Every week there are more threatening headlines: the latest surge in a COVID-19 variant, or rising political unrest, or increasing port backups. For supply chain leaders, the latest news triggers questions from all angles; both internal and external. But some companies are better able to get ahead of the news and gain a competitive advantage amid the chaos.

Hearing about a growing virus case count or certain border closures in the news is too late. It means that the competition is likely already ahead of you.

Instead, leading companies get ahead of mainstream media information by relying on sources and methods to obtain actionable information beforehand. Here’s how it works.

Actionable news eclipses general news

This is not a new lesson, and it applies to all causes of supply chain disruptions, but it has been highlighted and underlined most recently by the pandemic. We at Everstream Analytics learned an enormous amount about this as we partnered with the American Logistics Aid Network in developing the ALAN Supply Chain Intelligence Center to provide actionable intelligence to the industry when the pandemic first hit in 2020.

The ways in which COVID-19 impacted supply chains accentuated the difference between general and actionable information. Case counts do not correlate directly to supply chain disruptions. This is largely because it is the decisions and actions of governments, and to a lesser extent companies, that cause shutdowns; and clear lines are drawn between countries, states, cities, and companies with different patterns and timing than the spread of the virus. For example, this is evident as the Chinese government responds to the Omicron surge with a zero-tolerance policy.

Actionable news in practice

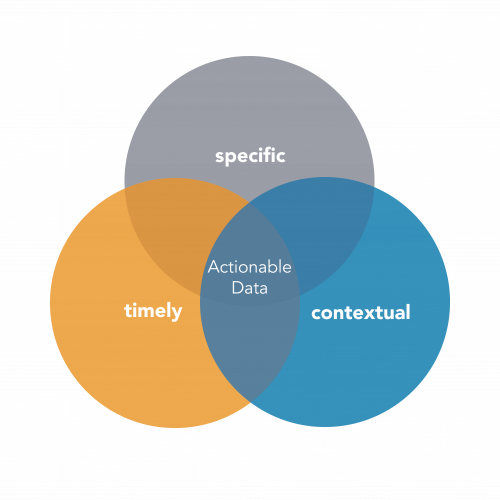

Let’s look at the Omicron virus variant as an example of defining ‘actionable’ information to help prevent disruptions. The actionability of information increases as three variables increase:

- Specific. Knowing about an outbreak in a certain country or region isn’t enough. Dig down to what action the government or corporations have taken and where. Which companies are in an area with mandatory testing? Which are operational but below capacity? Which companies are in an area where specific restrictions, and how do these restrictions apply to different industries? Which companies are closed, be it mandatory or voluntary, and how long will this last?

- Timely. Even media reports are specific, timeliness is a challenge, and it is only a small part of the picture. An analysis of Everstream alerts versus media reports often shows a time gap of weeks from Everstream to news, but even 24 hours can provide a competitive advantage in terms of factory shutdowns and stock prices, to name a few examples.

- Contextual. For news to be actionable it needs context, or “so what?” Is this company a supplier of mine? Do I have a tier-two supplier in the city that has been shut down? How many of my shipments are yet to dock at that port? The list goes on.

Actionable data best practices

To achieve actionable (specific, timely and contextualized) intelligence, the best practice we see is for companies to rely on four information sources.

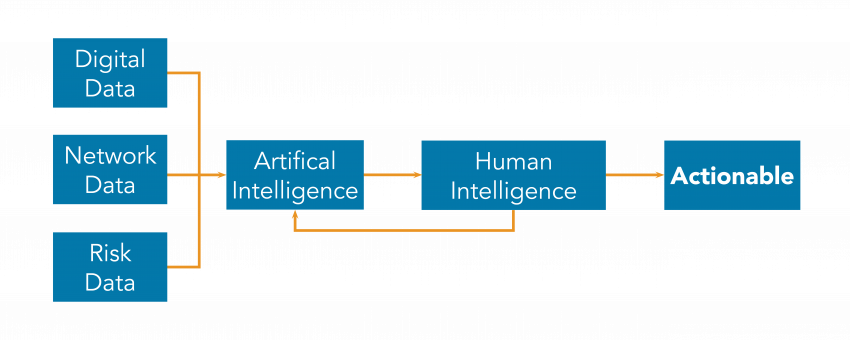

Artificial Intelligence: Global and dynamic coverage of any event that might disrupt a supply chain is a task beyond even the largest human ‘monitoring’ teams. AI is no longer “nice to have” in supply chain analytics, it is table stakes. But to design and deploy it effectively requires years of training data to build models, test, and validate them. The machine must have accurate data on past disruptions and impacts. The data science team must know which AI techniques to employ and how. Success also requires experts to train the models on an ongoing basis.

Human expertise: Experts must train the AI models and apply their own experience and intelligence to the events being generated and categorized by the models. This helps train the models and fill the gaps between what AI can do and what it cannot. Human intelligence is critical for the machine insights to be trusted and therefore actionable by the end user. This team must be experienced in supply chain risks and impacts, while also multi-lingual and located in multiple time zones.

On the ground intelligence: Even with the best human and artificial intelligence processing digital sources, there are many disruptions that will not be reported on, even in local publications. Direct access to on-the-ground sources covers this gap-ground sources. This global network underpins Everstream’s flow of intelligence and unique position in the industry.

Multi-tier supply chain discovery and mapping: Mapping known suppliers and facility locations contextualizes any disruption. The hardest part is to discover unknown suppliers, sub-tier suppliers, and factory locations, and to map this to a product and its Bill of Materials. As with risk intelligence, this can only be done comprehensively through a combination of AI-powered “outside-in” discovery allied with traditional “inside-out” surveys and supplier interactions which become more targeted and timelier when paired with AI-powered discovery.

Supply chain leaders that had these mechanisms in place when the pandemic broke have often outperformed their peers. More have adopted this approach in the last 18 months and all indications are that a large percentage of larger companies plan to follow suit. It sounds daunting but the good news is that these capabilities are fast approaching a standardized plug–and–play capability where initial implementation and “time-to-first-insight” is measured in weeks not months or years.

LEARN MORE ABOUT HOW SUPPLY CHAIN RISK MANAGEMENT WORKS: FREE REPORT