Environmental concerns are also a key issue in mineral procurement. Increased awareness of habitat destruction, water contamination, greenhouse gas emissions, and other environmental consequences of mining and processing has led to strengthened regulations. This further constricts supplies, and companies must now balance environmental responsibility with economic feasibility.

Finally, extracting and refining critical minerals requires advanced technologies and expertise. Many countries lack the infrastructure or technological knowledge to quickly get their operations functioning, creating a dependence on already-established players. Again, this results in a reduction of available supplies and increased vulnerability to geopolitical pressures.

To address these challenges, businesses can’t just rely on what’s worked previously. Instead, companies should focus on investing in alternative sources, improving recycling methods, and collaborations across industries and government to create sustainable procurement methods.

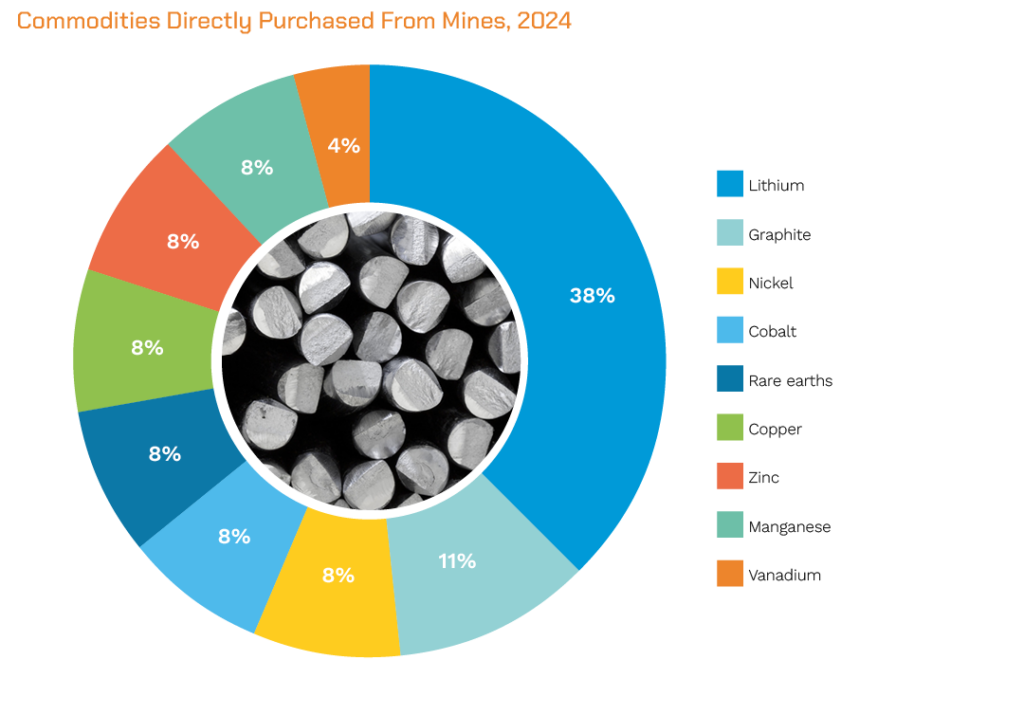

Figure 1: Critical minerals with increased procurement risk in 2025

Geopolitical risks in supply chain management

Beyond procurement itself, global politics can pose significant challenges to supply chains. Resource nationalism, where governments prioritize the domestic use of critical minerals or imposing other export restrictions on key products, can drive up the cost of business quickly. Similarly, global trade wars and tariffs, can further drive up costs and complexities in sourcing materials. Economic sanctions that target specific nations or organizations can cause sudden supply shortages of any necessary components, leaving dependent companies scrambling for alternative suppliers.

Geopolitical risks can make it difficult to create accurate long-term plans or investments, as situations are continuously changing. For example, some critical minerals are sourced from politically unstable regions, meaning that businesses must account for sudden shortages or disruptions due to political unrest, corruption, or conflicts. Furthermore, reliance on critical minerals or components that are sourced or created using unethical practices, such as child or forced labor, creates compliance and governance risks.

Finally, many critical minerals and metals are only found in specific places around the world. For example, DRC dominates cobalt supply, while Chile and Australia are major producers of lithium. Similarly, certain countries have spent years building the infrastructure to dominate the production of certain components that are key within the fabrication of end products. The dependence on a handful of countries for such a significant part of a supply chain means that organizations are at the mercy of positive geopolitical relationships, stable governments, and favorable market practices. When this stability is disrupted – such as the US-China rivalry – industries worldwide are subject to uncertainty and outside pressures.

Impact on supply chains

Procurement challenges and geopolitical tensions can have several knock-on effects in global supply chains across industries. Supply chain disruptions caused by geopolitical events can lead to supply chain bottlenecks, devastating the availability of key components and contributing to extreme price volatility. This can be difficult for businesses to adapt to, especially as they attempt to maintain positive relationships with their customers while quickly finding the best – and cheapest – solution in the face of delays. Additionally, these delays can stymie industries and markets. For example, automotive production was significantly delayed by the semiconductor shortage a few years ago. Further disruptions can seriously slow global progress toward technological and environmental goals.

From a regulatory perspective, evolving international trade regulations further compliance supply chain risk management. Governments are increasingly enacting policies to ensure ethical sourcing, environmental sustainability, and national security, especially when it comes to critical minerals and metals. Businesses are often subject to overlapping global regulations, making them responsible for their own practices, as well as the practices of their suppliers. These additional compliance burdens mean that organizations must have a clear view into their end-to-end supply chain at all times, ensuring that they can take quick action when an emerging risk appears.

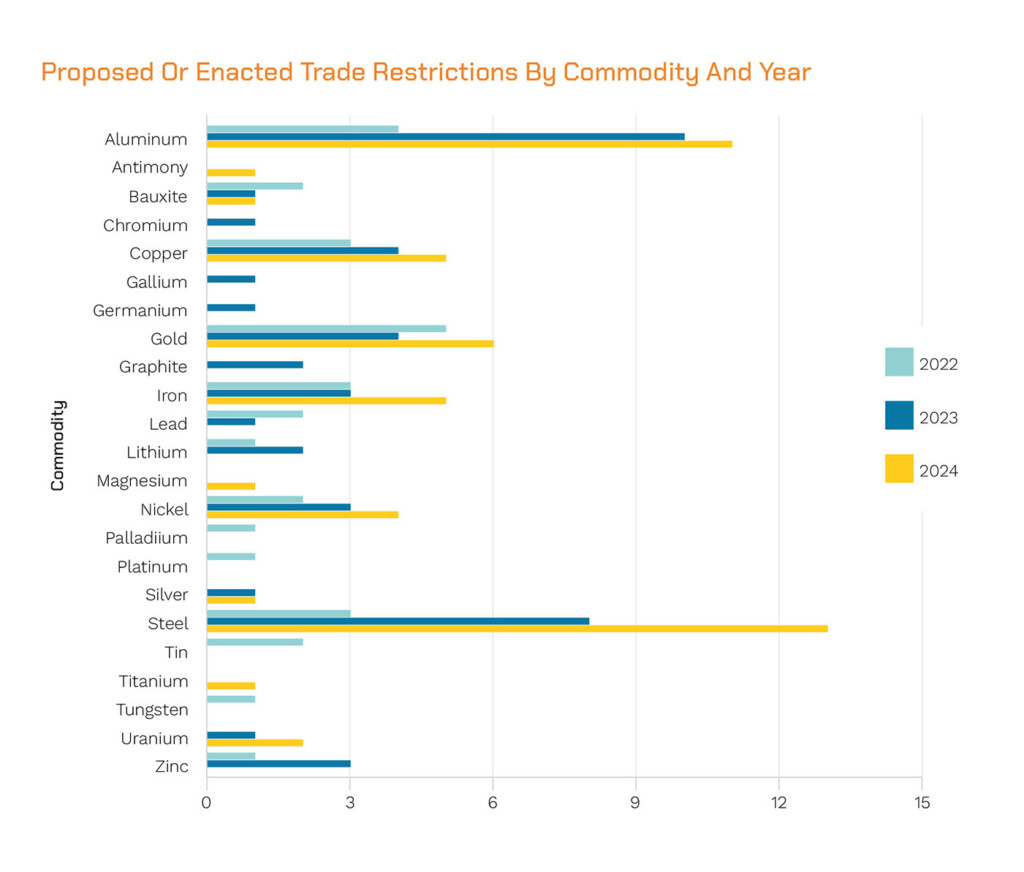

Figure 2: Outlined trade restrictions and further geopolitical instability against critical mineral procurement over last few years

Figure 2: Outlined trade restrictions and further geopolitical instability against critical mineral procurement over last few years

Next steps

Managing procurement challenges and geopolitical risks is an ongoing process which requires a multifaceted approach that balances supplier diversification, sustainability, and technological innovation. Adopting a proactive strategy will aid in creating supply chain resilience and minimizing vulnerabilities. Here are some strategies to consider when creating an effective supply chain risk management plan:

- Diversification. Where possible, try to diversify suppliers across multiple regions to reduce dependence on dominant players. Building partnerships with more than one supplier (and its associated nation) strengthens supply chain security, and gives your organization viable alternatives in case your main supplier is in trouble.

- Invest in recycling. Recycling and recovery initiatives play a crucial role in reducing reliance on newly mined materials. Investing early in sustainable supply sources, alongside traditional mineral sourcing, minimizes supply chain uncertainty and reduces environmental impacts.

- Invest in technological advancements. Investing in the research and development of alternative materials or efficient extraction methods is another key strategy to reduce singular dependencies and enhance operational efficiency.

- Monitor your supply chain. Above all else, it’s critical to understand what’s going on in your supply chain. How are political, economic, climate, and sustainability risks impacting your suppliers – and how might it impact your business? Using advanced analytics, powered by AI, can empower your supply chain management team to make the right decisions at the right time, minimizing the effect of emerging disruptions and mitigating vulnerabilities.

Supply chain challenges, such as the procurement of critical minerals and geopolitical impacts on global supply chains, will never become simpler. However, by addressing these key risks and adopting proactive management strategies, organizations can enhance resilience, reduce uncertainty, and keep business running as smoothly as possible.

Figure 2: Outlined trade restrictions and further geopolitical instability against critical mineral procurement over last few years

Figure 2: Outlined trade restrictions and further geopolitical instability against critical mineral procurement over last few years