The interconnected nature of supply chains is simultaneously extremely beneficial and burdensome to businesses. Sourcing materials or placing production around the world offers companies a lower cost basis from which to do their business. However, the successful production and transportation of their products depends greatly on how well the different parts of their supply chain work together.

Staying on top of short-term risk assessments is key to staying alert to emerging issues and making effective mitigation decisions. This is especially true within the world of supply chain logistics, which already relies on a delicate balance of transportation options, good weather, and conducive geopolitical situations. Therefore, it’s no surprise that the nature of logistics risk assessments are changing as quickly as the logistics risk landscape is changing.

Businesses must understand the key emerging risks within their supply chain logistics by running accurate and functional risk assessments. Armed with the relevant data, supply chain logistics managers can make the necessary adjustments for supply chain success.

What to consider in a logistics risk assessment

Acute logistics risk assessments aren’t a one and done kind of task. Rapid changes within the supply chain ecosystem mean that point-in-time snapshots of the state of your supply chain will only last so long. Having a continuous view into your acute logistics risks means that your company will be able to make decisions on an ad hoc basis, as issues are developing. Of course, it can be helpful to keep an eye on historic data for future reference. However, if you’re waiting for the next scheduled review, your risk mitigation actions will likely be too late.

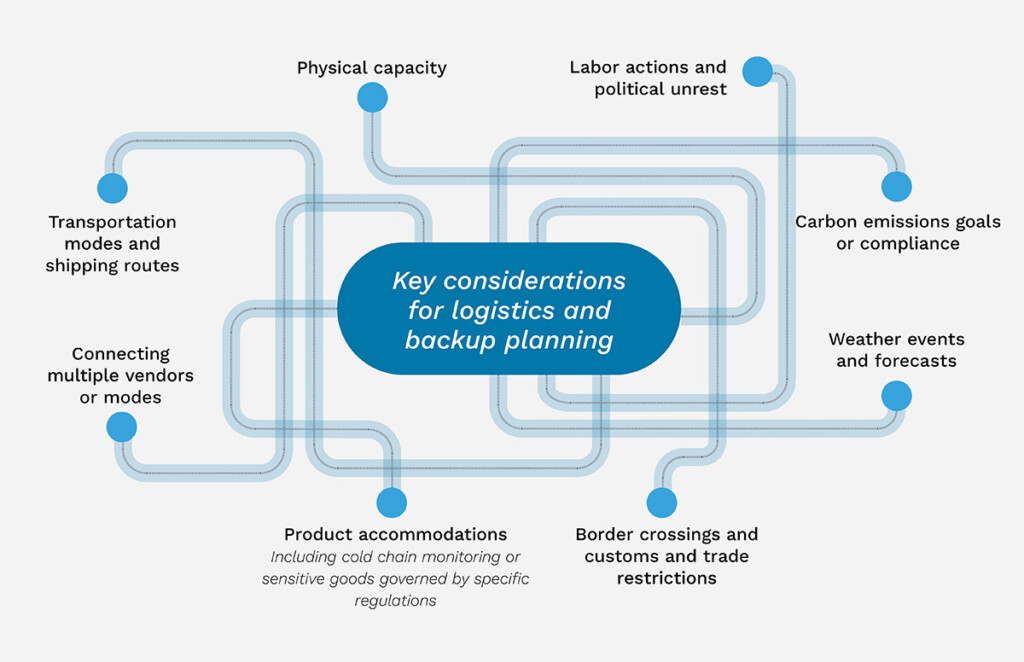

Figure 1: Multiple elements go into today’s acute logistics risk assessments.

LEARN HOW TO BALANCE LOGISTICS EFFICIENCY AND RESILIENCE IN OUR NEW WHITE PAPER: DOWNLOAD NOW

Furthermore, not all risk data is created equal. It’s worth taking the time to set up your logistics risk assessments properly, with relevant global data from a variety of trusted sources. Relying on one source alone may mean that you’re missing out on key information that you can base your next actions on. And, similarly, regularly checking that you’re getting the logistics data you need to make informed decisions goes a long way to creating an effective risk management system.

Unfortunately, there’s no cut-and-paste logistics risk assessment that will work for every company. However, we now have advanced tools to more accurately evaluate logistics risk. AI-powered predictive analytics are more likely to accurately highlight emerging issues. The combination of continuous monitoring, advanced analysis of ongoing risk data, and historic trend gives businesses the best possible information for logistic risk assessments.

Creating your logistics risk assessment process

No two logistics risk assessments will look the same, as acute concerns will vary by supply chain. However, there are a few principles that will likely apply to all companies looking to understand the scope of their risk landscape.

Political circumstances. Suppliers around the world may be impacted by ongoing and emerging political situations, which may hamper their ability to produce or ship materials and products. Knowledge of potential political situations that may affect your logistics will give you enough heads-up to make changes to suppliers in another area or order ahead to prevent any delays within your supply chain.

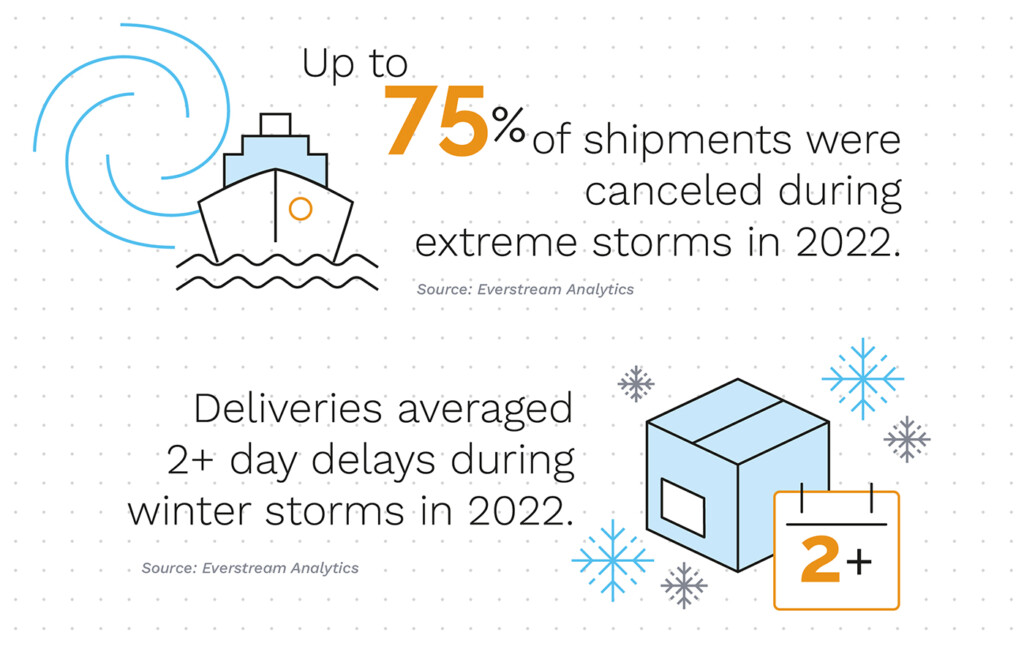

Extreme weather events. Climate change has increased the amount of extreme weather that occurs throughout the year, ranging from unexpected droughts or torrential rain to out of season storms and more. These weather events can create material scarcities or interrupt transportation flows, creating a logistical nightmare. While you may not always have foresight of these events, understanding their impact and potential alternatives is an important part of logistics risk assessments.

Figure 2: Extreme weather is increasing, and drives more logistics delays and cancellations.

Regulatory implications. Every country has separate trade and manufacturing legislations that govern global supply chains. Most industries also have differing regulations, depending on the materials or products in question. And, with the specter of various net-zero regulations looming, companies may find that their current ways of doing business may not fly anymore. Getting ahead of changing regulations and maintaining compliance with current ones will help you avoid costly fines or delays in business.

Agility within your logistics. What is your plan B? And how easy is it to switch over it plan B, C, and so on? There are some areas within logistics your company may not be able to control. For example, certain materials can only be sourced from certain countries, creating a higher risk that is harder to mitigate against. However, other logistics risks may be easier to manage if something goes wrong, such as redirecting shipments to different ports or using different suppliers for certain logistics tasks. Knowing what your options are before you hit a crisis point ensures that you can keep your business running smoothly in the face of disruptions.

What has worked before? Decision-making shouldn’t rely solely on historic trend data, but it can be helpful to recognize the elements that created the environment for successful logistics. Remember, this should be one data point of many within your logistics risk assessments.

Supply chain logistics are far from simple. If you want smooth, uninterrupted operations, you need to make risk mitigation decisions quickly and effectively. Getting on top of your logistics risks assessment process is paramount to spotting problems as they develop so you can get ahead of the issue and ahead of your competitors. However, issues can pop up from any area within your logistics operations, so it’s best to create a comprehensive risk assessment plan to catch them all. Now’s the time to work with your supply chain team to find the best way to continuously monitor logistic risk data, automatically analyze it for disruptions, and make the best possible logistics management decision.

LEARN HOW TO BALANCE LOGISTICS EFFICIENCY AND RESILIENCE IN OUR NEW WHITE PAPER: DOWNLOAD NOW

Heather Kosztowny is the Director of Data Science for Everstream Analytics, leading development and implementation of transportation modeling and optimization insights. Her 15 years of experience in data analytics and modeling have focused on logistics issues and carbon emissions evaluations and insights.