August’s severe flooding in Slovenia hit the automotive industry hard, making it the most impactful supply chain event of 2023. But the outside world didn’t recognize the level of disruption until months after the fact. Meanwhile, automotive companies with sophisticated supply chain risk management (SCRM) systems knew immediately where the risks were and what to do about it. Here we explore the ramifications of a key event from our 2023 Year in Review.

Flooding impact on the global automotive supply chain

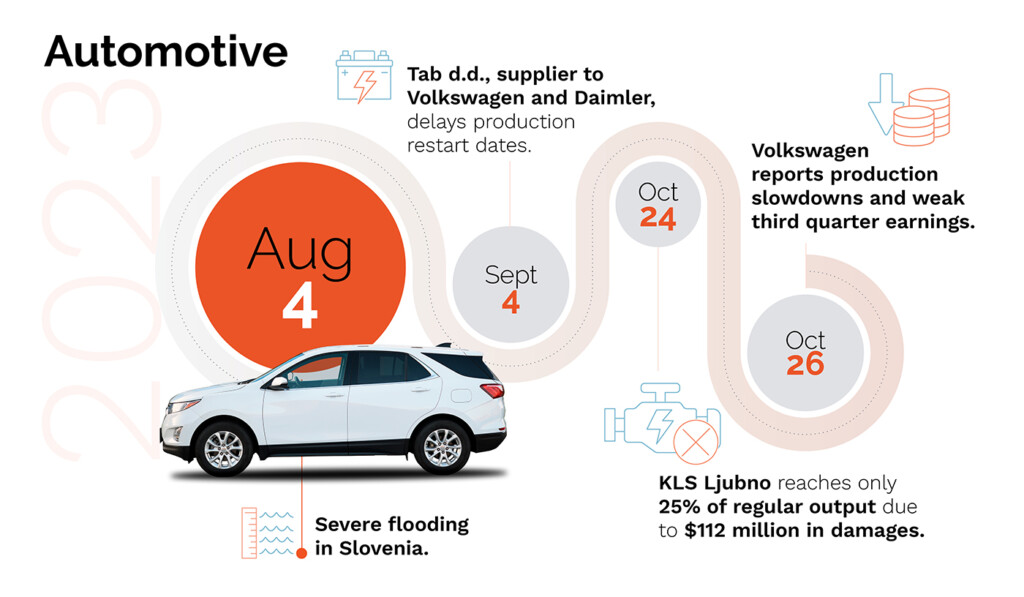

In August 2023, Slovenia was hit with devastating floods, cutting off several towns and causing a staggering $7.6 billion in damages. The auto industry felt the ripples immediately due to the country’s integral role in the supply chain – every car produced in Europe includes at least one component from Slovenia.

By September, the impacts were beginning to be seen outside the automotive supply chain. Tab d.d., a key battery supplier to the likes of Volkswagen, Volvo, and Daimler, publicly announced production delays in two plants. As the waters receded, the flood’s wider effects came into focus, revealing disruptions to thousands of small and medium-sized companies.

By October, the full scale of the catastrophe became evident. KLS Ljubno, a manufacturer of shaft ring and starter ring gear, was at just 25% of its regular output, and full production isn’t expected until March 2024. This caused engine part shortages across multiple auto manufacturers, highlighting the fragility of the global automotive supply chain.

Figure 1: Flooding in Slovenia caused $7.6 billion in damage to infrastructure and manufacturing, with significant impact to global automotive supply chains.

Days later, Volkswagen announced production slowdowns, leading to weaker-than-expected 3rd quarter earnings. A sobering number of 150,000 planned cars could not be built due to the parts shortages stemming from the Slovenia floods.

Managing global automotive supply chain crises

So, how could companies have best managed this massive disruption? Sophisticated SCRM systems can alert supply chain managers early to rising risk, creating more agility and time to respond.

Supply chain risk management offers insights into the various risks throughout a company’s supply chain layers at direct suppliers and beyond. With this visibility, managers receive alerts about relevant risks early. Adding risk scoring helps clarify how likely these risks are to develop into real problems.

Managers using SCRM to assess supplier risk would have known that Slovenia was in a flood-prone region, and they could have chosen backup suppliers to rely on in case of flooding. Planning for risk in advance creates an agile supply chain that can pivot quickly in the face of sudden disruption. Automotive manufacturers could have activated alternative suppliers, mitigated potential production delays, and avoided shutdowns.

Implementing supply chain risk management

The Slovenia flooding event serves as a stark reminder of the need for greater insight throughout within the increasingly interconnected global automotive supply chain. Today, the adoption of digital SCRM tools isn’t just a nice-to-have — it’s an essential tool for risk mitigation, ensuring that when the next disaster strikes, businesses are prepared, resilient, and agile.

So, if risk management is the key to a more resilient supply chain, how can businesses effectively implement it?

Leveraging technology

In the digital age, data is king. Advanced analytics and Artificial Intelligence (AI) can process vast amounts of data to provide real-time insights into your supply chain. Imagine being alerted to a potential disruption before it even happens? That’s the power of predictive analytics.

Collaboration and communication

A siloed approach is a recipe for disaster in supply chain management. Establishing strong communication channels with suppliers can enable early detection of potential risks. Remember, a chain is only as strong as its weakest link.

Regular auditing

Regular auditing of your suppliers and their suppliers can help identify potential vulnerabilities. Think of it like a doctor’s check-up, but for your supply chain. Regular check-ups can detect potential risks before they escalate into serious issues.

Driving future success

The impacts of the Slovenia flooding on the global automotive supply chain underscored the importance of preparedness, resilience, and agility in today’s interconnected world. Supply chain risk management, enabled by technology and strategic planning, offers a supportive path forward. As we navigate the uncertainties of a rapidly changing world, digital risk management can provide a safety net, ensuring businesses continue to thrive amidst global challenges.