COVID-induced disruptions may be over, but they were a preview of the shortages and risks ahead for the food and beverage supply chain. Planners are now focused on long- and short-term disruptions from climate change. Historical weather patterns and the usual seasonal planning have gone by the wayside now that extreme weather events are growing in number and intensity.

From soaring prices of olive oil to CO2 shortages to failed sugar crops, extreme weather is shifting long-term commodity outlooks, draining manufacturing resources, and interrupting transportation. To adapt, F&B supply chain professionals will need to understand the weakening points in their supply networks.

F&B operations already lead many other industries in logistics and planning. Now, it’s time to incorporate advanced climate modeling and end-to-end supply chain visualization to build resilient supply chains that can weather future storms.

Food and beverage supply chains face stormy transportation

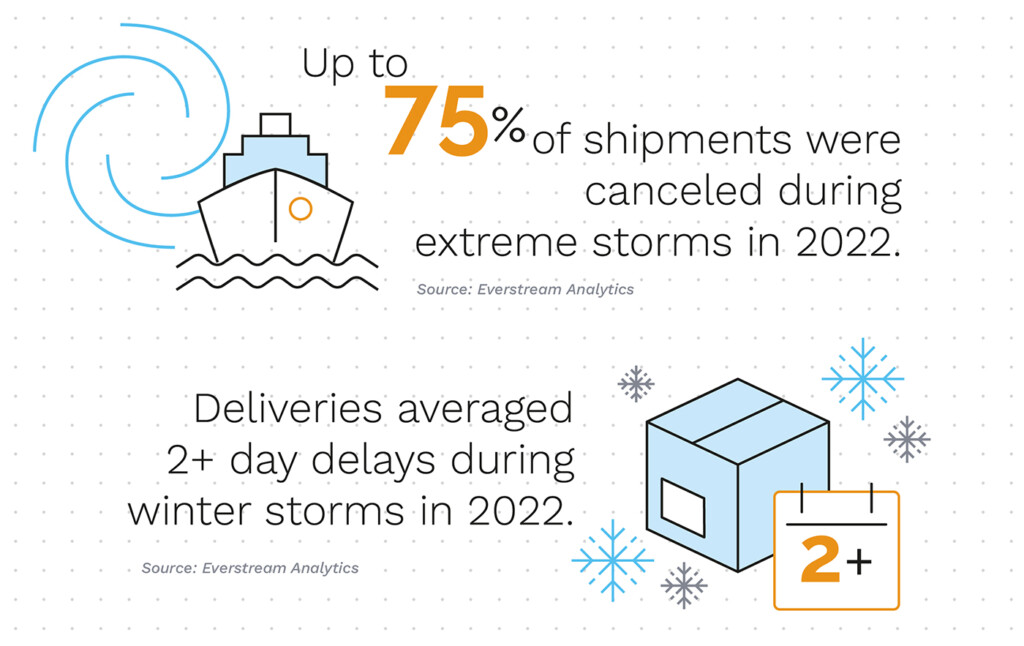

Figure 1: Everstream’s research found that extreme weather costs companies significantly in delays and cancelled shipments.

Drought, water shortages, record heat, and unusually strong storms all contribute to disruptions in transportation, and this changing weather demands new ways of thinking when it comes to logistics.

The transitional seasons of spring and autumn now bring major temperature swings and storms that would usually occur in mid-summer or winter. When logistics fail to account for these changing weather models, shipments can be delayed, disrupted, or even completely destroyed.

For example, extreme heat in desert routes has caused shipments to melt even when protected by refrigerated trucks, causing product loss and quality control issues. Instead of planning these shipments as usual, logistics teams must now model temperature shifts carefully, incorporating predictive analytics to evaluate and respond to long-term risk. For example, during the hottest months, a company may opt to ship refrigerated items at night.

Similarly, widespread regional drought impacts major navigational waterways like the Mississippi River, Rhine River, and Panama Canal. With lower rainfall levels, feeder waterways dry up, and river levels drop. This impacts barge shipments, potentially delaying deliveries or driving up delivery costs.

Network mapping coupled with applied meteorology creates insights to make transportation planning an efficient process, as opposed to an educated guess. Advanced weather modeling provides detailed information on temperature extremes, incoming storms, and other relevant climate changes that could impact a specific operation.

Short-term scarcities in the food and beverage supply chain

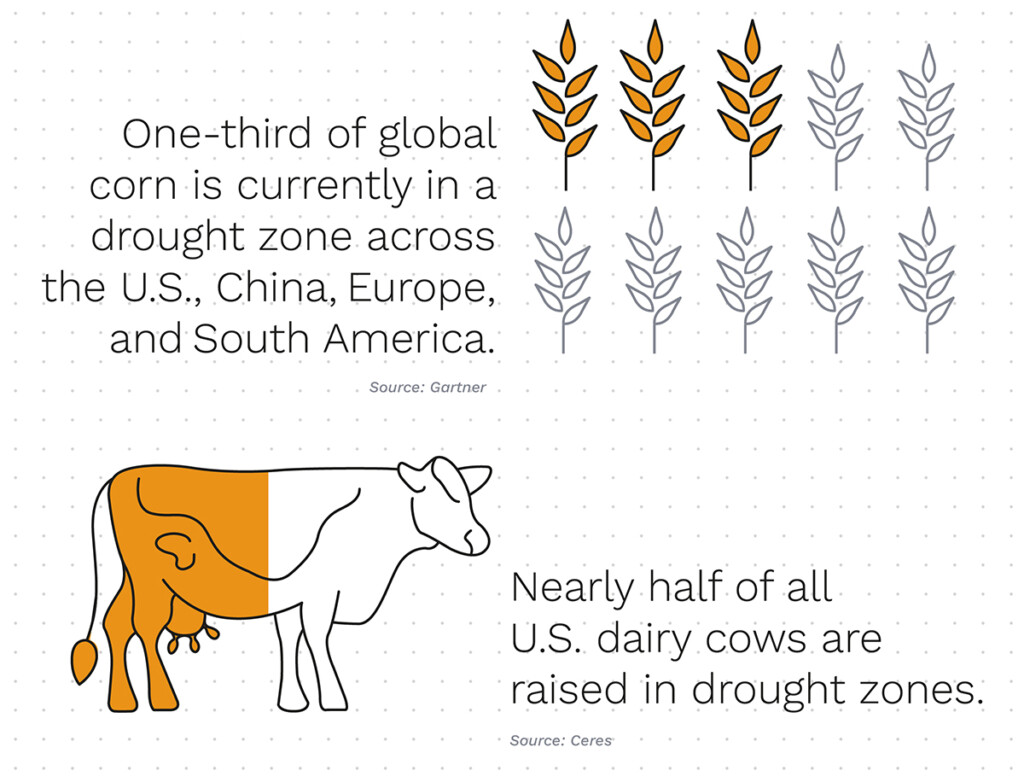

Figure 2: Food and beverage supply chains are suffering from drought-related shortages in grains, dairy, and other critical commodities.

Climate change is no longer just an environmental issue but one that can seriously affect a food company’s bottom line. Bad weather leads to bad crop outcomes. Olives, chili peppers, mustard, and rice are just some of many examples of recent crop failures due to severe drought or heat, causing prices to triple for consumers and manufacturers alike.

Rather than standing by and waiting for harvest results, planners can now access advanced weather modeling that shares commodities outlooks weeks earlier than traditional modeling so that supply chain managers have early warning of looming crop scarcities.

With these insights, companies can put contracts into place now to ensure consistent supply in the case of a shortage or switch suppliers in the face of disruptions, providing a first-mover advantage.

Long-term food and beverage supply chain strategies

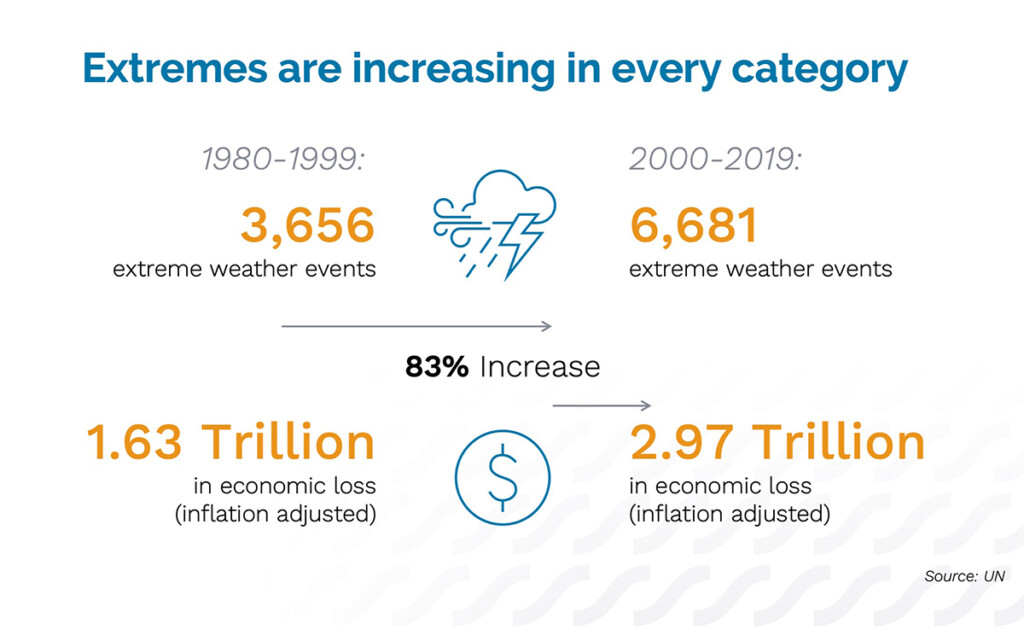

Figure 3: The food and beverage supply chain is poised to be hit hard by the era of extreme weather.

Crop shortages may not be new, but the amount of acreage for agricultural products affected by heat risk continues to grow. The next few years will be key for making decisions that will affect F&B operations for decades.

Companies that source crops from drought-affected areas, such as almonds or wheat, may need to find new production regions sooner rather than later. Long-term climate forecasting is already showing how dramatically heat and drought will increase in specific geographic locations.

With AI-assisted climate forecasting, F&B managers can use weather modeling to understand potential crop outcomes each year in order to effectively mitigate any looming risks. And for the longer term, businesses can look at the potential effects increased heat will have on key resources and products for years to come.

Network mapping that visualizes an end-to-end supply chain, combined with advanced analytics and AI to monitor and highlight risks, supports making efficient, educated decisions about forecasting, planning, sourcing, manufacturing, logistics, and site locations.

Now is the time to think about the next 10, 20, 30 years. Food and Beverage companies are already greatly affected by these ongoing problems, and they won’t be going away any time soon. Set your company up for supply chain success by taking action now.

Compliance in food and beverage supply chains

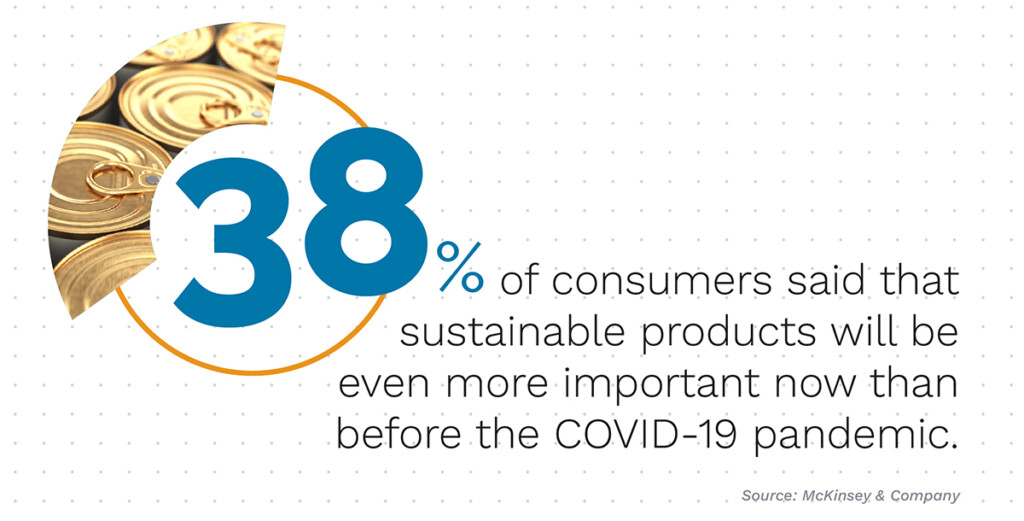

Figure 4: Consumers increasing seek out sustainable food and beverage products.

The global environment is changing, and not just climate-wise. New environmental, social, and governance legislation is coming into force around the world. Companies that are able to adapt quickly to these regulations and to consider the long-term strategic benefits of compliance may find that these legislations may help more than hurt. Non-compliance is simply no longer an option—between the hefty fines and the damage to reputation, no company wants to be caught breaking key ESG legislations such as the Uyghur Forced Labor Protection Act.

Having a long-term view of the environment and climate change, in particular, will help F&B companies make the right decisions when it comes to future raw material sourcing. And it could also prevent some costly fines down the line. ESG legislation may seem like a burdensome responsibility, but it can also be a business opportunity. Strike while the iron’s hot and make key changes before your competitors do to benefit from streamlined, agile supply chains, the decreased threat of fines, an increase in positive reputation, and a happier bottom line.

AI and supply chain mapping can help companies avoid these and other ESG issues as part of good business and also leverage that as a competitive edge. A supply chain risk-management platform with multiple layers can offer insights into one type of risk or a million—whatever your operation prioritizes—making it easy to build sustainability monitoring right into your corporate goals and profits.

Think about the last supply chain materials shortage you managed. If you had four months’ advance notice about it, what would you have done differently? How about if you had five years’ notice? Network mapping, climate forecasting, and risk analytics buy you that time, allowing you to better prepare for difficulties. Don’t get caught by surprise—get your supply chain ready for any disruptive event, rain or shine.