Are supply chain planning disruptions keeping you awake at night? Managing a global supply chain can feel like a never-ending cycle of problems. You face fragmented data silos, fluctuating market conditions, and constant customer demands. Plus, there is the never-ending pressure to optimize inventory levels and reduce costs.

Disruption is a daily occurrence in global supply chains. A truck gets stuck on a highway; critical goods arrive late; supply and demand for particular goods and finished products shift. Supply chain planners are experts at navigating these issues.

Figure 1: Research from Accenture and McKinsey outlining the impact of disruption.

However, larger looming threats can cripple a supply chain, causing production outages, lost sales, and unhappy customers. Reacting to serious issues as they arise keeps you in firefighting mode. If you want to make lasting progress, you must change your approach.

To stay competitive, today’s businesses need supply chains that are proactive, resilient, and, most importantly, agile. But what makes a supply chain agile, and how does technology help achieve that? Read on to learn strategies for building a flexible supply chain. Discover the key features your technology platform needs to keep your business competitive in an unpredictable world.

Agile supply chain planning demystified

What is an agile supply chain?

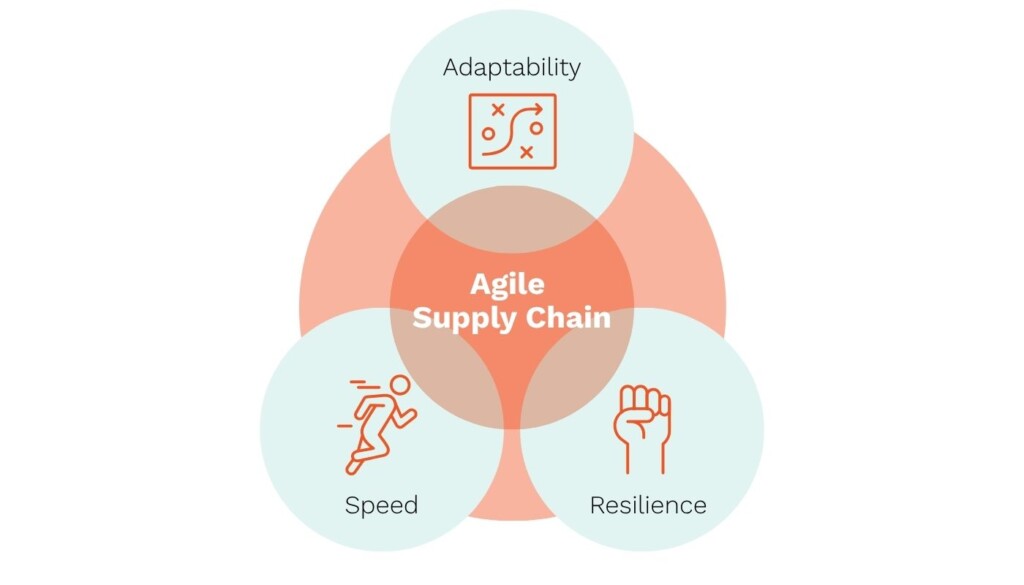

An agile supply chain has three interdependent qualities: speed; adaptability; and resilience. Agility is key to maintaining efficient operations in the face of changing circumstances.

Figure 2: An agile supply chain requires speed, adaptability, and resilience.

Figure 2: An agile supply chain requires speed, adaptability, and resilience.

Global markets are rife with complexity and instability. From extreme weather events to geopolitical uncertainties, disruptions can emerge without warning. Risks are everywhere, and agile supply chains are designed to proactively respond to risk.

The right technology will give you insights that help you make smart decisions in moments of uncertainty. By integrating data from various touchpoints — such as suppliers, transportation channels, and manufacturing facilities — companies can identify disruptions before they escalate.

Build an agile supply chain planning strategy for competitive advantage

If you want to stay agile, your tech platform needs to have the right tools to match your operational goals. These key agile supply chain characteristics can address common pain points.

1. Real-Time Visibility and Unified Data

Data fragmentation is one of the biggest roadblocks to agility. Your supply chain risk management solution should be able to combine data from systems like ERP, supplier management, transportation management, and third-party sources. This will create a complete real-time view.

Why it matters:

When you eliminate data silos, you gain actionable insights into your supply chain. With a centralized view, for example, you can:

- Anticipate delays

- Identify bottlenecks

- Make data-driven decisions to mitigate risks

Key question to ask:

Does the platform consolidate data so you can monitor and manage your entire supply chain in real time?

2. Predictive analytics

Traditional forecasting often fails because it uses fixed models and past trends. These don’t account for rapid changes. Advanced supply chain planning systems use AI to predict demand.

To stay ahead, businesses need more than just forecasts; they need actionable insights. By aligning strategic risk assessments with supply chain uncertainty, companies can proactively prepare for challenges rather than simply react to them.

Why it matters:

Supply chain teams can model smarter “what-if” scenario planning and risk mitigation strategies. This approach shortens response times, so when a disruption does occur, your team already has a plan in place.

Furthermore, predictive analytics allow you to take action before a problem escalates. By leveraging real-time data, you can make informed decisions and mitigate risks to your supply chain.

Key question to ask:

Can the system forecast risks across a number of categories, including supplier outages, risk to raw materials, weather events, geopolitical instability, changing regulations and so forth?