Logistics is one of the most complex pieces in the supply chain puzzle. Sure, logistics seems straightforward, just get a load of products from point A to point B, but it’s rarely that simple. There are many risks inherent to logistics, including climate events and geopolitical shifts.

Many companies already know that proactive, informed decision making is key to smoothing over any logistical disruption. However, with this many uncertainties at play, it can be difficult to know what to tackle first.

Don’t waste time trying to reinvent the logistics wheel; shift your perspective on logistics instead. Focusing on resilience first, as opposed to pure efficiency, and understanding what exactly is in your company’s control can go a long way to minimizing logistical risk within your supply chain.

Resilience vs. efficiency

What does logistical success look like to your business? Many operations have prioritized streamlined “just in time” efficiencies, but ironically that structure makes operations more brittle in the face of disruption. Scrambling for alternatives requires intense resources and cost. When logistics operations can’t flex in response to disruption, that compromises on-time delivery and customer satisfaction.

Shifting your primary focus to resilience instead invites operations to find a better balance. You can operate efficiently while retaining the resilience needed to successfully function in volatile supply chain situations.

LEARN HOW TO BALANCE LOGISTICS EFFICIENCY AND RESILIENCE IN OUR NEW WHITE PAPER: DOWNLOAD NOW

There are many different ways to increase logistical resilience. For example, in today’s growing push for lower carbon emissions, companies that heavily depend on air freight might consider switching to lower carbon modes of transport and using risk management to keep delivery times reliable. Businesses that start making this switch sooner rather than later will be impacted less by the various carbon regulations going into effect over the next decade. Or companies may decide to store extra stock in key locations, in case of an extreme weather or geopolitical event that disrupts normal shipping flows. More dramatic and long-term changes may include changing manufacturing locations, though this won’t always be possible.

Resilience in supply chain logistics may present upfront costs, especially during the transition period. However, the benefits will multiply when your company is able to operate normally in the face of damaging disruptions.

Realistic alternatives in logistics

In theory, it would be nice to instantly mitigate every risk identified within a supply chain. However, in practice, businesses just can’t control every aspect of their supply chain. Risk management in logistics can only go so far; supply chain managers may make key decisions, but they can’t captain the ship that’s carrying their products personally. One of the keys to minimizing risk within supply chain logistics is focusing on what your company does control. Then businesses can put strategies in place that are data-driven and adaptable to changing circumstances.

For example, certain materials or supplies may only be produced in certain regions. Or tariffs and trade regulations may make sourcing from other locations very difficult. Changing geopolitical situations aren’t in a company’s control, and strikes and other industrial action may leave businesses with little recourse as these disputes are settled.

Therefore, companies must have contingency plans in place that make sense within the context of shifting circumstances. While managers often turn to historic solutions, there’s no guarantee of a same, successful outcome. Plan Bs based solely on tribal knowledge or a hunch may cost your company dearly if they don’t take into account new trends, regulations, or situations. Logistics managers should understand what their best alternative is in each segment of their logistics, based on continuous and relevant data.

Using a combination of active risk data monitoring and historic trends in logistics, supply chain managers can decide the best alternatives based on the circumstances at hand. Re-routing cargo, upping the amount of stored products, and understanding potential substitute suppliers are just a few of the actions logistics managers can take to minimize disruptions within a supply chain.

Predictive analysis

For best results, ensure that your logistics managers are making the best use of their time. The days of manually scanning through data and piecing together an accurate interpretation are long gone. Plus, historical trend data can’t reliably predict future events or reactions when weather or geopolitical situations are outside norms.

Instead, using predictive analytics powered by Artificial Intelligence allows your managers to have an ongoing view into any logistical risk and make decisions accordingly. This also means that your business has access to global supply chain data, highlighting issues that may not appear relevant until it’s too late.

Additionally, sourcing global risk data will allow you to respond to events that you may have never dealt with before. For example, if an uncharacteristic weather event hits your supply chain, logistics managers can see how other supply chains handled similar situations. AI can even suggest best practices in the face of these unforeseen events. Coupled with human oversight, managing logistical risk can operate as smoothly as a well-oiled machine.

Businesses should begin discussing how to balance resilience and efficiency within their supply chains, especially for something as vulnerable to disruption as logistics. Using AI and predictive analytics in conjunction with the expertise of logistics managers will be key to making quick and effective decisions in the face of severe interruptions. These short- and long-term changes will shape your company’s ability to weather future logistical storms.

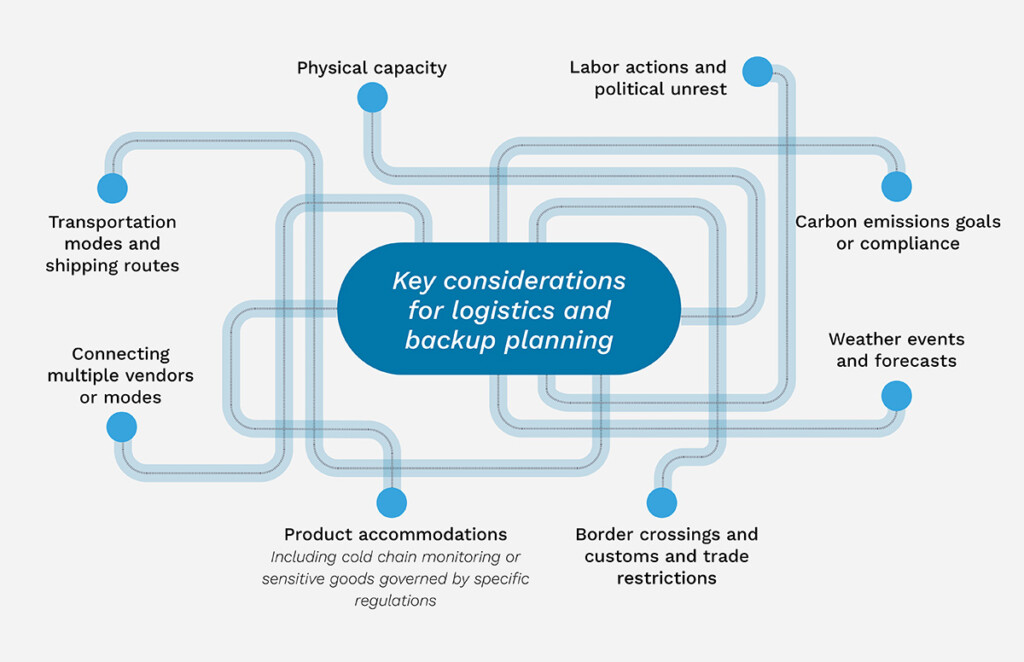

Figure 1: Risk management in logistics requires a shift from prioritizing efficiency to building resilience in key areas.

Risk management in logistics is shifting. An early focus on resilience allows for agility later on, so don’t discount the changes your company can be making now to improve supply chain outcomes over the next decade.

LEARN HOW TO BALANCE LOGISTICS EFFICIENCY AND RESILIENCE IN OUR NEW WHITE PAPER: DOWNLOAD NOW