Supply chain visibility is the ability of stakeholders to access real-time data related to the location, movement, and state of products within the supply chain. It is an essential element of modern supply chains, connecting different stages from raw material sourcing to product delivery. This visibility is a key part of risk management, as it enables the early identification and mitigation of potential disruptions, helping businesses manage uncertainties more effectively.

Supply chain visibility is related to supply chain transparency, but the two terms are not interchangeable. Visibility refers to data that an organization uses internally to monitor, manager and optimize its supply chains. Transparency refers to supply chain data that is shared with customers, regulators, interested third parties, and other stakeholders. While companies strive to maximize the data they have on their own supply chains, for reasons of commercial sensitivity they will only share a subset of that data externally.

Why Visibility Matters

With globalization, supply chains have become increasingly complex and intertwined. This was starkly demonstrated in 2025. This year brought tariff turbulence; the U.S. government shutdown; export controls on rare earth minerals and magnets from China; port strikes in Europe, to name a few disruptions.

Supply chain turmoil, coupled with the growing consumer demand for responsible sourcing, has amplified the need for supply chain visibility. Moreover, the need to comply with regulations and industry standards necessitates clear visibility into operations to ensure adherence and demonstrate accountability.

Supply chain visibility offers several benefits, including:

- Enhanced risk management

- Early identification of potential risks, enabling proactive measures to prevent disruptions

- Empowered decision-making, facilitating improved operational control.

- Stronger supplier relationships through open communication and collaboration, allowing for better supplier performance evaluation and more reliable sourcing

Supply chain visibility underpins supply chain transparency, which can help strengthen brand reputation. Consumers tend to trust businesses that are transparent about their operations, including their sourcing and manufacturing processes. and some customers insist on it. By showcasing ethical and sustainable practices in the sourcing and manufacturing operations, businesses can build a positive brand image.

Figure 1: Supply chain visibility may be difficult, but offers significant benefits that protect brand reputation.

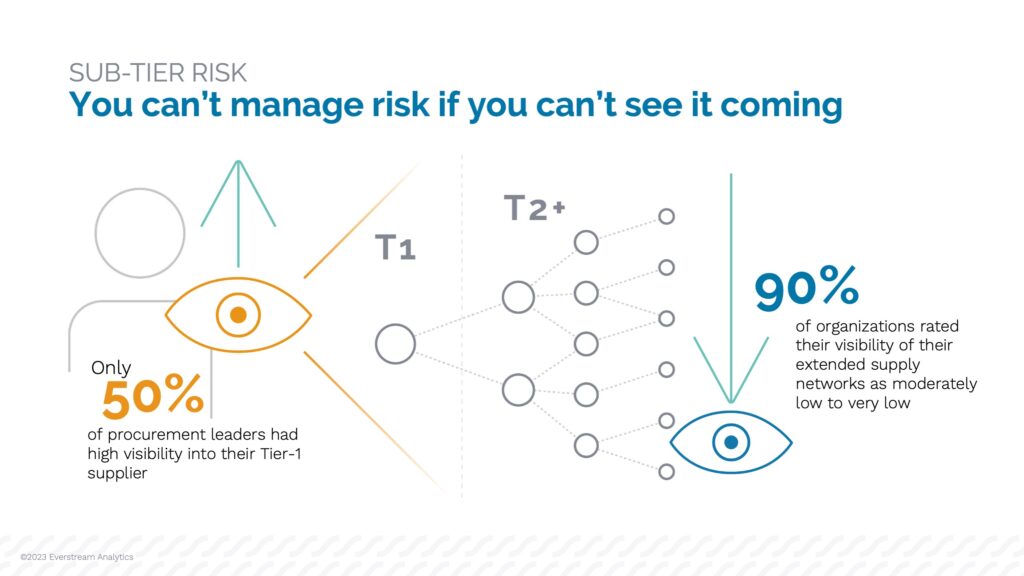

Why Visibility is Hard

Despite its benefits, achieving supply chain visibility is not without its challenges. Collecting and managing data across various stages of the supply chain can be a daunting task. Supplier resistance and reluctance have historically posed obstacles, as not all parties may be willing to share their data. Lastly, the costs and resource constraints associated with implementing visibility measures can be a deterrent for some businesses.

Technology has a key role to play in overcoming these challenges. The power of advanced digital platforms and AI can accelerate, streamline, and automate many supply chain visibility tasks. That includes the acquisition and integration of supply chain visibility data as well as the analysis of that data to support operational and strategic decision-making.