Storms, flooding, high winds, extreme temperatures and other natural disasters can be devastating in terms of loss of life and destruction of property. But they can also upend logistics, leading to production stoppages, product spoilage, lost sales, and empty shelves. Getting ahead of weather disruptions is key to logistics risk management.

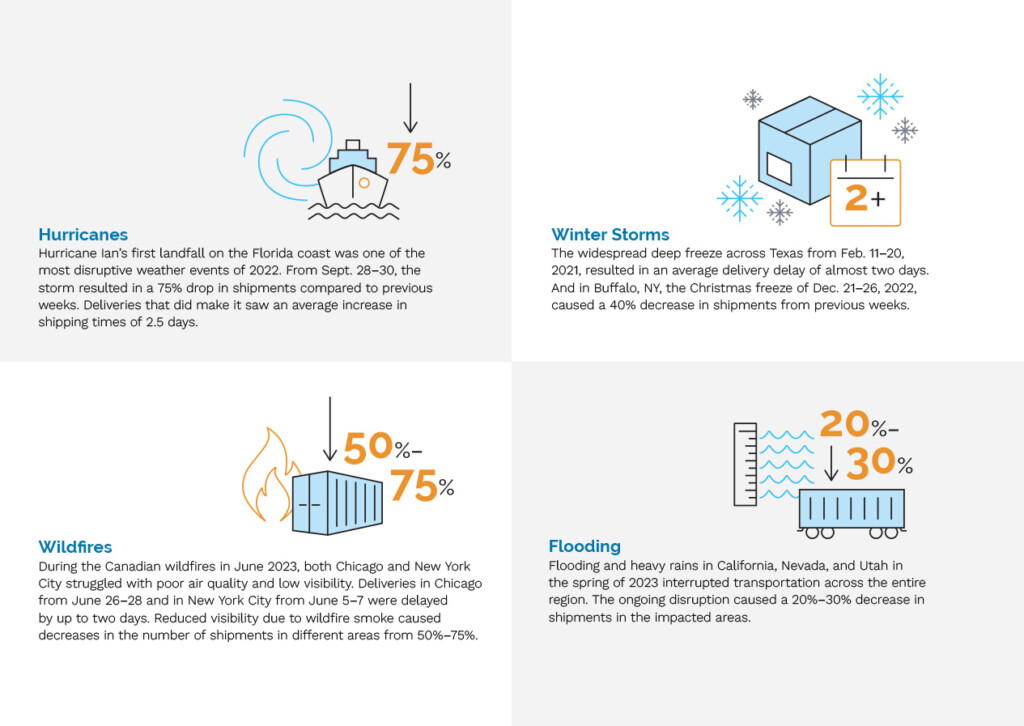

In September 2022, Hurricane Ian carved a devastating path through the Caribbean and southeastern United States. The storm delivered a stark reminder of weather’s growing influence on global logistics, causing a staggering 75% drop in shipments and extending shipping times by 2.5 days across affected regions.

Sometimes it is not just about high wind speeds or heavy rainfall, but rather where the hurricane hits.

Rainfall for 2024’s Hurricane Helene was accurately predicted a week in advance. Unfortunately, the existing infrastructure in the southern Appalachians could not handle the deluge. Bridges, roads, and rails, built for a different climate, were overwhelmed. This widespread failure caused significant damage, impacting over 50 manufacturers across critical sectors like electronics, automotive, aerospace, and healthcare.

Similarly, Winter Storm Uri in 2021 demonstrated how extreme weather events can create hurricane-like disruptions even without the traditional characteristics of a tropical cyclone.

This historic winter storm swept across Texas, causing massive power outages and shutting down transportation infrastructure across the state. Warehouses and production facilities were forced to close for days. Highways became impassable because of ice, severely disrupting freight movement throughout one of North America’s most important logistics hubs.

Figure 1: Planning around weather events can significantly reduce logistics disruptions

Extreme Weather is the New Normal

Extreme weather is becoming more frequent, and its impact on supply chains is intensifying. Where extreme weather events once occurred every four months just four decades ago, today billion-dollar weather disasters strike every three weeks.

The World Meteorological Organization warns of an 86% chance that at least one year between 2025 and 2029 will exceed 1.5°C above pre-industrial levels. This virtually guarantees more frequent and intense weather disruptions

The amplification effects of climate change are particularly evident in the logistics sector. Heatwaves are affecting cargo handling efficiency and storage conditions. This makes it more difficult to maintain product quality during transport and warehousing.

Storm surges are inundating coastal ports with increasing frequency. These result in temporary closures that can paralyze entire regional supply networks.

Wildfires are creating air quality and road safety concerns that extend far beyond the immediate fire zones. These can affect transportation corridors hundreds of miles away.

The economic impact of these changes is staggering. Research indicates that the economic risks of climate change to global trade could reach approximately $81 billion. That is without factoring in economic activity linked to industry output and consumption.

The implications for logistics are profound. Supply chains that were designed for predictable weather patterns now face unprecedented volatility.

The Ripple Effect of Weather Disruptions

Port operations are particularly vulnerable to hurricanes, storm surges and high winds, since they are in coastal areas. When weather forces port closures, container ships seek alternative ports. These may be hundreds of miles away, adding days or weeks to delivery schedules.

The backup at alternative ports creates congestion that can persist long after the original port reopens. Maritime shipping schedules become chaotic when vessels reroute and delay.

Roads can become impassable because of flooding, debris, and structural damage. High winds can wash out or damage rail tracks. Airports may face extended closures because of winds, flooding, power outages, or infrastructure damage.

Extreme temperatures can disrupt rail networks and road freight operations. Overheated tracks and infrastructure malfunctions caused service cancellations and cargo spoilage.

Because transportation modes are interconnected, disruption to one system can result in knock-on impacts to other modes. When trucking routes are blocked, there is increased demand for rail transportation. If an airport closes, shippers may turn to ground transportation, often at the very time when road conditions are most challenging.

Weather is responsible for 23% of all road delays in the United States. These disruptions cost trucking companies between $2 billion and $3.5 billion annually. This is because of disruptions to work shifts, in-transit holding costs, late fees, and customer retention challenges.

These direct costs represent only the tip of the iceberg, as indirect costs from inventory disruptions, customer dissatisfaction, and lost sales often exceed the immediate operational expenses.