Our world is becoming increasingly aware of the emissions impacts associated with global supply chains and associated freight demand. Assuming business as usual, freight demand is expected to triple by 2050, causing the transportation of goods to become the highest GHG emitting activity globally.

Companies are now expected to track, report, and mitigate emissions from across their supply networks. Building this capability into supply chain risk management systems is an efficient way to integrate compliance efforts with existing business operations.

What is the supply chain carbon footprint?

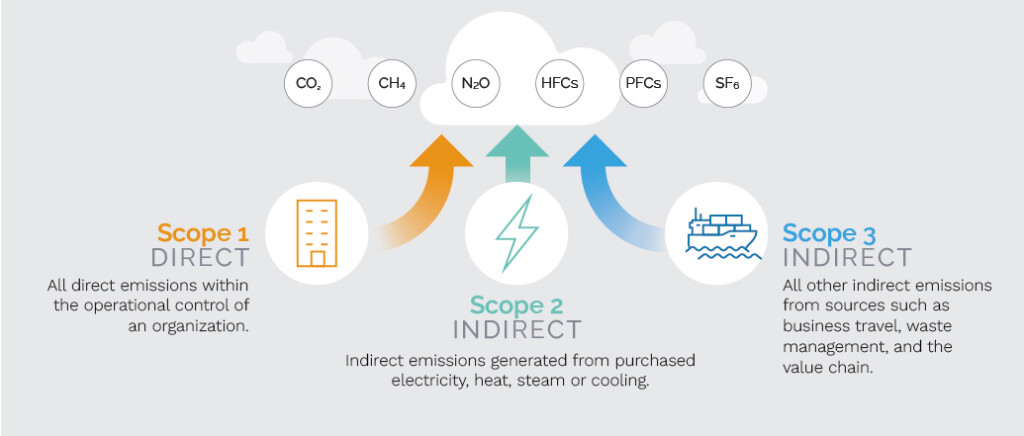

When it comes to tracking and reporting for compliance, a “carbon footprint” is commonly broken down into three categories: Scope 1, Scope 2, and Scope 3. Each covers an increasingly wide range of emissions related to operations:

Figure 1: Carbon footprint supply chain management is usually broken into three categories with varying levels of emissions included.

Supply chain emissions are 11.4 times higher than operational emissions, constituting about 92% of a company’s overall GHG emissions. Further, the International Sustainability Standards Board (ISSB), the leading voluntary sustainability reporting framework, requires reporting on Scope 3 emissions. This emphasizes the pivotal role of Scope 3 (indirect supply chain) emissions in supply chain emissions management and associated reduction strategies.

GET OUR WHITE PAPER TO LEARN ALL ABOUT CARBON INTENSITY AND HOW TO OPERATIONALIZE IT

Companies are increasingly required to track and report the full range of Scope 3 emissions across their supply networks, and new supply chain risk management technology is helping.

Measuring the supply chain carbon footprint

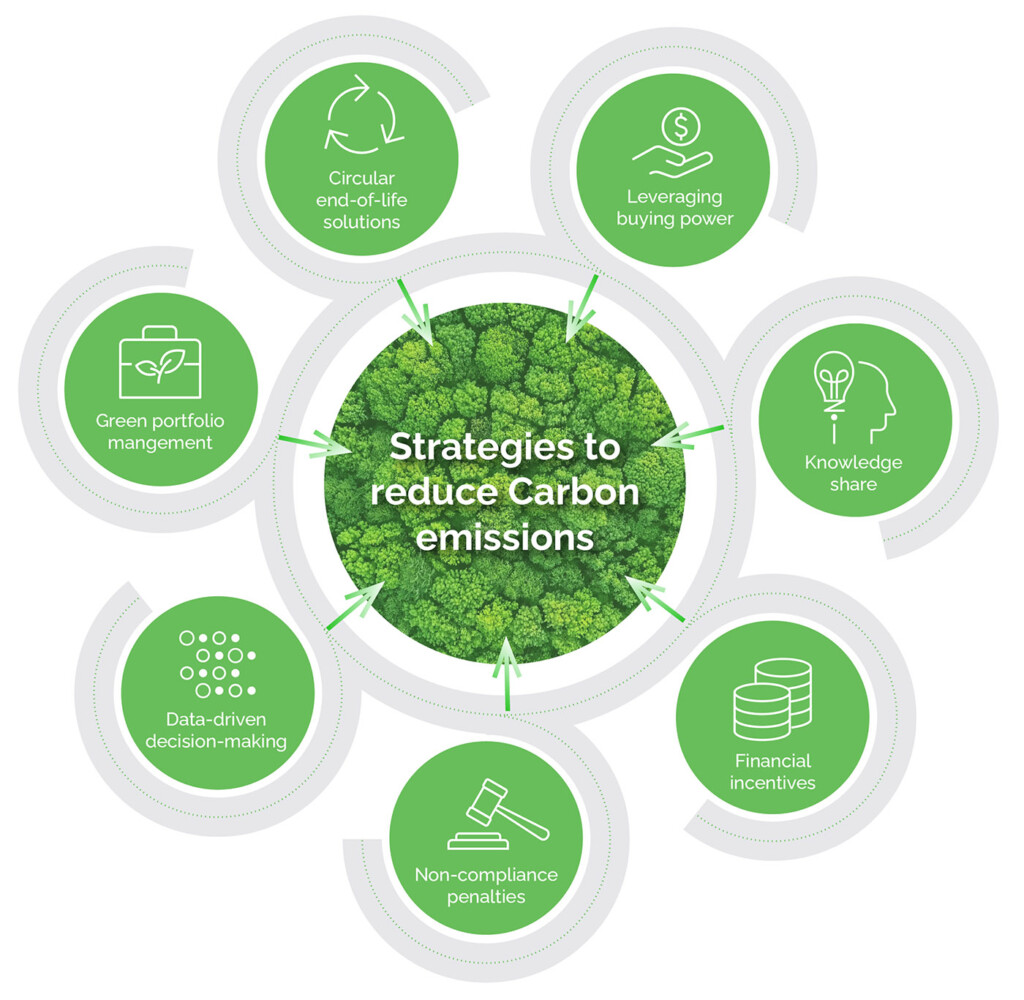

Figure 2: Companies have multiple management areas in which supply chain carbon footprint can be reduced.

Measuring Scope 3 emissions involves a multi-step process. It begins with defining organizational boundaries and proceeds to assessing various categories of upstream and downstream emissions, such as material acquisition, distribution, and end-of-life. Measurement methodologies include both primary (e.g., spend-based data, supplier surveys, life-cycle assessments) and secondary data sources (e.g., industry averages, proxy data, generic data), each with its strengths and limitations.

Understanding and effectively reducing supply chain emissions impacts is complex. Addressing this challenge requires a diversified approach. Recommendations from industry leaders include:

Leveraging buying power to decarbonize procurement and logistics. This could include building obligatory carbon reporting and reduction criteria into procurement or logistics requirements, integrating carbon reduction clauses into performance management agreements, incentivizing implementation or adoption of lower carbon technologies, or enacting penalties (such as contract termination) in instances of non-compliance.

Disseminating knowledge among suppliers and shippers. This could include sharing insights and best practices derived from carbon-reduction endeavors, providing competitor carbon benchmarking information, creating supplier forums and workshops, developing best practices for routing and service level based on carbon, or education initiatives to enhance skills related to decarbonation.

Offering financial incentives for supplier and/or shipping emissions reduction initiatives. This could include performance-based compensation for reaching certain emission-reduction goals, investing in projects with partners that significantly reduce carbon emissions, or offering preferential payment conditions to suppliers or service providers who are able to meet carbon-reduction targets and associated annual reporting.

Implementing penalties for non-compliance. This could include threatening to claw back financial incentives received to date such as preferential payment conditions, enacting financial penalties when suppliers or shippers are unable to meet contractual requirements, or terminating the contract altogether.

Data-driven decision-making. This could include using data-cleansing software, IoT sensors, AI-analytics, machine learning, blockchain or other technological solutions to collect, track, analyze, report, and reduce emissions within the supply chain.

Circular end-of-life solutions. This could include requiring the use of recycled inputs (energy, water, materials, etc.) within the supply chain or partnering to optimizing return routing of containers or trucks, which have the potential to decrease emissions both upstream and downstream.

Green portfolio management. This could include building on existing capabilities to develop new green business segments or investing in technological advancements like renewable energy opportunities.

Specific emission reduction levers identified by Science Based Targets initiative (SBTi) include business model innovation, supplier engagement, procurement policies favoring low-carbon alternatives, product/service design for lower lifecycle emissions, customer engagement, operational policies, and investment strategies in low-carbon projects.

Carbon intensity for supply chain management

Measuring carbon intensity has emerged as an innovative approach. This evolving metric assesses a company’s emissions relative to economic output or other indicators relevant to business operations. Companies can, for example, measure emissions per employee, per square foot, per revenue or spend, or per product. This approach facilitates meaningful data-driven decision-making.

Transitioning from insight to action, Everstream employs the following strategies when approaching supply chain emissions management:

Data precision and transparency: Everstream champions accurate emissions reporting practices relying on activity–based emissions calculations when available and establishing robust data collection mechanisms and partnerships to get the most accurate carbon calculations available. All carbon calculations are conducted using industry leading frameworks, like GLEC, to insure our insights support transparent reporting practices and sustainability strategies.

Technology integration: Leveraging cutting-edge AI-powered analytics, Everstream enhances data gathering, interpretation, and predictive modeling, elevating accuracy and enabling proactive decision-making in emissions reduction initiatives.

Stakeholder collaboration: Everstream advocates for comprehensive stakeholder engagement across the supply chain, fostering alignment toward common sustainability goals. Partnerships and collaborative initiatives enhance data sharing and drive collective efforts toward emission reduction.

Continuous improvement: Sustainability is an iterative journey, and Everstream supports ongoing evaluation, adaptation, and improvement in sustainability strategies, recognizing the evolving nature of sustainability initiatives.

Everstream is constantly working to integrate established methodologies and evolving metrics (like carbon intensity) with our cutting-edge approach to analytics to help our customers understand the complexities of emissions and develop actionable reduction strategies.

GET OUR WHITE PAPER TO LEARN ALL ABOUT CARBON INTENSITY AND HOW TO OPERATIONALIZE IT

Heather Kosztowny is the Director of Data Science for Everstream Analytics, leading development and implementation of transportation modeling and optimization insights. Her 15 years of experience in data analytics and modeling have focused on logistics issues and carbon emissions evaluations and insights.