In the bustling world of logistics and procurement, supply chain risk refers to the potential for disruption in the procurement, production, distribution, and sale of goods. It’s a looming thundercloud that can affect any aspect of your business operation. Imagine this: you’re a puzzle master, but pieces from your neatly organized set start vanishing or changing shape – frustrating, right? That’s supply chain risk in a nutshell.

Supply chain risk in logistics

Logistics issues have hit us all. Typically, it’s the holiday season, the time when shoppers are on the hunt and sales usually soar. But often, the hottest products are stuck in a port because of a customs issue, or a transport strike has thrown a wrench in the works. It can be as challenging as sailing through a tempest with holiday profits on the line.

These aren’t just little ripples to step over—they’re potential swells that can rock your entire fleet. So, what exactly should you be keeping an eye on?

The customs Kraken: Ever feel like releasing the Kraken on slow-moving customs procedures? Delays caused by customs can entangle your shipments as effectively as any sea monster’s tentacles. Do you have the right crew and paperwork to navigate these treacherous waters?

LEARN MORE ABOUT HOW SUPPLY CHAIN RISK MANAGEMENT WORKS: FREE REPORT

The inventory maelstrom: Balance is key when sailing, and the same goes for your inventory levels. Overstock can capsize your cash flow, while understock can leave your customers marooned. Are you equipped with the tools to navigate this whirlpool of inventory management?

The transportation typhoon: Just like a storm at sea, transportation can be unpredictable. Strikes, fuel cost tsunamis, and carrier breakdowns can scatter your fleet to the wind. How do you keep your ship heading true when the transportation weather turns foul?

The warehouse reef: A poorly managed warehouse can be as hidden and hazardous as a subtropical reef, ready to ground your operations with inefficiency and error. Are you charting a safe path by streamlining your warehouse processes and training your crew?

By spotting these logistics challenges from your crow’s nest early, you can sail smoothly through the supply chain seas without throwing your budget overboard.

Supply chain risk in procurement

Let’s dive into procurement risks. Remember when a certain canal got blocked by a ginormous container ship, causing global trade hiccups? Or closer to home, when your go-to supplier suddenly couldn’t fulfill orders because of an unexpected raw material shortage? These are vivid examples of procurement risks. As a manager, these are the tides you must be ready to navigate.

Let’s examine some more procurement risks that you might bump into:

The single source shuffle: Essentially, “Don’t put all your eggs in one basket.” This old saying rings especially true here. Relying on a single supplier is like trying to balance on a one-legged stool. What happens if that leg gives out? Your operations can topple over if you don’t have a backup plan.

The price surge wave: It’s like enjoying a day at the beach until a rogue wave hits and your wallet gets washed away. Global events or market changes can cause prices to surge unexpectedly. Are you ready to surf these waves without wiping out your budget?

The compliance compass: Keeping true to the laws and regulations is your compass in murky waters. But what if this compass starts spinning unpredictably due to new legislation or trade agreements? Are you nimble enough to adjust your bearings and stay the course?

The quality quagmire: No one likes a treasure chest filled with fool’s gold, right? Compromising on quality can lead to huge losses. Are you checking if your supplier’s standards are as pristine as a well-polished compass, or are you at risk of sinking in a quagmire of defects and recalls?

The innovation inlet: Finally, we’re all searching for that secret inlet that leads us to new innovations. Are your suppliers staying afloat on the sea of modern advancements or are they anchored to outdated practices? Partnering with innovators can lead you to uncharted, prosperous lands.

By keeping an eye on these procurement risks, you’re equipping your ship with the sturdiest of sails and the strongest of hulls.

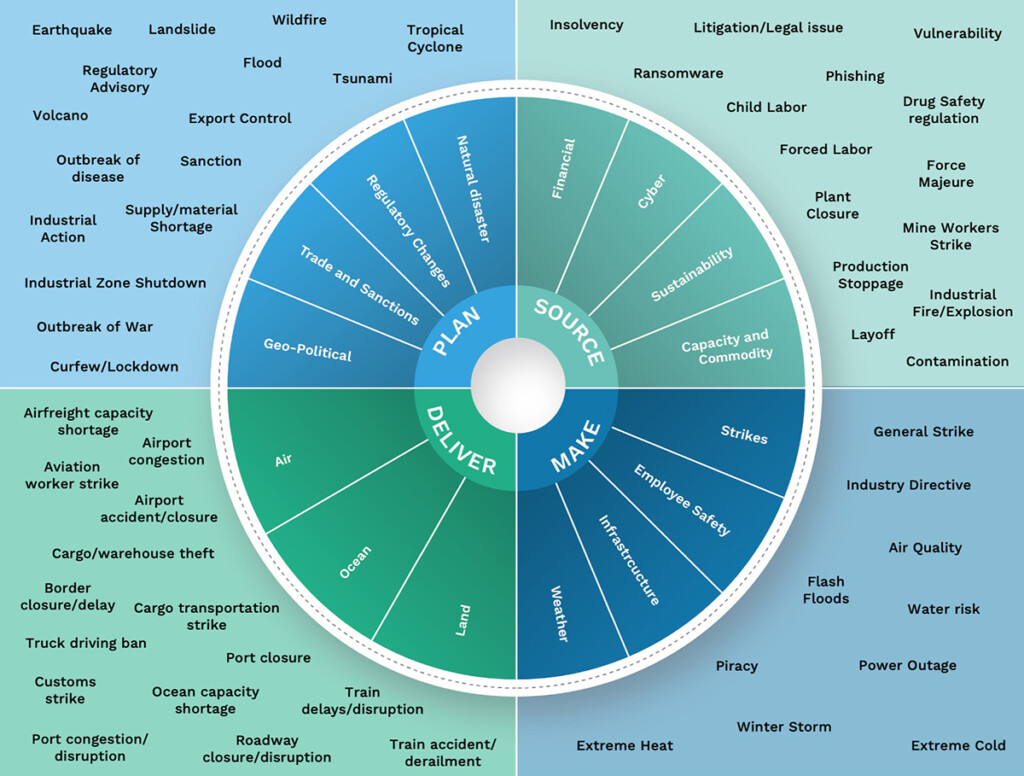

Figure 1: Supply chain risk cuts across multiple operational areas in planning, sourcing, making, and delivering product.

Easing the supply chain with proactive risk management

Managers can ease the flow of goods by identifying risks early and charting a course to safer harbors. It’s about having that figurative weather radar to foresee storms and having your sails ready to pivot with the wind. Building strong relationships with suppliers, deploying advanced technology and digital mapping, diversifying your routes, and keeping a keen eye on quality control are your best navigational tools.

In a sea of uncertainties, one thing is clear: foreseeing and mitigating supply chain risks is essential to not only maintain smooth sailing but also to secure the treasures of profitability and success.

LEARN MORE ABOUT HOW SUPPLY CHAIN RISK MANAGEMENT WORKS: FREE REPORT