The future of supply chains will heavily depend on an increase in carbon efficiencies and lowered emissions, so it’s likely that your company is beginning to collect data on carbon outputs to get ahead of the game on compliance and brand reputation. The next step is to plug that data in to a workable supply chain carbon footprint calculator.

Collecting carbon data is only half of the game. Real value comes from using advanced analytics to convert that data into carbon intensity metrics and identify areas for targeted action. Understanding the carbon intensity of each step of your supply chain will allow you to make clear, educated decisions about the least carbon-emitting choices, thereby increasing your overall carbon efficiency and lowering key environmental risks.

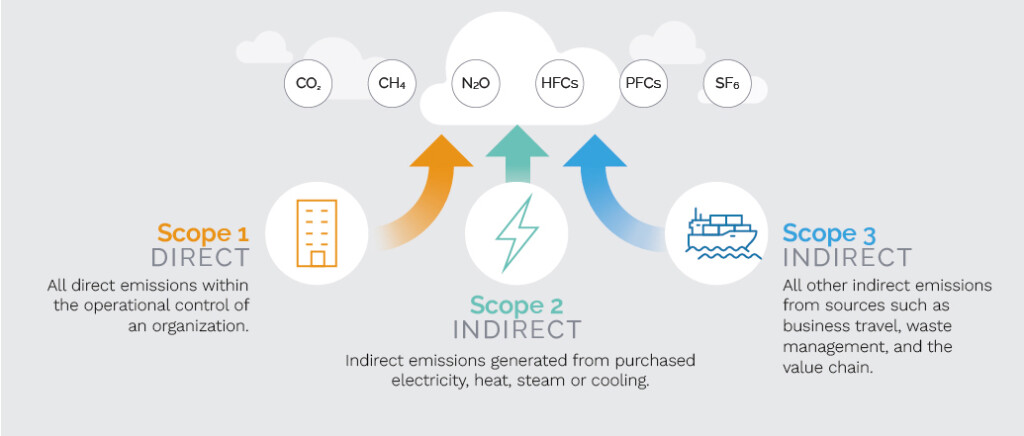

Figure 1: Under Scope 3, companies are responsible for understanding, reporting, and mitigating their supply chain carbon footprint across their entire value chains.

Collect the right supply chain carbon footprint calculator data

Carbon intensity measures greenhouse gas output created per unit of activity, such as transportation or manufacturing. Since carbon intensity is calculated by considering specific activities which can be adjusted within a supply chain, it is a more accurate and useful assessment than raw, overall carbon output. For example, supply chain managers may change shipping methods after calculating the carbon intensity of their current air freight arrangements, or look to find manufacturing efficiencies within the product-making process. Leveraging AI-powered analytics to evaluate the carbon intensity of an activity, plus human expertise to make critical, informed changes, companies can lower their overall carbon output.

Start by creating your own supply chain carbon footprint calculator, tailored to your supply chain’s specific needs.

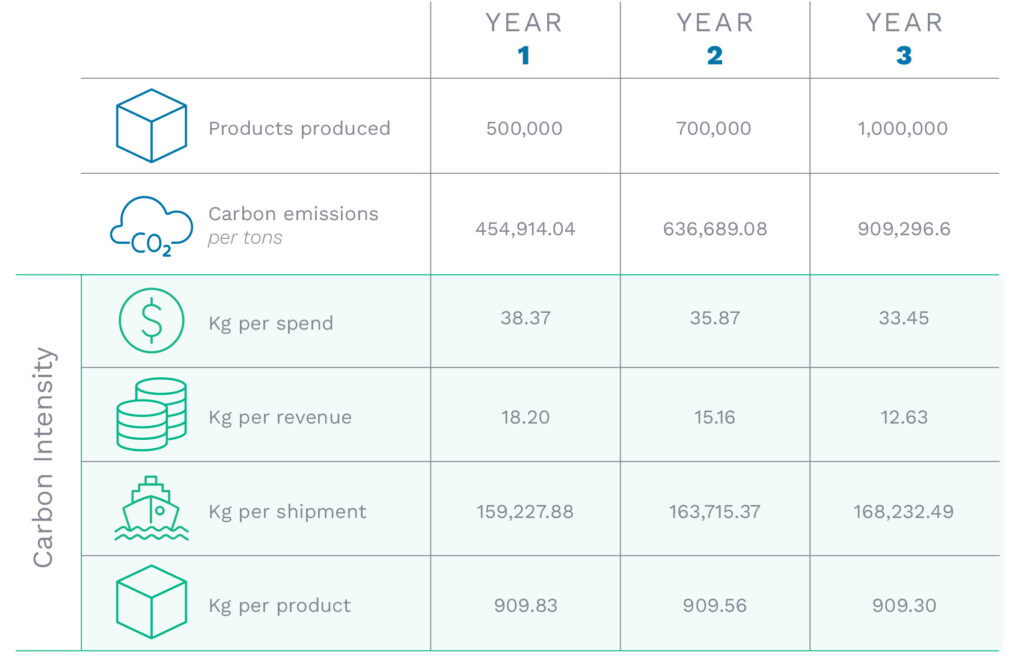

Figure 2: As a company growth doubles, its supply chain carbon footprint doesn’t necessarily have to mirror that growth rate. Carbon intensity can be managed to stay the same or decrease, in some cases.

Creating your supply chain carbon footprint calculator

Every supply chain carbon footprint calculator will be different, customized to fit the needs and particularities of each company’s industry, products, and processes. When mapping your supply chain and deciding which segments to tackle first, consider these five key questions:

- Which segments of your supply chain generate the most carbon emissions?

Starting with supply chain activities that are high emitters could be the path to a big win in carbon reduction. For example, maybe your operation frequently ships materials between production facilities, and can reduce that frequency by using larger container sizes. The key is to use technology to gather and analyze relevant transportation data, instead of manually collecting information or jumping to conclusions. Then, armed with this information, you can fully understand the impact each segment of your supply chain is having on your overall carbon emissions and select the quick wins.

- Are there any potential alternatives to your current processes?

Start with what you can change within your processes. Could you source energy differently or switch to another method of transportation? Is it time to replace old, inefficient machinery with newer, fuel-conscious technology? Take a look at your current processes to see if anything can be updated and optimized with carbon in mind.

While it may seem like a steep initial investment to change your current processes, the decrease in carbon emissions will pay off over time as new carbon legislations come into play and public awareness rises. Gaining a first-mover advantage by switching to lower-carbon options earlier can also improve your company’s reputation with highly environmentally aware Gen Z and millennial consumers.

- What regulations is your company subject to worldwide?

Environmental and regulatory risks can go hand-in-hand, with a raft of new legislations beginning to pass around the world aimed at tackling carbon emissions and setting net-zero targets. These legislations, while similar in intent, often vary depending on the country and industry, making keeping up with the rules a risk category in and of itself. Instead of trying to operate with different environmental policies throughout your supply chain, which is costly and time-consuming to implement correctly, consider following the strictest country’s policies throughout your entire global operations. This ensures your company is always compliant, and will compel you to make key decisions earlier, leading to greater carbon efficiencies.

- What are your operational KPI priorities?

Again, this supply chain carbon footprint calculator needs to be specific to your company’s needs. What will work for one company won’t necessary work for the next, even if they’re competitors within the same industry. Identify your priorities within your key KPIs, whether that’s company reputation, the bottom line, regulatory compliance, or more, and align supply chain decisions accordingly.

- What can be changed internally vs. influencing change externally?

While a company may oversee a supply chain end-to-end, it doesn’t always have control of the individual segments. For example, shipping and freight is often outsourced to a logistics supplier, and therefore not always able to be adjusted. Making internal changes is the first step to increasing carbon efficiencies. Then, looking for ways to influence supplier behavior and processes, such as contract clauses, incentives, or education, will come next.

Once the supply chain management team has applied these questions to current processes, companies can begin to adjust their supply chains for carbon efficiency. However, don’t just set and then forget about these new policies. Continuously monitoring and adjusting these changes as a part of your overall supply chain risk management will be key to identifying environmental wins, or spotting when a different decision needs to be made.

Using your supply chain footprint calculator

With an increase in new carbon regulations and legislations set to pass around the world, businesses can no longer ignore their carbon outputs. Similarly, keeping an eye on carbon production by tracking overall outputs without pairing it with actionable changes to supply chains is no longer good enough.

Take advantage of AI-powered analytics to fully understand the carbon intensity throughout your supply chain and adjust your processes accordingly. Doing so sooner rather than later will not only give you a first-mover advantage, but also give you the understanding to make decisions that support KPIs and business goals, keeping your company’s operational priorities in mind.

Increased carbon efficiency doesn’t have to be an impossible task. In fact, “better for the environment” can be better for business.

Learn more business applications in our carbon intensity white paper

Heather Kosztowny is the Director of Data Science for Everstream Analytics, leading development and implementation of transportation modeling and optimization insights. Her 15 years of experience in data analytics and modeling have focused on logistics issues and carbon emissions evaluations and insights.