Supply chain disruptions are inevitable. As a result, supplier risk management is a critical area for procurement teams. By monitoring and assessing supplier risk, enterprises build operational resilience, mitigate disruptions, and maintain a competitive edge. This is risk-optimized procurement.

Why managing supplier risk is important for procurement teams

From natural disasters to regulatory compliance, you cannot ignore the risks lurking within your supplier network.

Every procurement decision comes with a degree of uncertainty. Supplier risk takes center stage when those uncertainties jeopardize outcomes like timely deliveries, quality control, and ethical sourcing.

The hidden consequences of overlooking supplier risk

Global supply chains have never been more interconnected. However, with these connections come vulnerabilities.

Figure 1: Lack of sub-tier visibility impacts a company’s response time to disruption

Multiple tiers can hide critical risks. This is especially true with sub-tier suppliers you might not know about. While it is not possible to eliminate all potential disruptions from your supplier base, you can significantly reduce risk.

For example, single sourcing critical parts or raw materials is a high-risk procurement strategy. This can have unexpected impacts on your operations, financial health, and reputation.

Sometimes this is unavoidable. Consider China’s control over in rare earth minerals and magnets. Beijing’s recent export controls left automotive, electronics, and other manufacturers scrambling to avoid production stoppages.

However, where possible, you should consider dual or multiple vendors to mitigate risk.

Operational Disruptions

Imagine that your primary supplier is affected by a hurricane, or a vendor faces labor strikes. Without alternative sources lined up, or expensive buffer stock, your operations could come to a grinding halt.

Cost Overruns

Supplier risks often translate into higher costs for expedited shipping, inventory stocking, or sourcing last-minute replacements.

Reputation and Regulatory Risks

A non-compliant supplier engaging in unethical labor practices can tarnish your brand’s reputation. This could result in government authorities seizing your goods and imposing fines.

In addition, this could damage your reputation with your customers. Modern consumers and businesses are increasingly concerned about the social and environmental impact of the products they purchase.

Supplier risk assessment vs. ongoing monitoring and alerts

The first step is supplier risk assessment. To do this, you need both external and internal risk data. This gives you the baseline, location-based strategic risk scores.

External risk factors

Think of supplier risk assessment as your starting point for evaluating existing and potential vendors. External risks to consider include:

Natural disasters and weather risks: Is the supplier in an area prone to earthquakes? How about tropical cyclones, tornadoes, or hurricanes? Is drought or flooding likely?

Financial risk: How financially stable is the vendor? How long have they been in business?

Socio-political risks: Is the vendor in a region experiencing civil unrest? What is the frequency of industrial action and strikes?

Regulatory and ESG risks: Is there a chance of forced labor or child labor in the supplier’s supply chain? Did someone accuse them of corruption? Will they negatively impact your sustainability targets?

Internal risk factors

If you are evaluating an existing supplier, you should include any internal risk data. This could include:

Performance and reliability: How often are deliveries on time and in full? Have you had quality concerns about their products?

Business volume and frequency: How often do you purchase goods from this supplier? What amounts do you purchase?

Supplier relationship: How long have you been doing business together? Are they trustworthy? Do they prioritize your business when disruptions occur?

Material criticality: How reliant are you on this vendor? How easily can you find an alternative supply of these goods? Are they vital to your long-term strategic goals? What would be the impact on your business if this vendor went bankrupt?

Network mapping and monitoring

It is important to understand that risks evolve. Static data won’t alert your team about sudden regulatory changes, financial instability or forecasted extreme weather conditions.

Mapping your network creates a digital twin of your supply chain. This includes your suppliers, supply lanes, locations, and distribution hubs.

This location-based mapping allows you to continually monitor and receive alerts to emerging threats.

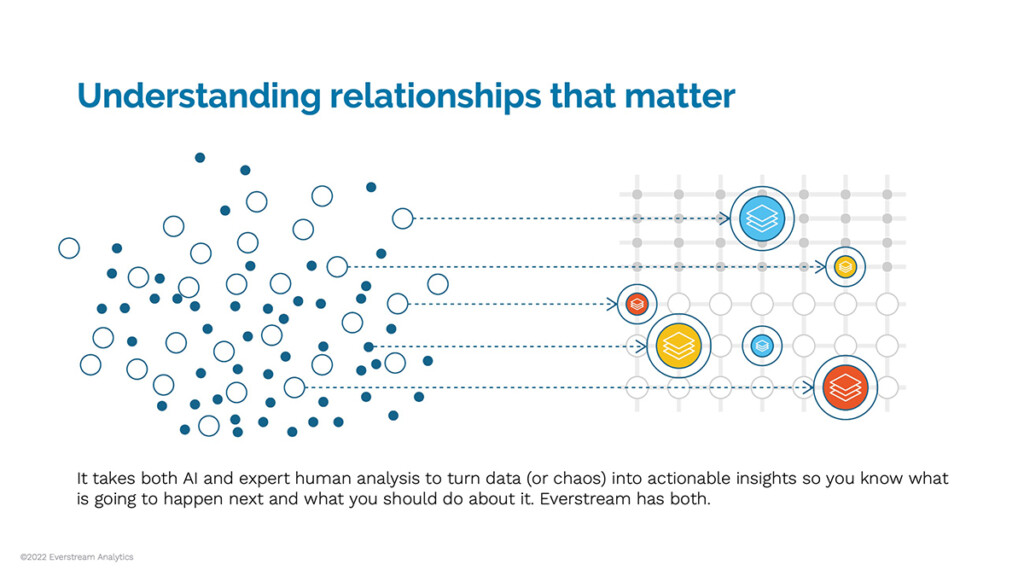

Ideally, your solution should have a combination of AI filtering and human validation. This will allow you to stay informed without alert noise.

Figure 2: AI with human oversight is needed for actionable insights to disruption

Key Advantages of Monitoring Systems:

- Actionable Alerts: Imagine knowing about a political protest blocking port operations before it delays shipments.

- Customizable Alerts: Tailor notifications to your critical thresholds. For example, receive alerts when a key supplier breaches compliance metrics.

- Proactive Problem-Solving: Solve small issues before they spiral. Quickly adjust sourcing plans in response to alerts.

Combining supplier risk assessments with real-time monitoring creates dynamic, actionable insights. This could include:

- Plant closures

- Fires

- Chemical spills

- Flood risk

- Industrial action

- Geopolitical tensions

- Bankruptcy