The interconnected nature of supply chains is simultaneously extremely beneficial and burdensome to businesses. Sourcing materials or placing production around the world offers companies a lower cost basis from which to do their business. However, the successful production and transportation of their products depends greatly on how well the different parts of their supply chain work together.

Staying on top of short-term risk assessments is key to staying alert to emerging issues and making effective mitigation decisions. This is especially true within the world of supply chain logistics. Logistics already relies on a delicate balance of transportation options, good weather, and conducive geopolitical situations. Therefore, it’s no surprise that the nature of logistics risk assessments are changing as quickly as the logistics risk landscape is changing.

Businesses must understand the key emerging risks within their supply chain logistics by running accurate and functional risk assessments. Armed with the relevant data, supply chain logistics managers can make the necessary adjustments for supply chain success.

What to consider in a logistics risk assessment

Acute logistics risk assessments aren’t a one and done kind of task. Rapid changes occur within the supply chain ecosystem. Therefore, point-in-time snapshots of the state of your supply chain will only last so long. Having a continuous view into your acute logistics risks means that your company will be able to make decisions on an ad hoc basis, as issues are developing. Of course, it can be helpful to keep an eye on historic data for future reference. However, if you’re waiting for the next scheduled review, your risk mitigation actions will likely be too late.

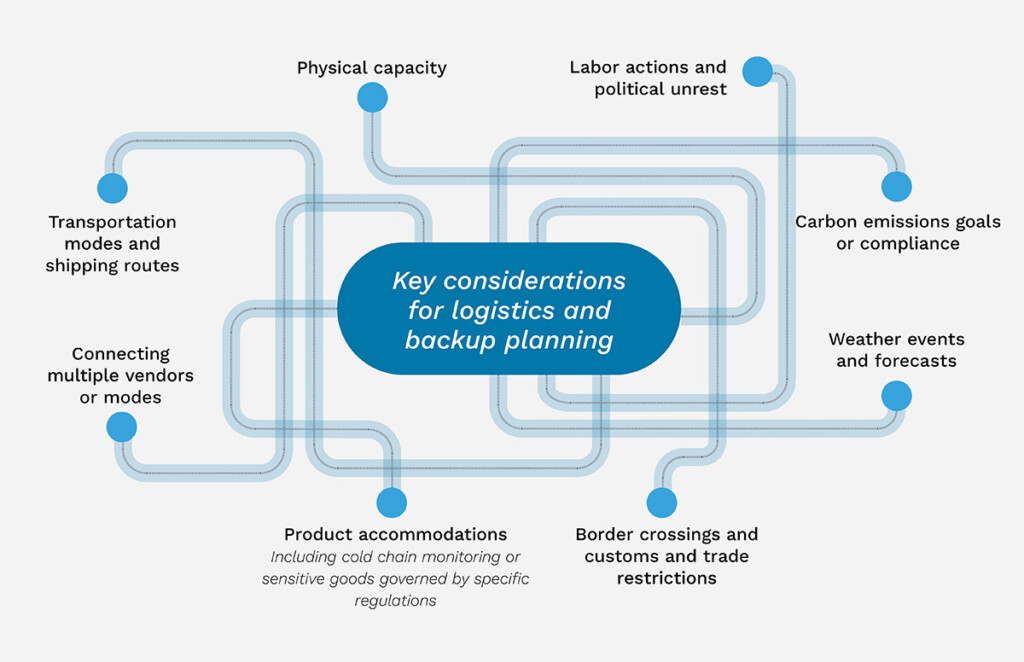

Figure 1: Multiple elements go into today’s acute logistics risk assessments.

Furthermore, not all risk data is created equal. It’s worth taking the time to set up your logistics risk assessments properly, with relevant global data from a variety of trusted sources. Relying on one source alone is risky. It may mean that you’re missing out on key information that you can base your next actions on. And, similarly, regularly checking that you’re getting the logistics data you need to make informed decisions goes a long way to creating an effective risk management system.

Unfortunately, there’s no cut-and-paste logistics risk assessment that will work for every company. However, we now have advanced tools to more accurately evaluate logistics risk. AI-powered predictive analytics are more likely to accurately highlight emerging issues. Ideally, you should combine continuous monitoring, advanced analysis of ongoing risk data, and historic trends. This gives businesses the best possible information for logistic risk assessments.