It’s hot out there

It’s no secret that our climate is changing. Every year, we see statistics that show just how much. This spring, the World Meteorological Organization (WMO) released yet another report highlighting the impact of climate change:

- 2019 was the second warmest year on record

- 2015-2019 are the five warmest years on record

- 2010-2019 is the warmest decade on record

- Each successive decade has been warmer than any preceding decade since 1850

- A new annual global temperature record is likely in the next five years

The impact of these changes can be catastrophic:

- Total economic losses from flooding in the U.S. in 2019 were estimated at $20 billion

- Tropical cyclone activity increased, with 72 tropical cyclones in the Northern Hemisphere in 2019

- Tropical cyclone intensity increased

- Wildfire activity increased globally

- The frequency and duration of heatwaves increased across several countries

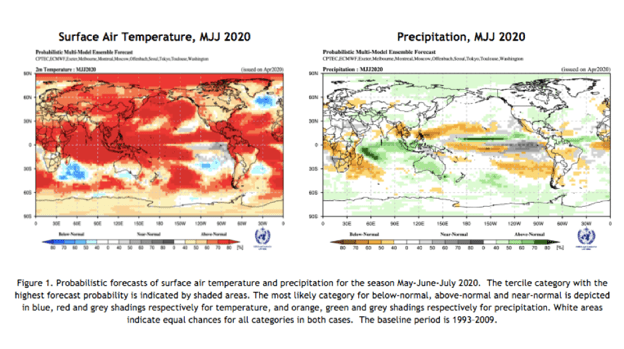

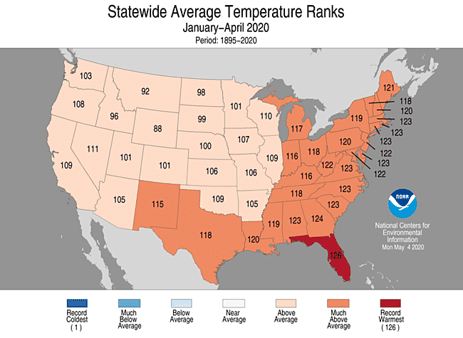

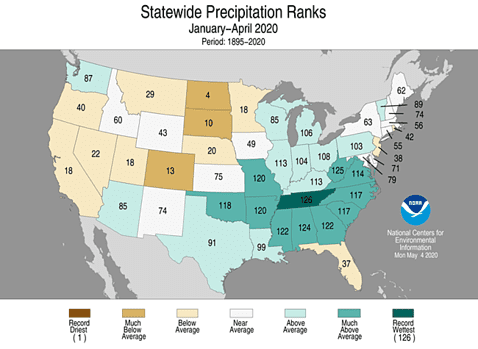

You can see from the graphics below just how prevalent the “above normal” temperatures and precipitation extremes are across the globe.

Organizations must plan now.

Risk management and logistics in this volatile world

For those who manage logistics, the one-two punch of the COVID-19 pandemic and the extreme weather events is making this more challenging than ever. The supply chain is facing unprecedented risks and organizations without a solid risk management plan in place will surely suffer.

COVID-19

Let’s talk about COVID-19 first. According to Johns Hopkins University, the supply chain has a few factors working against it during this pandemic. First, labor shortages due to illnesses or closed facilities will slow the production of goods and harvesting of produce. Second, ill truck drivers or those opting to stay at home are causing delays in shipments and a shortage of drivers.

Then there are the global supply disruptions. The U.S. isn’t in this pandemic alone. The entire world is suffering, and many global manufacturers and distributors have had to either halt operations or significantly modify them. This causes a chain reaction of delays of goods and services.

Finally, the pandemic has caused an increased demand for consumer goods. Some grocery chains are seeing growth in excess of 30 percent year-over-year and online sales of consumer-packaged goods have increased by 56 percent. This kind of demand puts pressure on an already struggling logistics industry that has experienced restricted or halted flights, quarantined ships and port lockdowns, and labor shortages due to COVID.

Climate and weather

As already noted, the extreme weather and temperatures have always been a thorn in the side of logistics leaders. With events only increasing in number and severity, the supply chain is at constant risk for disruptions and escalating costs.

Above-average temperatures may require companies to spend money on reefer trucks for increasingly more freight. Floods from excess rainfall or hurricanes may delay shipments by days or weeks or necessitate route changes that extend delivery timelines. Increased wildfires or washed-out bridges may make traditional lanes impassable.

For organizations dependent upon on-time deliveries, relying on manual or outdated methods to track weather events and climate issues is a recipe for disaster. Every type of freight, mode of transportation, scheduled route, weather and temperature, and delivery commitment has to be considered across each shipment. This amasses an enormous amount of data – data that is constantly changing as rapidly as the weather, putting organizations at high risk for missing those delivery commitments.

Predictive intelligence to manage risk

Some risk is avoidable. It’s the unpredictable risk that is most challenging to manage, particularly if you’re doing it manually. In order to survive this COVID-19 crisis and all of its ramifications, and to account for the extreme weather and climate issues that face us, it’s more important than ever to embrace technology.

Data analytics is nothing new, but it has taken time to combine it with predictive analytics and push it into the world of logistics. When the right software is used, however, identifying all of your risks and understanding how those risks may or may not impact your deliveries is much easier. For instance, the software models temperatures every 10 miles for an entire lane for a shipment for the next 14 days. This shipment simulation is then scored based on the predicted temperature the load will experience, as well as the type of equipment that will offer the best chance for that shipment to arrive on time, in full, and at the lowest possible cost.

The software integrates into your S&OP, ERP, or TMS systems up to two weeks before the shipment leaves the dock, giving logistics professionals plenty of time to manage risk. Effective risk management can only happen when you have this kind of operationalized data at your fingertips.

Protect cargo

When you know the types of risk your shipments are likely to encounter, you can plan ahead to mitigate those risks so your cargo arrives when you said it would in the condition your customers expect. You can combine labor data with weather data to more accurately plan shipments and make commitments you can keep.

Reduce costs

Understanding weather conditions along the entire route of your shipment ahead of time enables you to select the right equipment. In fact, you can use weather data to actually reduce costs. For instance, if your data shows you that temperatures along a particular lane have a high likelihood of remaining below 20 degrees, you may no longer need to spend money on a temperature-controlled truck.

Manage risk

Risk management begins with being able to identify your risks and ends with knowing how to mitigate those risks. The right technology automatically detects, analyzes, and scores your specific risks and then recommends appropriate mitigation efforts. This kind of insight saves you time and ensures you can make decisions with confidence.

We are living in a strange time, full of unknowns and, therefore, unpredictability. Whether it’s a pandemic, the weather and climate, or other potential disruptors to the supply chain, predictive intelligence can help keep your head above the water.

The Everstream Solution

To speak with an expert about protecting cargo, reducing costs, and mitigating risks within your supply chain, contact us now.