Supply chains are the backbone of businesses, and supply chain planners must frequently navigate complexity and unpredictability. From fluctuating customer demand to unexpected disruptions, traditional supply chains often fall short when faced with modern day volatility. This is where an agile supply chain becomes a game changer.

But what is an agile supply chain? Simply put, it is a flexible, responsive, and highly adaptive system designed to respond quickly to changes and uncertainties. Its core characteristics include real-time data visibility, including risk monitoring and actionable alerts, as well as collaboration and scalability.

What is agility in supply chain planning, and why does it matter?

Agility in supply chain management isn’t just about reaction and response. It’s about preparing for, and adapting to, the unexpected. If a demand surge occurs or supply sources get disrupted, an agile supply chain has built-in resilience. This ensures that the business can still provide customer satisfaction without significant delays.

But what is agile supply chain management? It refers to both the practices and tools businesses use to achieve this adaptability. By implementing agile methods, such as real-time analytics and flexible manufacturing, supply chains become better equipped to handle volatility and change.

This blog explores how agile supply chain planning and strategy can help businesses gain an edge. It also answers important questions like, “What is agile supply chain strategy?” and “What are the characteristics of agile supply chains?”

Why an organization should improve supply chain agility

Think about what happens when a factory can’t fulfill demand due to broken communication or rigid processes. Supply shortages. Production outages. Missed deliveries. Damage to reputation and customer trust.

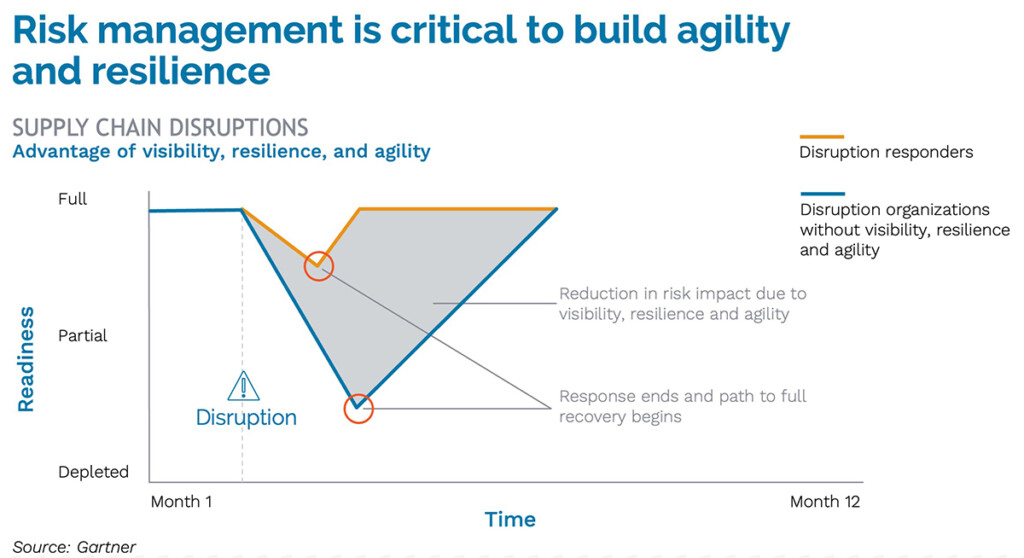

Companies leverage live risk insights into their planning systems to understand vulnerabilities such as weather events, supplier disruptions, tariffs, geopolitical uncertainties, and so forth. This allows a company to balance long-term planning with its risk appetite across product categories.

Improving agility helps businesses pivot effectively during crises. Companies can use near real-time insights to make informed decisions. This could mean adjusting plans to meet demand surges, optimizing inventory levels or shifting production. Agility is not just nice to have. It is a competitive advantage that allows you to increase your market share while others struggle to respond to disruption.

If your business needs to boost efficiency, improve customer satisfaction, and gain a competitive edge, it might be time to explore the advantages of an agile supply chain. Below, we’ll uncover the top five benefits of an agile supply chain and how they can revolutionize your operations.

Advantage #1: Enhanced responsiveness to market fluctuations

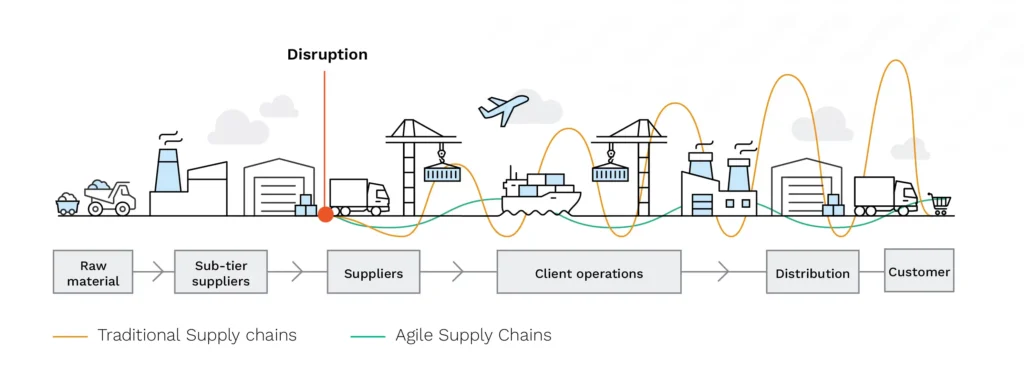

Markets are volatile and unpredictable, as we’ve seen with recent economic shifts, supply chain disruptions, and fluctuating consumer trends. Traditional supply chain models struggle to keep pace with these rapid changes. However, an agile supply chain thrives in such environments by enabling businesses to adapt quickly.

Figure 1: Agile supply chains mitigate the bullwhip effect

How agility drives responsiveness

- Customer demand

Agile supply chains can respond to real-time demand spikes, allowing businesses to scale production up or down seamlessly. Whether it’s a product going viral or seasonal fluctuations, agility ensures you’re always prepared.

- Emerging trends

Spot a new trend? Agile supply chains allow you to pivot, introducing innovative features or new products quickly to capitalize on the opportunity.

- Economic shifts

With advanced solutions, agility helps businesses reconfigure sourcing and pricing strategies during rising costs or challenging trade relationships.

Key agile supply chain characteristics supporting responsiveness

- Flexibility

Adjust production processes, production planning or switch between suppliers to respond to fluctuations in demand.

- Visibility

Real-time data provides insights into demand, inventory levels, and disruptions, enabling quick adjustments.

- Proactive communication

Strong relationships with partners and suppliers allow seamless pivots during challenges.

Businesses with resilient supply chains can gain market share and keep customer loyalty by responding quickly to surprises.