Having been at the [understandably] sparsely attended MODEX 2020, it was refreshing to see so many people in Atlanta this week for MODEX 2022, almost to the point that standing in line* was also refreshing!

In talking to other attendees and exhibitors as well as in the Q&A during the two panels I participated in, there were several themes that reflect where we are as an industry and as a global community.

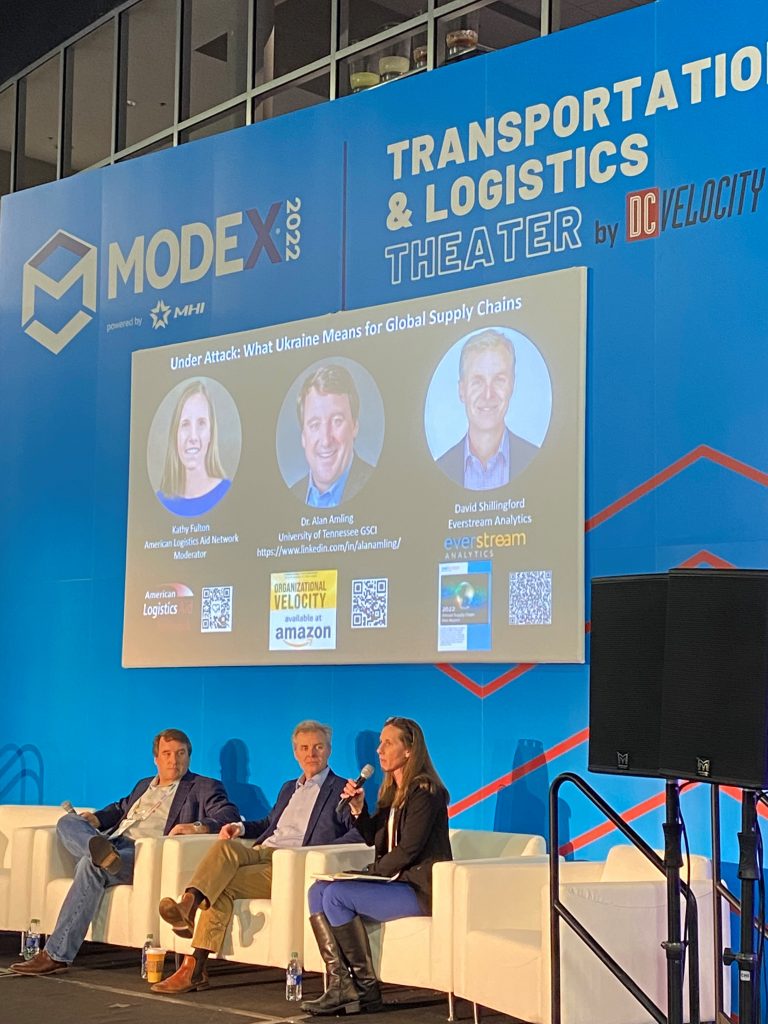

Ukraine

As it has been now for weeks, the topic of Ukraine came up in many conversations. Even if not being discussed, the dark cloud of the Russian invasion was hanging in the air. Ukraine was the topic of the second panel that I participated in along with Kathy Fulton, Executive Director of the American Logistics Aid Network and Alan Amling, Distinguished Fellow at UT’s Supply Chain Institute. Among other things, we discussed unknown Vs known risks, price risk Vs availability risk, how risk propagates through supply chains, global food security and emerging geopolitical risks. The imperative for companies to obtain actionable intelligence (as opposed to news) and to gain visibility to sub-tier suppliers were central themes of the discussion. In response to the question ‘is there anything good to discuss’ and in acknowledgement that this is first and foremost a humanitarian crisis, it was noted that the worst of humanity often brings out the best humanity as the population of other European countries take hundreds of thousands of complete strangers fleeing Ukraine into their houses.

Covid

The keynote address by CNN’s Dr Sanjay Gupta discussed the lessons learned from Covid-19 and what nations across the globe and individual firms can do to prepare and be ready for future pandemic and health-related disruptions. The first panel that I joined also covered lessons from Covid-19 but with a specific focus on supply chain supply and demand disruptions. Along with Kathy Fulton and Rick Blasgen, the past President and CEO of CSCMP, we discussed why and how some companies were better prepared to react to the pandemic, how the level of investment in visibility and risk analytics capabilities has exploded and the role of government in supply chain resilience. The hope is that this represents the bookend to the panel that we did at MODEX in 2020 in which we described the Coronavirus (as it was being called then), its potential spread and its likely impacts on global supply chains.