Risk has always been part of procurement. But what if you could see it coming before it hits your supply chain?

Procurement risks can take many forms. From unforeseen fires at a facility, to changing regulations, and geopolitical shifts. At the same time, you need to balance cost, efficiency, and resilience.

Traditionally, procurement teams were reactive to disruption. However, in an increasingly competitive world, that is no longer sufficient.

A recent Gartner survey found that 42% of procurement leaders cited supply disruption as the top threat to success.

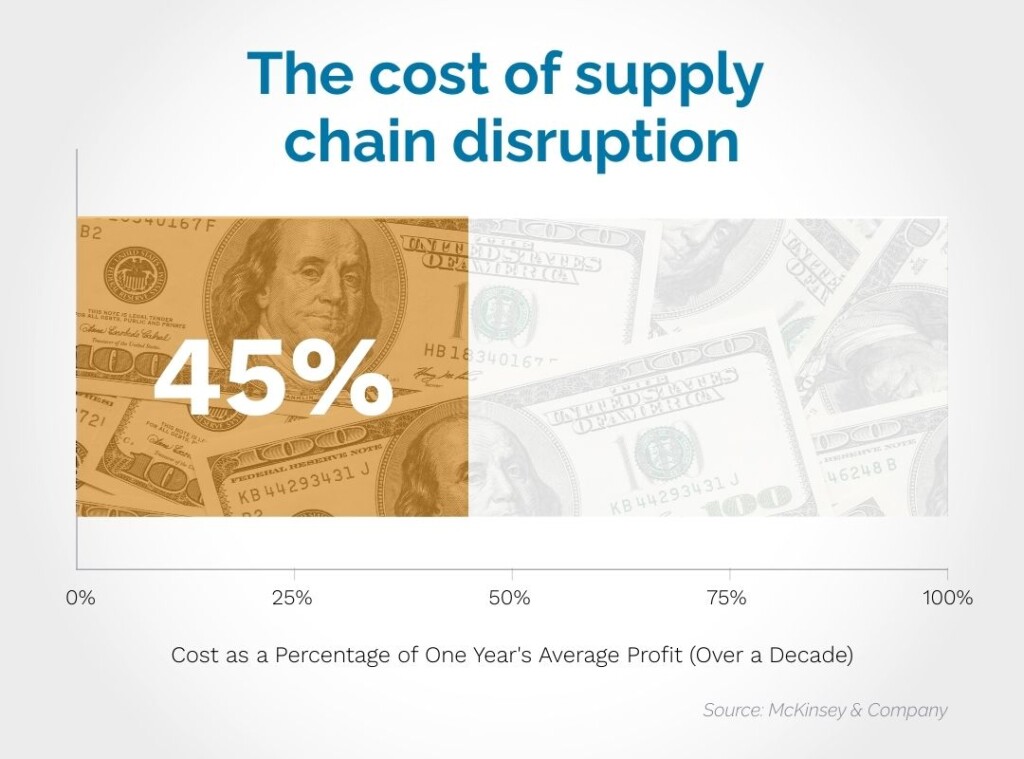

That is unsurprising – disruption is expensive. McKinsey & Company calculates that supply chain disruptions cost 45% of one year’s profits over a ten-year period.

Figure 1: Supply chain disruptions cost 45% of annual profits over a decade

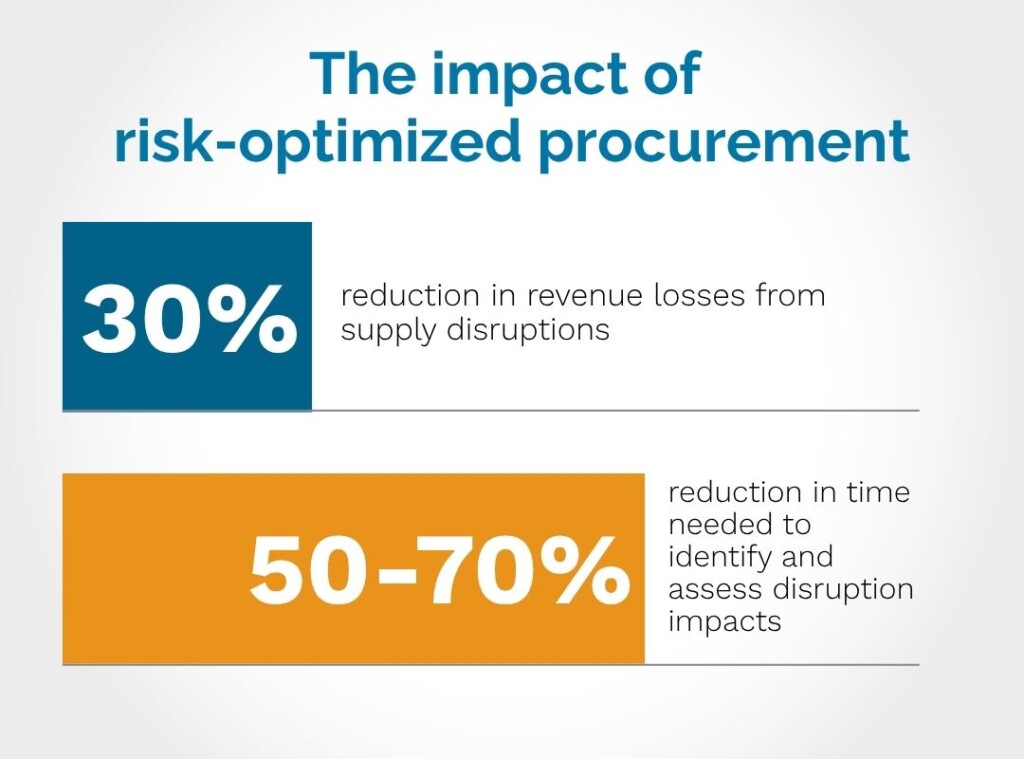

As a result, many procurement leaders have moved to consider supply risk in their sourcing strategies. We call this risk-optimized procurement.

Understanding modern procurement risk

Today’s procurement risks extend far beyond simple supplier failures. They encompass a complex web of interconnected challenges that can cascade through entire supply networks.

Modern global supply chains span multiple tiers, countries, and regulatory environments. A single product might involve dozens of suppliers across different continents. Each of these will bring their own risk profile. As a result, manual supplier assessments and periodic audits are not enough to mitigate risks.

The more components in your products, the more complicated this process is. For example, a single motor vehicle has around 30,000 different pieces, including the nuts and bolts.

Bad weather can impact a supplier in Southeast Asia. This can halt production lines in North America a few days later. Without visibility into these supply network relationships, you cannot see risks until they cause costly problems.

Types of procurement risk

Procurement risks fall into several key categories:

Financial risk: Supplier bankruptcy, cash flow problems, or financial instability that could interrupt supply continuity.

Geopolitical risk: Trade wars, sanctions, political instability, or regulatory changes that affect supplier operations or cross-border trade.

Operational risk: Natural disasters, infrastructure failures, cyber-attacks, or production capacity constraints that disrupt supplier operations.

Compliance risk: Violations of labor standards, environmental regulations, or industry-specific requirements that could result in legal penalties or reputational damage.

Concentration risk: Over-reliance on single suppliers, geographic regions, or transportation routes that create vulnerabilities when disruptions occur.

The cost of reactive risk management

Traditional procurement risk management often operates in reactive mode. This means scrambling to find alternative suppliers, expedite shipments, or adjust production schedules. This reactive approach carries significant costs:

- Revenue loss: Production delays and stockouts directly impact sales and customer satisfaction

- Increased costs: Expedited shipping, premium pricing for alternative suppliers, and overtime labor expenses

- Reputation damage: Supply chain failures can harm brand reputation and customer relationships

- Compliance penalties: Regulatory violations can result in fines and legal complications

How to reduce procurement risk

You cannot reduce procurement risk if you don’t know where the threats are. The ideal way to uncover this information requires a combination of artificial intelligence, human expertise, and internal company data.

These will be used for:

- Networking mapping

- Sub-tier supplier discovery

- Supplier risk assessment and scoring

- Ongoing monitoring

- Predictive alerting

1. Supplier network mapping

The first step in risk-optimized procurement is network mapping. One of AI’s core strengths is its ability to process enormous quantities of data. Here it serves to create a network map of your supply chain.

Once you have mapped your supply chain, you can easily see potential location-based threats.

2. Sub-tier supplier discovery

Your supplier risks do not end at Tier-1 of your supply chain. AI can help map supplier sub-tiers so that you have a much clearer picture of your risk exposure.

AI can analyze billions of trade records, shipping data, and business relationships to create comprehensive maps of supplier networks.

These maps reveal hidden dependencies and concentration risks that manual processes might miss. For instance, AI might discover that multiple Tier-1 suppliers actually depend on the same sub-tier manufacturer, creating a hidden single point of failure.

While AI does most of the lift, human expert validation of sub-tier data is important to provide the most accurate view of your network.

3. Supplier risk assessment and scoring

Once you have mapped your network and sub-tier, you now need to know the baseline risk associated with each supplier. This risk assessment uses both external and internal metrics to create an overall risk score.

How much risk you are willing to tolerate will depend on a number of factors, such as material criticality or scarcity.

You can use weighting to customize risk scores for your company’s risk tolerance and priorities. Some risks may be completely unacceptable, such as the use of forced labor or poor supplier performance. Others, such as having a supplier in a region prone to earthquakes, may be tolerable.

4. Ongoing monitoring

To get ahead of disruption, you need to monitor risk. AI can track thousands of different data sources to monitor risks across your supplier network.

Although AI can scan thousands of data sources, you don’t want to get overwhelmed with alert noise. Advanced AI solutions will contextualize the risk to see if it is relevant to your network and function.

For example, as a procurement professional, you will care deeply about the status of inbound goods needed for production. Therefore, you would want to get alerts about at-risk inbound shipments.

Conversely, it is unlikely to impact your KPIs if a final mile delivery to a customer is late. You would not want alerts for these kinds of risks, since it is up to your logistics colleagues to manage this situation.

The best supply chain risk management software also uses human validation. This removes false positives and ensures you receive targeted risk alerts.

This near real-time monitoring enables you to receive early warnings about potential disruptions.

Predictive alerting

A combination of machine learning algorithms, AI, and data science can be used to analyze historical data patterns to predict future risks. AI is excellent at recognizing patterns and finding anomalies.

However, there are some limitations you need to be aware of. You cannot train a large language model on events that have never occurred before.

AI-powered risk alerting can predict the likelihood of specific risk scenarios and estimate their potential impact. This predictive capability enables procurement teams to make more informed decisions about inventory management.

Companies that do not monitor supplier risk keep an average of 14% excess buffer stock. These are inventory carrying costs that impact your company’s cash flow.