Climate change has the potential to reshape global supply chains in unprecedented ways, more so even than the Covid-19 pandemic, and companies that get ahead of these changes will gain a significant competitive advantage.

Unlike a pandemic, there is no equivalent to a vaccination to address climate change. Actions to minimize or even reverse temperature increases will take many years. But like the pandemic, the impact felt by supply chains because of climate change will be amplified due to the way in which globalization and lean processes have created more fragile supply chains.

Increasing global disruption

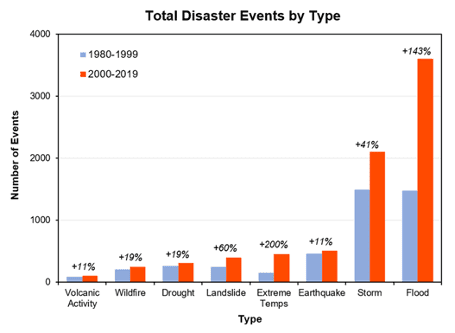

Weather events are one of the primary disruptors in global supply chains. While this has always been true, the frequency of extreme weather events is increasing. In the past decade, the frequency of weather events (disruptors) has increased in every category. This is especially the case in terms of floods, storms (including but not limited to tropical activity), extreme temperatures, and drought.

A recent global study released by the United Nations indicates that since the turn of the century there have been 7,348 major weather/climate events. This is a sharp increase from the previous 20 years when there were 4,212 impactful weather/climate events. The data from this study is in the graph below. There has been an increase in every “event” category when comparing the past 20 years to the final 20 years of the 20th Century. The statistics are clear. The frequency of extreme weather/climate events is increasing across most of the planet, and these events have consequences.

Each event stresses the population (fatalities/injuries, evacuations, loss of property, impacts on employment, forced migration, etc.) and the supply chain (transportation disruptions, business interruptions, infrastructure damage, production outages, worker availability, price fluctuations, capacity constraints, etc.). As the frequency of these events increase, so too do the disruptions within the supply chain.

Extremes in U.S. weather

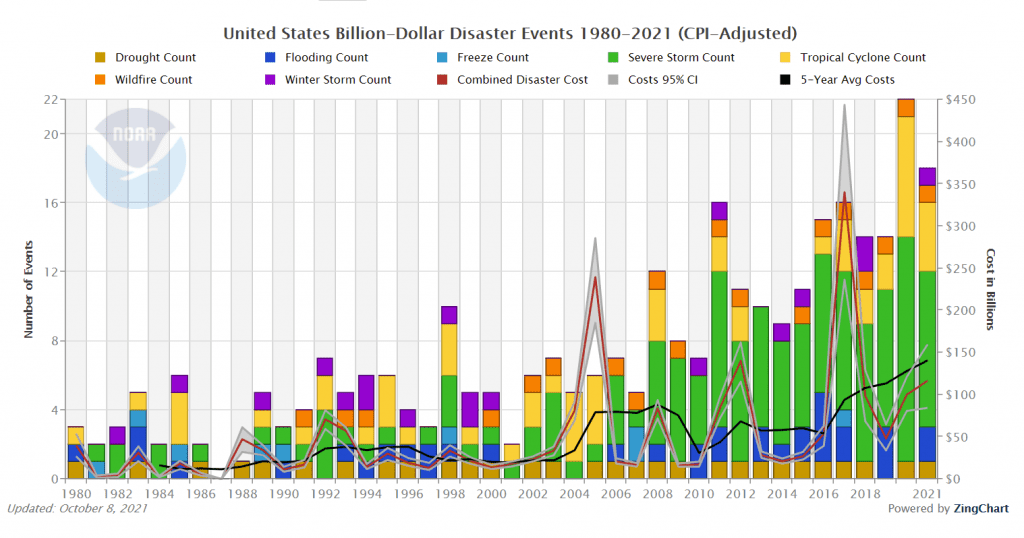

There were 22 weather disaster events in the U.S. in 2020 with losses exceeding $1 billion-USD. This exceeds the prior record of 16 events that occurred in 2011 and 2017. These events included 1 drought, 13 severe storm events, 7 tropical cyclone events, and 1 wildfire event.

The long-term average Consumer Price Index (CPI), which measures average change of consumer goods prices over time, was 7.0 between 1980 – 2020 for billion-dollar or more disaster events. However, the annual average for the most recent five years (2016 – 2020) is 16.2 events (CPI-adjusted). 2020 marks the sixth consecutive year (2015-2020) in which 10 or more billion-dollar weather disaster events occurred in the U.S. So far this year, there have been 18 events in which losses exceeded $1 billion-USD; this is as of October 1 so there are three more months to reach the yearly total.

Even companies located in areas less prone to tropical storms or extreme heat or cold will experience greater volatility and are often less well prepared to cope with extremes. Companies must consider the location of suppliers and their suppliers’ suppliers and whether they are in high-risk areas; the same is true of the logistics networks that connect them.

Many of the most significant supply chain chokepoints face growing risks from too much or too little water. The combination of sea level rises and more severe weather, including high winds, increase risk at ports while navigable waterways are impacted by drought and low water levels; in extreme drought they become unusable.

Higher temperatures increase the risk of wildfires and drought. Crop failures and the closure of waterways are obvious examples of the impact of too little water. As water scarcity grows in certain parts of the globe the impact on production will grow; there are few manufacturing processes that do not rely on water availability and once gone it may never come back.

Higher temperatures will also create more workforce risk. Companies need to pay close attention to worker safety in the face of higher temperatures as well as the legislation that is being developed to protect the workforce.

Focus on the greatest impact

The cost of increasing resilience everywhere in a supply chain is prohibitive so leading companies are using data and analytics to analyze where their risk is greatest and where a disruption would have the most impact on their bottom line. These insights are used to prioritize where measures such as additional inventory or secondary sources of supply are most needed. These insights are also being embedded into planning and execution platforms, making the insights dynamic and increasing companies’ ability to predict and react to near term risk and impact.

As temperatures rise, risk rises. And, the companies best able to analyze the strategic and operational risks due to climate change will gain a significant competitive advantage.

The Everstream Solution

To gain unique insights into strategic and operational risks through network risk assessment & monitoring, be sure to contact us now.