Using Artificial Intelligence in supply chain management may feel trendy, but leveraging this advanced technology is more than just keeping up with the supply chain Joneses. AI can easily streamline your supply chain processes, highlighting potential disruptions, monitoring established situations, and suggesting mitigation options.

For the doubters out there, let’s face it: unwieldy and complex global supply chains aren’t likely to become more straightforward and simpler with time, even if companies attempt to nearshore their suppliers as much as possible. Instead, AI can take the complicated nature of these supply chains and help you map and visualize each element, collating data to give you detailed information on a supplier’s history, importance within your supply chain, risk factors, and more.

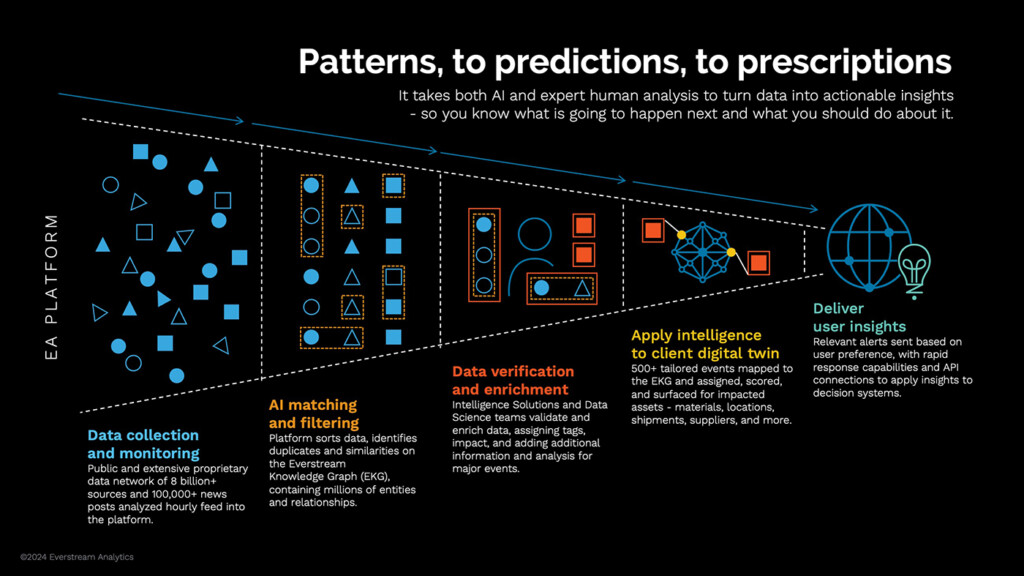

AI is already transforming supply chain management across industries, doing more than just collating data. It helps customers uncover hidden relationships and anomalies within their data, offering insights that enhance their understanding of the supply ecosystem. By simplifying processes and analyzing data, AI enables supply chain experts to make proactive, educated decisions. Here are examples of how companies leverage AI-powered tools for supply chain success.

Case study: Using AI for multi-tier mapping

A large, global CPG company wanted to understand the extent of their supply chain network and inherent risk, especially when it came to climate change. Additionally, the company wanted better information and warnings in relation to suppliers with potential compliance and reputational risks.

Using Everstream’s industry knowledge graph, powered by AI, the company was able to fully visualize their network, including sub-tier suppliers. The graph was created by applying AI to data sources relating to the world’s global supply chain, including import, export, and shipment records. While this would have been manual, error-prone and time-consuming for a supply chain management expert, the AI was able to fuse the data with other sources, producing a network that was easy to understand and that provided actionable intelligence. Finally, human experts from Everstream and the company were able to verify and assess the AI’s output, ensuring accuracy and completeness.

Figure 1: Everstream Analytics engine of AI and ML to generate actionable intelligence

Case study: Using AI to predict the impact of a supply chain disruption

A chemical company needed greater accuracy in their weather forecasting capabilities, as climate events generally had a significant impact on their supply chain operations. Since their climate data had never been as accurate as it could be, they weren’t able to make proactive decisions, or even react quickly enough to prevent disruptions.