As beneficial as an efficient supply chain is, efficiency cannot be the sole focus. Today’s rapidly changing marketplace, customer expectations and demands, and other external forces that can even include the weather or natural disasters require organizations to become highly agile and adaptive. Efficiency does not inevitably lead to responsiveness.

We define a responsive supply chain as one that has flexibility to evolve with the expected and to react quickly to the unexpected. Others say a responsive supply chain is “one that is sensitive to meeting customer requirements.” ATM Marketplace says this: “Responsiveness can be defined as the ability of the supply chain to respond purposefully and within an appropriate timeframe to customer requests or changes in the marketplace.”

While the precise definitions may vary, it is clear that responsiveness is tied to change and time. Change happens, and now more than ever, it seems to happen all the time. How quickly companies can react to that change makes all of the difference in how well they can meet demand and expectations.

Efficiency is critical because out-of-control costs and wasted resources spell disaster, but efficiency is only of value if the supply chain can respond to what customers value at that moment. Companies that find the balance between the two elements is challenging but not impossible.

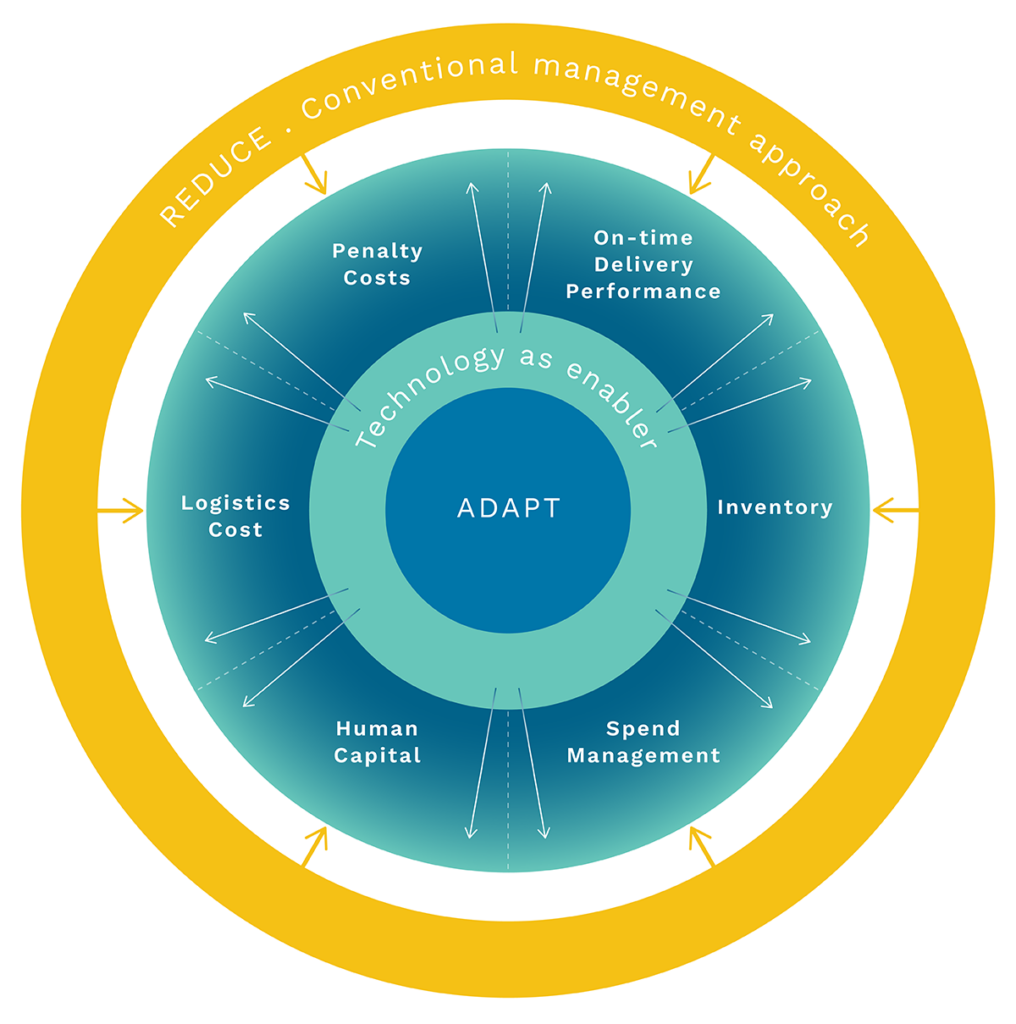

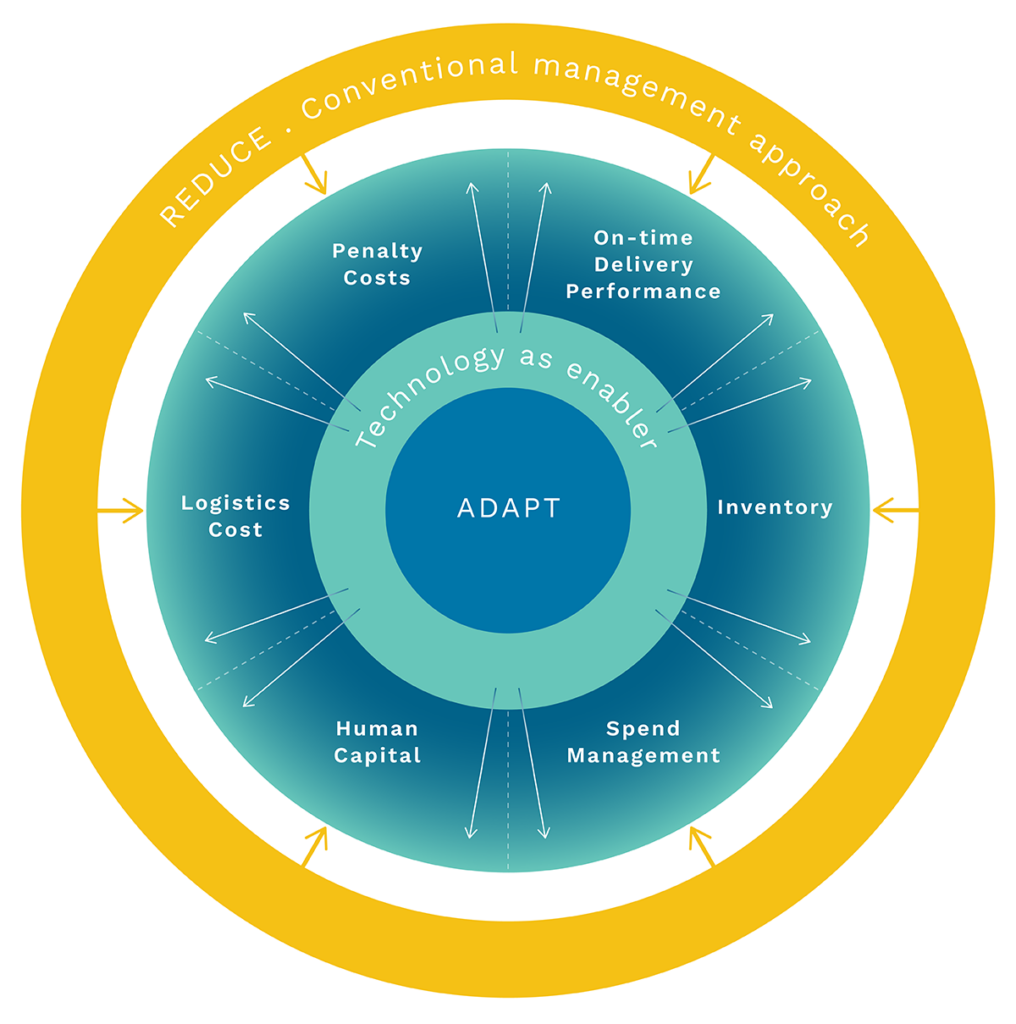

Technology is the foundation for an efficient and responsive supply chain

Companies need access to data in order to make smarter decisions about how they manage production, inventory, locations, and transportation. Unfortunately, data is often dispersed across multiple systems that sit in siloed business units. Without transparency and system integrations, leaders will have a difficult time establishing and enforcing efficient or responsive processes, much less an efficient or responsive supply chain.

Taking transportation as an example, many organizations rely on outdated data and manual efforts to plan and schedule shipments. Getting products to the customer connects everything prior to what comes next in the supply chain. Any delay in transportation not only prevents the shipper from operating efficiently or responsively, but it also impacts how well the rest of the supply chain can do the same.

The importance of transportation risk management software

To be efficient and profitable, as well as responsive to customer demands, companies need technology. There is simply too much valuable data out there from different sources that must be gathered and analyzed to rely on manual tactics, static spreadsheets, or disconnected systems.

Inbound Logistics says, “The technology that exists today plays a huge role in strengthening SCM [supply chain management] […] Technology enables companies to eliminate laborious manual intervention and speeds up decision-making. Arguably, technology-driven SCMs play a large part in helping companies to gain competitive advantage.”

If you aren’t taking advantage of technology to manage transportation as well as detect risks to shipments that can cause delays, you are likely wasting resource time (inefficient) and unable to meet your on-time in-full (OTIF) commitments (unresponsive).

Efficient and responsive supply chains foresee risk

There are multiple elements to ensuring a shipment makes it to its intended destination on time with the expected shipment. One of those elements is risks outside of the company’s immediate control, such as weather.

Forbes reported on statistics compiled by the U.S. Department of Transportation that focus on the impact of weather on supply chain shipments, saying carriers lose nearly 33 billion vehicle hours due to weather-related congestion, nearly 12% of total estimated truck delay is due to weather, and the estimated cost of weather-related delay to trucking companies ranges from $2.2 billion to $3.5 billion dollars annually.

As much damage bad weather can do, there are other risks to shipments. Those may include extreme temperatures that can compromise product quality, social hazards such as protests and criminal activity, natural disasters, and infrastructure outages. Any one of these issues can increase costs that impact efficiency and reduce responsiveness.

Suppliers need software that uses cognitive technology to detect risks to open shipments up to a week or more before tender so companies have time to make adjustments before those risks have a chance to impact efficiency or responsiveness. This advanced technology is capable of doing what humans simply cannot do – rapidly scanning every shipment to consider account origin, destination, pickup time, and projected arrival time to then simulating the shipment’s lifecycle with forecasted conditions.

Going a step further, the software scores each shipment to give leaders an instant read on those risks so they can focus resources on the highest risk issues for the greatest efficiency. Everstream offers a solution that does just that, in addition to flagging the number of miles each shipment will face those hazards. All data is displayed on a dashboard, as well as integrated with a company’s TMS system.

Everstream Analytics take efficient and responsive supply chains even further

Everstream allows its users to visualize exactly where the risks lie and their potential impacts, sortable by lane, market, or facility to quickly see how these threats may impact them and their customers. The data is robust, shareable, and highly accurate, enabling companies to be more responsive in how they respond to impending risks and customers who may be affected.

When leaders have access to real-time data early in the planning process, they are able to more confidently schedule each shipment and set the proper customer expectations. Schedules can be adjusted, as well as transportation mode, lane, or equipment to ensure the shipment gets to its destination as efficiently as possible. The software detects and analyzes risks that many of which would most likely have been missed using manual efforts, allowing companies to be more efficient and proactive in how it responds to those risks so it can meet customer demands.

Responsiveness does not have to come at the price of efficiency, or vice versa. Companies can have both if they use the right technology to empower them.