Supply chain logistics risk is complex, varied, and constantly changing. Businesses are constantly aiming to improve their logistical efficiency, trying to find places to cut costs and time, all while maintaining and exceeding customer expectations. But efficiency is just one piece of the supply chain puzzle. It is not even the most important one. In fact, efficiency may introduce significant logistics risk to your business during a disruptive event. Instead of making efficiency your core methodology, focus on logistical resilience to build agile and durable supply chains.

Why resilience is better for logistics risk

Supply chain logistics managers have traditionally focused on efficiency, attempting to reduce time and, therefore, costs, with customer satisfaction dictating metrics. As a result, there have been great advances in logistical efficiency. This is evidenced by businesses around the world adopting Toyota’s revolutionary just-in-time inventory approach. But these kinds of approaches don’t provide any bulwark against disruptions, creating efficient but potentially very fragile supply networks.

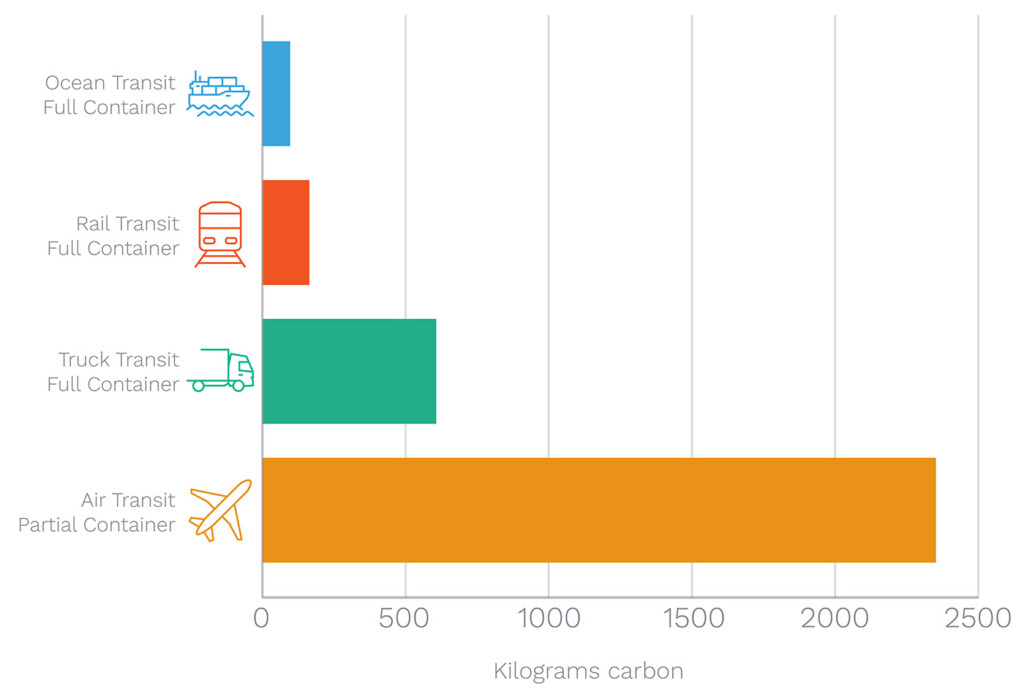

A resilience-based approach to logistics may increase shipping times and costs in the short term. Nonetheless, it ultimately grants businesses better long-term flexibility and profits. Resilient logistics operations are better prepared in the face of major disruptions. Plus, they are better equipped to deal with changing regulations on carbon emissions. Focusing on resilience, therefore, ensures that efficiencies include adaptability. This gives companies the ability to withstand short-term disruptions and turn rapidly and smoothly to plan B, plan C, or even plan D to mitigate longer disruptions. As a result, investing in resilience is an investment into business continuity in the face of an ever-shifting supply chain landscape.

This move to resilience marks a larger shift within the supply chain ecosystem. Companies now work to be the most reliable suppliers instead of only focusing on speed. Of course, delivering quickly is still an important metric. However, customers are increasingly choosing suppliers that can fulfill their contracts reliably, meeting a promised delivery date even in the face of disruptions. By choosing to focus on resilience, businesses can offer realistic estimates for shipping products, providing customers with a sense of security and trust.

How resilience works for logistics risk

Resilience in supply chain logistics can take many forms and is dependent on real-time, ongoing data. Without a complete understanding of the full landscape of a supply chain and the events or disruptions happening within it, logistics managers run the risk of depending on alternative plans that may not appropriately address current issues.

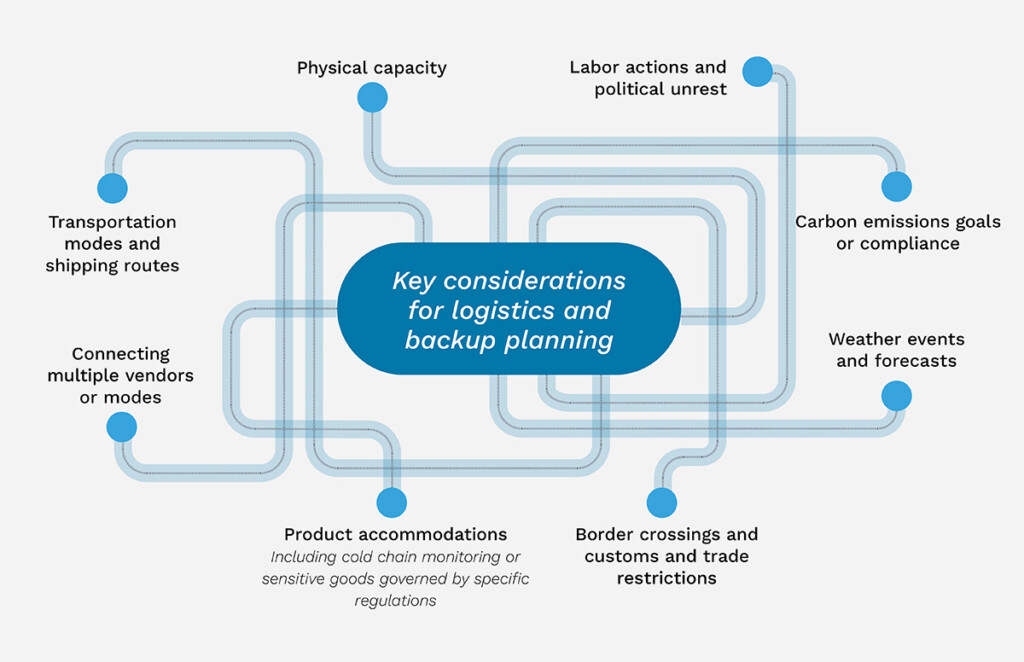

There is a wide range of considerations to evaluate in logistics planning and backup planning, which may include:

- Physical capacity

- Transportation modes and shipping routes

- Connecting multiple vendors or modes

- Product accommodations, including cold chain monitoring or sensitive goods governed by specific regulations

- Border crossings and customs and trade restrictions

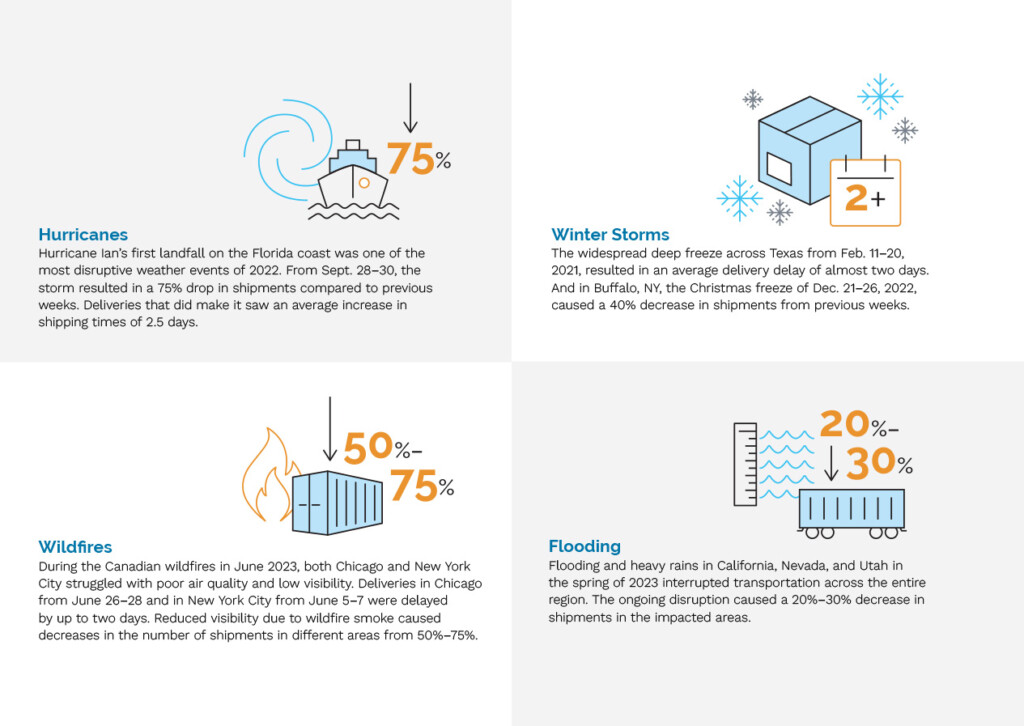

- Weather events and forecasts

- Carbon emissions goals or compliance

- Labor actions and political unrest

- Cybersecurity

- and many more

Figure 1: Logistics risk can arise from multiple operational areas, requiring comprehensive supply chain risk planning.

The impossibility of manually monitoring logistics risk

Manually monitoring the “what ifs” and plan Bs for an ever-increasing number of variables is no longer possible. Today, it’s crucial to leverage advanced analytics to monitor, collect, and analyze the data from all of these variables. Coupled with human oversight from experienced data scientists who understand the nuances within supply chains and ongoing risks, AI takes the guesswork out of logistics risk management.

Pairing technological analysis and human oversight is ultimately what will give companies the ability to move quickly and make effective logistical decisions. Data analysis alone, for example, may not account for nuances within a business’s operations. Conversely, supply chain managers alone may miss crucial details. Combining the two provides the assurance that all details have been considered and that good logistical decisions can be made with confidence.

Supply chains can be thrown off course as easily as a storm can cause logistical disasters. But, with real-time monitoring and analysis directed by supply chain managers who understand the situation at hand, logistical nightmares can become operational success stories.