply chain managers must take measures to ensure that their data and processes are as secure as possible. This means having proper cybersecurity measures in place to protect customer data and the company’s operations from potential cyber threats, and monitoring partners and suppliers for their risk of breaches (which can create entry to connected companies).

Reporting and disclosure

Supply chain managers must ensure that they are transparent and open about their supplier connections, logistics operations, particularly with sustainability issues. This means providing accurate reports to investors and stakeholders on supply chain performance, policies, and environmental impact.

Board structure

A good board structure should focus on creating a diverse and inclusive environment, where all members have a voice. It should also support all operations of the company, including supply chain management, in meeting sustainability goals and objectives.

Executive compensation

Companies must ensure that the total pay of their executives reflects not only the performance of the company, but also that it meets ethical standards and promotes responsible behavior.

Supply chain ESG’s lasting value

Supply chain risk management technology can provide the backbone of a strong ESG policy. From tracking the energy consumption of suppliers to examining the sourcing of materials to tracing labor practices throughout the supply chain, AI-powered insights and supply chain mapping can alert managers to risk levels before violations develop.

Ultimately, companies that embrace ESG principles within their supply chain management are better equipped to mitigate risk and create sustainable value for all stakeholders involved. Creating operations that are ethical, responsible, and sustainable supports a more transparent ecosystem that creates lasting value.

Watch our webinar to learn more about technology for supply chain ESG