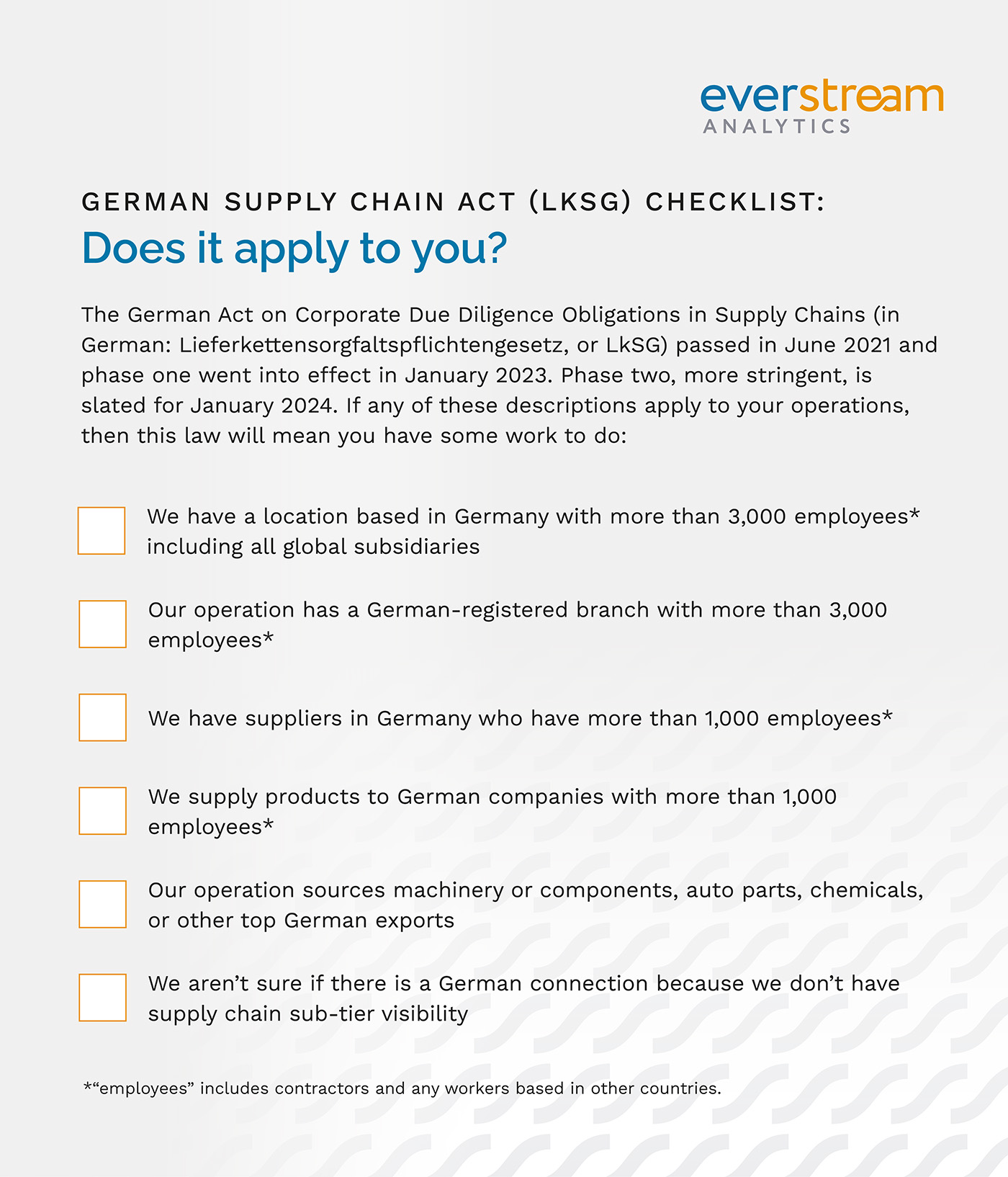

Now that it’s January 2023, the first phase of the German supply chain act (known in Germany as LkSG) goes into effect. This only matters to you if your operations are affected. Scrutiny on supply chain ESG violations is high and potential fines are steep, but even out-of-scope companies will feel the impact of these big changes to the world’s 4th largest economy.

Also important: The German act is a precursor to pending European Union regulations, which will be stricter and more widespread. Now is the time to prepare for both by determining whether the German act affects your supply chain (in phase one or phase two), what it covers, and how to respond.

Essentially, any company doing business with the world’s third biggest exporter (so, everyone) will face supply chain network changes relating to forced labor or environmental risks. For example, an auto parts distributor based in California that purchases parts from German manufacturers doesn’t fall under German law itself, but could face disruption as their German suppliers adjust their operations for compliance, or are found in violation.

How the German supply chain act (LkSG) will affect your operations

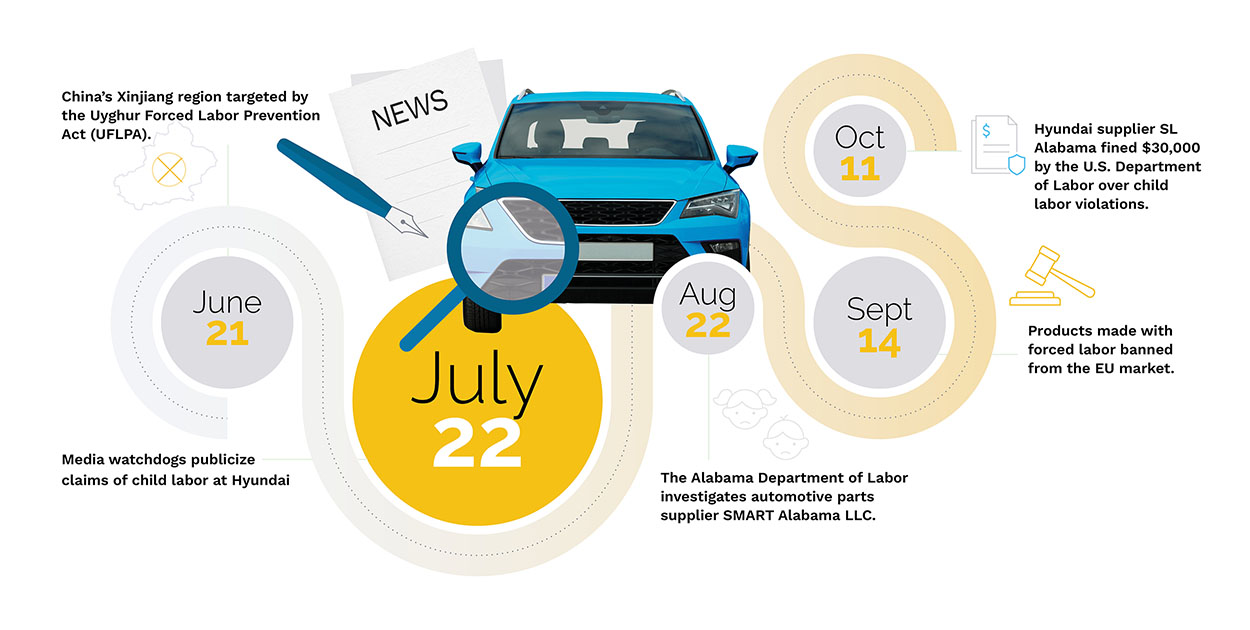

The German supply chain act will cascade across the globe, but in a different way than the U.S. Uyghur Forced Labor Protection Act (UFLPA). Operations that aren’t in scope to fall under the German act could feel the impact when large firms pass on their own due diligence obligations. And any company with a German-based connection in their supply chain could feel disruption as those operations restructure to comply with the act.

As your suppliers and distributors work to comply, your risk increases in several ways.

More paperwork and visibility

If you are selling to German-based companies, you face potential compliance requirements from German firms requesting LkSG governance documentation, monitoring processes, and defined codes of conduct.

German companies are now adapting their own LkSG-focused processes to identify risk areas in human rights, environmental damage, and other environmental, social, and governance (ESG) focus areas. Even if you already have full supply chain visibility with low ESG risks, you may be asked for ongoing documentation on supply chain issues including forced labor, child labor, discrimination, unethical employment, freedom of association violations, unsafe working conditions, and environmental degradation

And with the EU supply chain law and others on the way, the need for supply chain risk management automation to achieve greater transparency is greater than ever.

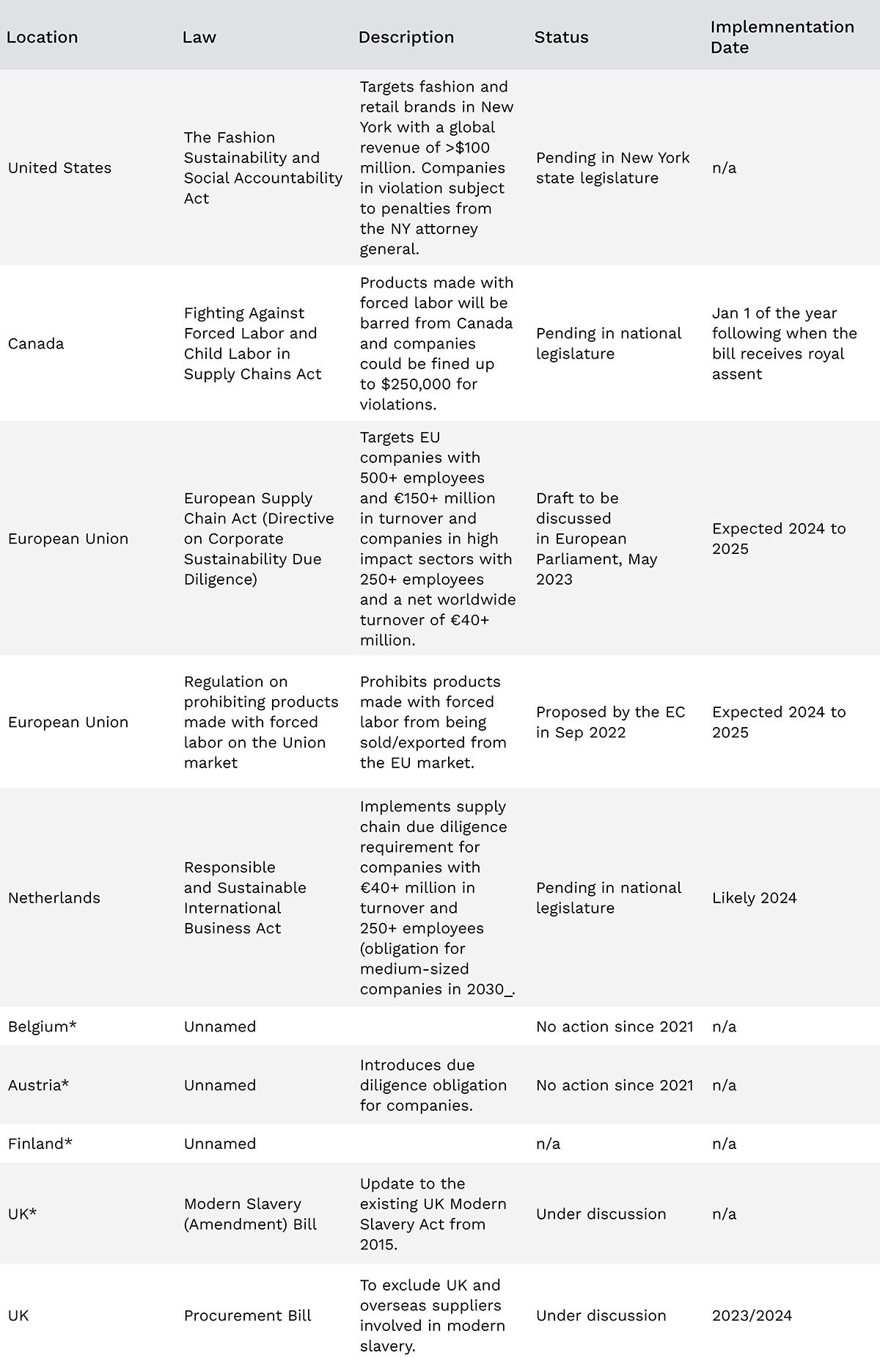

Table 1: Global supply chain laws on the horizon

*These EU countries may be waiting for the EU to pass the Directive on Corporate Sustainability Due Diligence before passing their own supply chain laws.

Financial stress

Non-compliance costs are significant. Companies face penalties and fines of up to $8 million or 2% of annual revenues and exclusion from public tenders for up to three years. That doesn’t include the risk of brand damage and resulting revenue loss.

A high risk of the German supply chain act violation carries a corresponding high risk of financial disruption, including insolvency. Insolvency risk buried in a supply chain sub tier can remain invisible for months, then leave companies scrambling to fill gaps.

Material shortages and delays

As German-based firms restructure their supply chains, they could face supply gaps, quality changes, or price increases that will pass to their customers. Some of these disruptions could have major impact – for example, in formulations supplied to medications manufacturers.

Expect competition to rise for suppliers that are already in compliance. That could create product delays or price increases. Companies must rate the risk now to avoid issues downstream.

How digital supply chain mapping can help mitigate LkSG risk

At minimum, all companies should identify potential risk from the German supply chain act. Digital mapping creates a supply network visualization that is easy to monitor for many kinds of risk, and can lay the groundwork for evaluating impact from other supply chain legislation.

- Identify your supply chain Tier 1 sustainability risks

- Start working on identifying your Tier 2, and further sub-tier supplier risks, which will be needed for upcoming regulations

- Rate the level of risk at each supplier for potential disruptions

- Shift plans to mitigate the risk as necessary

- Document assessment and plans for reporting purposes

If your operation falls within scope of the German supply chain act, compliance will require more detailed action after digitally mapping the supply chain:

- Establish a risk management system

- Define where compliance responsibility sits within the company

- Issue a policy statement

- Perform ongoing risk analyses using a digital supply chain map

- Establish preventive measures within the company and with direct suppliers

- Execute due diligence prevention measures for known risks at indirect suppliers

- Take remedial measures if necessary

- Establish a complaints procedure

- Document and report

Digital mapping supports several compliance steps, including a risk management plan, ongoing risk analysis, supplier due diligence, documentation, and reporting.

Prepare now to preserve resources

EU lawmakers will meet again in May 2023 to discuss pending supply chain regulations. Because proposed European legislation is stricter and more widespread than German laws, far more companies will feel the impact both directly and indirectly.

Everstream advises preparing now to save both time and money by planning ahead. If you need any help to get started immediately, reach out to our experts.

Watch our webinar to see how to identify forced labor risk in your supply chain