A control tower is the ultimate tool to manage supply chain risk, creating centrally steered risk management. While the most advanced control tower structure incorporates predictive insights into supply chain orchestration, control towers can begin by simply centralizing risk management.

What is a supply chain control tower?

The goal of a control tower is to help companies sense and respond to what’s going on in their supply chain – issues as well as opportunities. A control tower connects all the supply chain systems, partners, and processes in a single shared view or dashboard that provides alerts, actionable insights, as well as decision support tools and different levels of response mechanisms to truly sense and respond to supply chain issues and opportunities.

While control towers used to be about creating basic visibility, now they incorporate multiple data sources and digital solutions providing insights that help managers take action.

Types of supply chain control towers

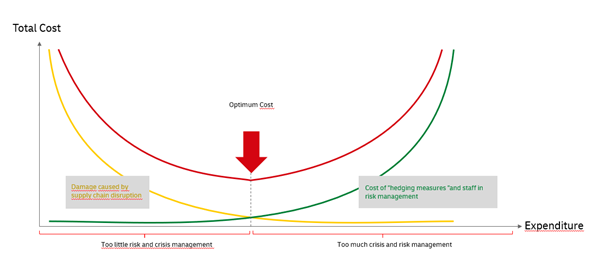

A control tower is a big investment in personnel and IT and there needs to be a balance, as not every company will face enough ongoing supply chain disruption to justify this investment. Once a company has made the decision to begin building a control tower, there are multiple structures and starting points to consider.

Figure 1: Measuring return for supply chain control tower investment.

Logistics/transportation control towers

Often the start of control tower developments, logistics/transportation control towers offer advance shipping notifications, delivery data, and track-and-trace information — and visibility into inbound and outbound logistics.

Fulfillment control towers

Also called planning control towers, fulfillment control towers specialize in assisting package shipments and are designed to help expedite orders while reducing the overall cost-to-serve.

Inventory control towers

Inventory control towers enable real-time insights into inventory management, with special emphasis on preventing inventory stock-outs and shortages. Here, supplier information can merge with logistic information, but the control tower team still is logistic focused.

Supply assurance control towers

Supply assurance control towers ensure there’s an adequate supply available, that more supply is planned for delivery, and other matters related to supply. This is where purchasing and logistics can converge into one control tower.

E2E control towers

E2E supply chain control towers are engineered to provide visibility across internal and external systems and processes, with applications for various departments or entities.

How to get started on supply chain control towers

Building a control tower is a transformation effort that has as much to do with people and process changes as it has to do with software and solution design. It needs the right people, technology, and data to achieve its goals. Here are some high-level bullet points on how you can go from design to execution:

Design stage

Have a vision of your supply chain strategy and a vision of what the control tower should achieve to help you get there. Share this vision with all stakeholders.

Understand that this is a journey, and one that will require ongoing maintenance once the control tower structure is complete:

- Integrating partners (carrier, suppliers).

- Improving data quality and aligning measurements (cleaning data, then building measurements of success).

- Move to more advanced optimization and orchestration capabilities, but risk should be the vehicle to start.

Build the right toolset for success:

- Transport Management System to orchestrate the core process and get into control of logistic activities, plus invoicing operations. TMS is the most foundational system to start with.

- A dashboard portal to drive analytics.

- If warehousing is involved, a warehouse management system should be part of the landscape.

- If purchasing is getting involved, onboard a supplier relationship management system.

- Connect carriers using tools from a company like Inttra, p44, Fourkites or Transporeon. These companies can also provide real time visibility.

- Additional analytics and visibility modules serving specific purposes can be added.

Execution stage

When building there are some key considerations for your team to decide.

One or many control towers? Considerations need to be done by geography, business units, etc. You will need one central control tower, which manages data harmonization and steers the other control towers to ensure stringency.

Where do I locate my control tower? It needs to be close to operational locations, but more importantly close to decision makers. It is better to have it sit in a central HQ than in a plant, as some important decisions must be made quickly and for the broader network.

How sensitive is my logistics chain? Deciding between milestone or GPS tracking should be based on sensitivity. The overall technology stack should be defined by this as well. Avoid an information overflow and focus on the right insights instead of simply gathering a lot of data.

Visualization, control, or orchestration? Visualization was the primary goal for many years, but the value is limited because you will only know when an issue happened. Controlling is about making sure the right actions can be taken with the right approval flows. Orchestration is about having predictive insights that empower an organization to make decisions and react quickly.

Adding risk management to supply chain control tower structures

There are three ways risk management data informs control tower development.

Real-time, end-to-end visibility. Establish end-to-end visibility across your entire supply chain, including sub tiers, with a control tower that correlates data across siloed systems with external event information to provide actionable insights into potential disruptions – all in personalized dashboards – so you can manage the exceptions.

Predictive and prescriptive decision support. Better predict disruptions and improve resilience with smart alerts and real-time actionable insights to help you understand the upstream and downstream impact of events on customers and prioritize your response.

Collaborative information sharing. Better collaborate on and manage exceptions across the entire supply chain with AI-powered resolution rooms and digital playbooks, combined with supply chain applications that help you quickly respond to unplanned events and hone execution to drive KPI performance.

Building a control tower makes sense for many companies, particularly ones transitioning to enterprise-level operations, and supply chain risk management can be the driver. Only with risk-sensing capability can the supply chain be proactively managed. Start with risk management data and build from there on your control tower journey.

Get our eBook and learn how to incorporate risk insights into your control tower plan.