Procurement professionals and supply chain managers are like orchestra conductors. They are trying to make musicians – that is, suppliers – across every part of the world work together in harmony. With one hand tied behind their backs, and wearing a blindfold.

Unsurprisingly, there are a lot of discordant notes.

A bankruptcy here; a fire there. Then there are workers strikes, plant closures, floods, hurricanes, or cyberattacks. Not to mention regulatory changes, geopolitical tensions, and trade wars. Plus, your own organization’s ESG and sustainability targets.

Suppliers are the lifeblood of any organization. However, they also pose the biggest threat as well. It is not possible, or even desirable, to remove risk entirely from your supply chain, but risk can be managed and mitigated.

Managing hundreds, or even thousands, of your own direct Tier-1 suppliers is a significant challenge. Add in your suppliers’ suppliers, plus all the risks these pose. Very quickly, the task becomes infinitely more difficult. Here is where AI can help.

Key Applications of AI in Supplier Risk Management

Machine learning algorithms analyze vast datasets to identify patterns invisible to humans. Natural language processing tools scan news articles, social media, and regulatory filings to surface early warning signals. Predictive analytics models forecast potential disruptions before they occur. The beauty of AI lies in its ability to process information at a superhuman scale and speed.

One of AI’s most useful applications is analyzing huge data sets and making sense of them. Here are two of the most compelling use cases for supplier risk management.

Supplier Network Mapping

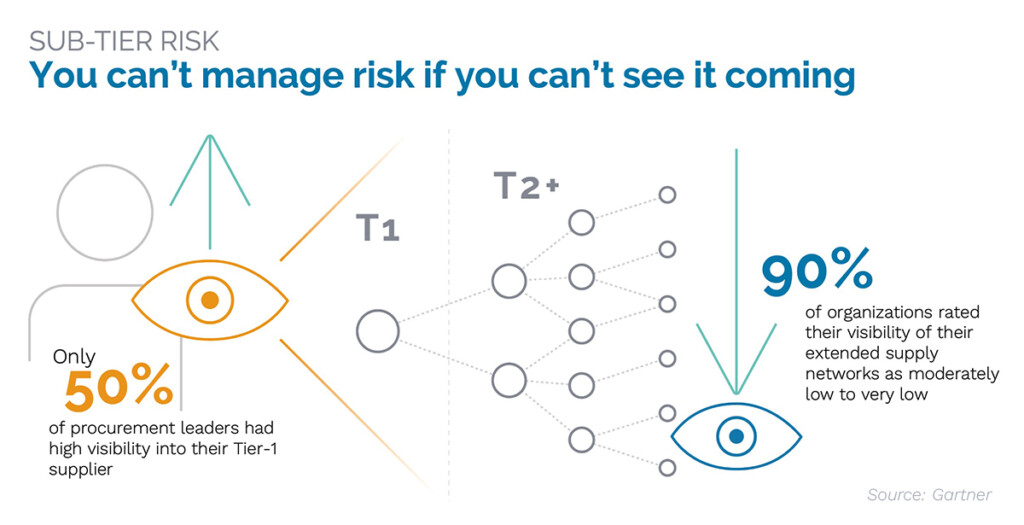

One of the most difficult aspects of monitoring supplier risk is data. You can’t manage risk unless you know where it might be lurking.

Therefore, the first step is to understand your network of suppliers. This could include sub-tier suppliers. This would allow you to monitor risks in your Tier-2 and Tier-3 suppliers before they impact your Tier-1 supplier. Do this in a targeted way, focusing on your most important products, your riskiest regions, or your most critical materials.  Figure 1: AI can uncover the supplier sub-tier network to make risks visible

Figure 1: AI can uncover the supplier sub-tier network to make risks visible

While you may be able to uncover some of this information with supplier surveys, that is unlikely to include all upstream suppliers.

AI algorithms analyze billions of trade records, shipping manifests, and corporate filings to identify hidden connections within your supply chain.

Manually trying to map this network runs into one significant challenge – data quality. Consider how a company’s name is recorded in your enterprise systems. Chances are, that you will find it entered in a variety of ways, such as:

- Multinational A

- Multinational A, Inc.

- Multi-National A

- Multi-National A

- Multinational A, Incorporated

- Multi-National A, Chemical Division

Unfortunately, the data quality challenges do not end there. AI can help identify and filter through correct locations for each supplier, including headquarters, divisions, manufacturing facilities, distribution hubs, and so forth.

AI can also help you understand where the materials, goods, and components that you purchase actually come from.

The best AI solution providers know that while AI can do the lift to identify these connections, they should still be validated by human experts for the most precise view of your network.

Continuous Risk Monitoring and Predictive Alerts

Modern AI supply chain monitoring systems function like digital sentinels, constantly scanning events that could impact your operations. These systems analyze millions of data points every day to sense risks. This data includes, but is not limited to:

- Weather patterns and natural disasters

- Financial health indicators

- Geopolitical instability

- Cyberattacks

- Industrial accidents

Getting alerts for any and every type or risk that could potentially impact your supply chain would become overwhelming.

Here you can use AI to filter out irrelevant, unimportant, and duplicate alerts about the same incident. What you need is a solution that not only monitors risk but also contextualizes these for your specific supply chain.

Alerts should not only be configured to your supply chain, but also to your role within the enterprise. And the alerts should be actionable and important to the receiver. The best AI technologies for supplier risk management leverage multiple layers of filtering for alerting, contextualizing each event in the context of your network operations so you only see what matters.