Have you ever wondered what keeps the wheels of commerce turning smoothly even when the world seems to be filled with unpredictability? The answer lies within a practice known as Supply Chain Risk Management (SCRM). Picture this: a carefully constructed tower of blocks—each block representing a stage in your product’s journey from raw material to a customer’s hands. Now, what happens if one block wobbles? SCRM is the art of predicting that wobble and reinforcing the tower before it can topple.

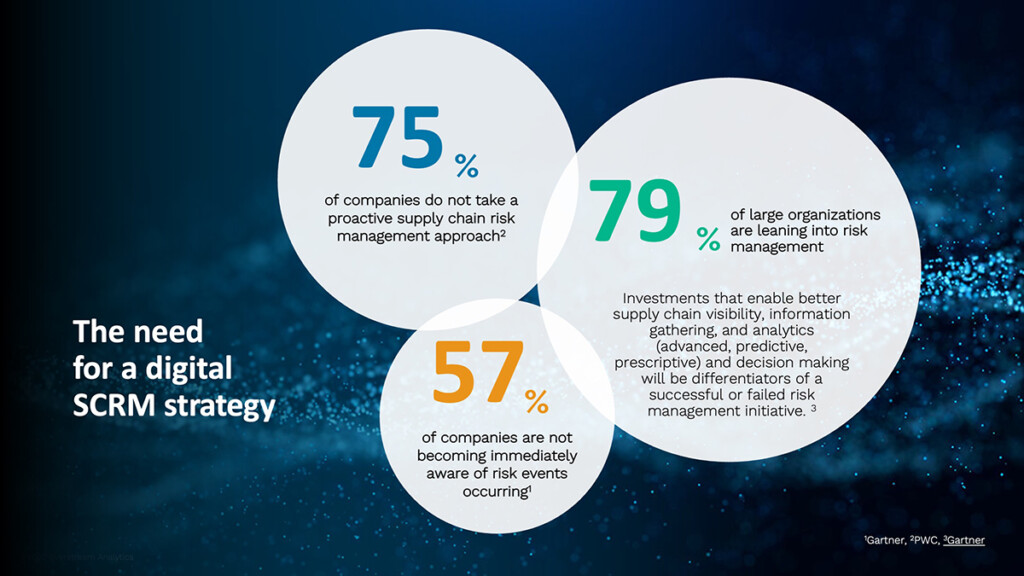

Figure 1: A majority of large organizations are leaning into SCRM to improve supply chain visibility, information gathering, and analytics.

The Anatomy of SCRM

SCRM is essentially the proactive approach to foreseeing, assessing, and mitigating risks to your supply chain. It involves identifying potential disruptions, be they natural disasters, economic fluctuations, or technological failures, and planning strategic responses. It’s like a game of chess where each piece is a component of your supply chain; you must anticipate your opponent’s moves and have your counter-moves ready.

HOW TO APPLY SUPPLY CHAIN RISK MANAGEMENT TO YOUR OPERATION: FREE REPORT

What is SCRM: Identifying risks

What keeps you awake at night? As a supply chain manager, it should be the thought of unaccounted risks. The first step in SCRM is identifying these risks. Every supplier, every mode of transport, and every product has its vulnerabilities. The key is to put on your detective hat and uncover these potential threats before they manifest.

What is SCRM: Assessing risks

Once identified, risks must be evaluated. Not all risks are created equal—some can cause minor delays, while others can shut down your operations for months. The goal here is to categorize these risks based on their potential impact and the likelihood of their occurrence.

What is SCRM: Mitigating risks

Now comes the heart of SCRM—mitigation. After laying the groundwork, you need a robust strategy to either dodge these risks or at least soften the blow. It’s like preparing for a storm; if it’s coming, you’ll want to board up the windows and stock up on essentials.

What is SCRM: Monitoring and adapting

Finally, managing risk is not a set-and-forget task. The market shifts, suppliers come and go, technology evolves. Effective SCRM involves constant monitoring and the flexibility to adapt. Are you ready to change course if the winds shift?

Technology: The compass of SCRM

Picture a seasoned sailor using the stars to navigate the vast ocean; that’s the role technology plays in the sea of SCRM. It’s the compass that points supply chain managers in the right direction, allowing them to chart a course through the tumultuous waters of market trends and disruptions.

Technology like predictive analytics acts as a lighthouse, warning ships of the rocks ahead even when the fog of uncertainty looms large. With tools such as AI and machine learning, we can not only predict the wobble in our tower of blocks but brace it with the precision of a skilled architect. And in the digital age, isn’t it a comfort to know that an algorithm can watch over your supply chain just as a lighthouse keeper watches over the bay? Can your current technological toolkit stand the test of turbulent seas? Let’s keep that question in mind as we dive into the specifics of SCRM.

Tips for effective SCRM implementation

Now that you have a basic understanding of what SCRM is, let’s explore some tips for implementing it effectively within your organization.

- Build a strong team: Implementing an effective SCRM requires collaboration and communication among different departments and stakeholders. Build a team with a diverse skill set to cover all aspects of SCRM.

- Conduct regular risk assessments: Risks are constantly evolving, so it’s crucial to regularly assess your supply chain for potential disruptions. This will help you identify new risks and adapt your mitigation strategies accordingly.

- Utilize technology: As mentioned earlier, technology plays a crucial role in SCRM. Invest in tools and software that can help you identify, assess, and mitigate risks more efficiently.

- Foster relationships with suppliers: A strong relationship with suppliers can often be the key to mitigating potential supply chain disruptions. Communicate openly and collaborate closely with your suppliers to build trust and ensure transparency.

- Plan for the worst-case scenario: While it’s important to have contingency plans for potential risks, it’s also crucial to plan for worst-case scenarios. This will help you be better prepared and able to mitigate any major disruptions that may occur.

- Communicate and educate: As a supply chain manager, it’s your responsibility to communicate and educate all stakeholders about SCRM and its importance. This will help build a culture of risk awareness and preparedness within the organization.

Remember, effective SCRM is an ongoing process that requires constant monitoring, adaptability, and collaboration. By implementing these tips and continuously assessing and improving your strategy, you’ll be better equipped to handle any potential disruptions in your supply chain. Keep building those blocks strong!

To sum up, SCRM is a crucial aspect of supply chain management that involves identifying, assessing, and mitigating risks to your supply chain. By following the SCRM blueprint and utilizing technology, fostering relationships with suppliers, and continuously improving your strategy, you can build a strong and resilient supply chain that can weather any storm. But it’s an ongoing process that requires constant vigilance and collaboration among all stakeholders. So keep those counter-moves ready, stay agile, and always be prepared to adapt. After all, in the world of supply chain managemeint, the only constant is change.

HOW TO APPLY SUPPLY CHAIN RISK MANAGEMENT TO YOUR OPERATION: FREE REPORT